Reconfigurable manufacturing systems are designed to quickly adapt their hardware and software to produce different products or respond to changes in market demand, emphasizing modularity and scalability. Flexible manufacturing systems, on the other hand, prioritize the ability to handle a variety of product types through adaptable tooling and automation without significant reconfiguration. The key distinction lies in reconfigurable manufacturing's focus on rapid structural changes to optimize production flow, whereas flexible manufacturing centers on flexibility in operation within a fixed system layout.

Table of Comparison

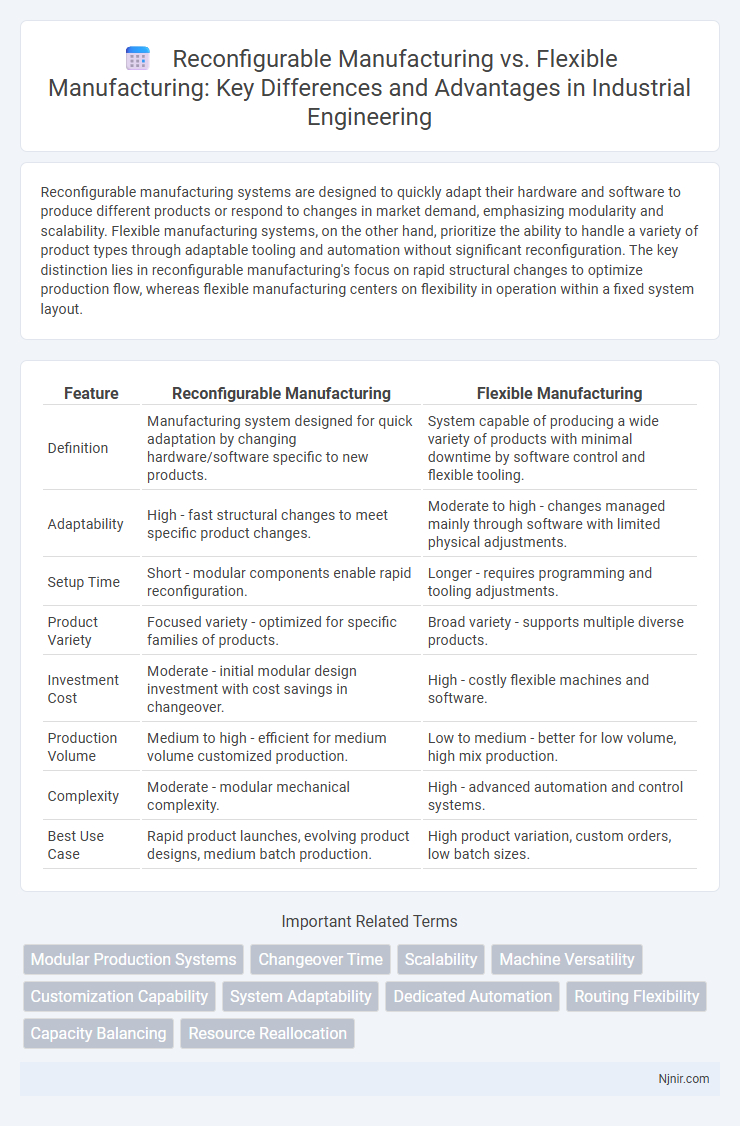

| Feature | Reconfigurable Manufacturing | Flexible Manufacturing |

|---|---|---|

| Definition | Manufacturing system designed for quick adaptation by changing hardware/software specific to new products. | System capable of producing a wide variety of products with minimal downtime by software control and flexible tooling. |

| Adaptability | High - fast structural changes to meet specific product changes. | Moderate to high - changes managed mainly through software with limited physical adjustments. |

| Setup Time | Short - modular components enable rapid reconfiguration. | Longer - requires programming and tooling adjustments. |

| Product Variety | Focused variety - optimized for specific families of products. | Broad variety - supports multiple diverse products. |

| Investment Cost | Moderate - initial modular design investment with cost savings in changeover. | High - costly flexible machines and software. |

| Production Volume | Medium to high - efficient for medium volume customized production. | Low to medium - better for low volume, high mix production. |

| Complexity | Moderate - modular mechanical complexity. | High - advanced automation and control systems. |

| Best Use Case | Rapid product launches, evolving product designs, medium batch production. | High product variation, custom orders, low batch sizes. |

Introduction to Reconfigurable and Flexible Manufacturing

Reconfigurable manufacturing systems (RMS) are designed to rapidly adjust production capacity and functionality through modular components to meet evolving market demands and product variations. Flexible manufacturing systems (FMS) emphasize the ability to produce a wide variety of products without extensive retooling by using automated machinery and computer-controlled processes. RMS prioritizes scalability and quick adaptability, whereas FMS focuses on versatility and minimizing downtime during transitions between different product types.

Core Principles of Reconfigurable Manufacturing Systems

Reconfigurable manufacturing systems (RMS) emphasize modularity, scalability, and integrability to rapidly adjust production capacity and functionality in response to market changes, contrasting with the broader adaptability focus of flexible manufacturing systems (FMS). Core principles of RMS include customization of core system components for specific tasks, swift reconfiguration through modular hardware and software, and real-time system monitoring to optimize performance. These principles enable manufacturers to efficiently scale operations and modify processes while minimizing downtime and costs.

Key Features of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) feature automated machinery, computer-controlled production processes, and modular equipment designed to adapt quickly to variations in product types and volumes. These systems enable real-time scheduling and inventory management, supporting small batch sizes and frequent product changes without significant downtime. Unlike reconfigurable manufacturing, which emphasizes rapid system scalability and reconfiguration for specific product lines, FMS prioritizes versatility and efficient resource utilization across diverse manufacturing tasks.

Technological Foundations: RMS vs FMS

Reconfigurable Manufacturing Systems (RMS) leverage modular hardware and software architectures designed for rapid scalability and customization, enabling quick adaptation to new product variants. Flexible Manufacturing Systems (FMS) integrate automated machinery and computer-controlled processes allowing simultaneous production of different parts without physical changes. RMS emphasizes real-time reconfiguration capabilities and targeted agility, while FMS prioritizes broad manufacturing versatility and high automation levels.

Adaptability and Customization Capabilities

Reconfigurable manufacturing systems (RMS) offer high adaptability by allowing rapid structural changes to equipment and processes to accommodate new product types and volumes. Flexible manufacturing systems (FMS) provide customization capabilities through programmable machines that can switch between different part variants without extensive setup times. RMS excels in scalability and reconfiguration speed, while FMS prioritizes variation in product designs within existing setups.

Cost Implications and Investment Considerations

Reconfigurable manufacturing systems (RMS) require higher initial capital investment due to modular hardware and software designed for quick adjustments, resulting in significant cost savings over time through reduced downtime and enhanced scalability. Flexible manufacturing systems (FMS) generally entail lower upfront costs but can lead to higher operational expenses because of less optimized resource utilization and longer changeover times. Investment considerations for RMS focus on long-term adaptability and capacity expansion, whereas FMS investments prioritize short-term versatility and lower entry barriers.

Scalability and Production Volume Management

Reconfigurable manufacturing systems (RMS) offer rapid scalability by enabling quick reconfiguration of equipment and processes to match changing production volumes and product variants, making them ideal for fluctuating demand and customized production. Flexible manufacturing systems (FMS) provide versatility through automation and tool changes, supporting moderate scalability but often at higher setup times and costs compared to RMS. RMS excels in efficiently managing variable production volumes by structurally adapting to new requirements, while FMS relies more on software flexibility and machine versatility without structural changes.

Implementation Challenges in Modern Industry

Reconfigurable manufacturing systems face implementation challenges such as high initial capital costs and the complexity of designing modular equipment that can be quickly adapted to changing product types. Flexible manufacturing systems struggle with integrating sophisticated automation technologies and maintaining production efficiency when switching between diverse product configurations. Both approaches require advanced workforce training and robust IT infrastructure to manage real-time data and ensure seamless operation in modern industry environments.

Case Studies: Industrial Applications and Outcomes

Case studies in reconfigurable manufacturing highlight its ability to quickly adapt production lines for new product variants, resulting in reduced downtime and enhanced customization for industries like automotive and electronics. Flexible manufacturing systems demonstrate versatility by efficiently handling small batch sizes and product diversity in sectors such as aerospace and medical devices, leading to increased productivity and cost savings. Industrial outcomes reveal reconfigurable systems excel in rapid scalability, while flexible systems prioritize process variation without extensive retooling, influencing decision-making in manufacturing strategy.

Future Trends in Manufacturing System Evolution

Reconfigurable manufacturing emphasizes rapid adaptability through modular hardware and software, enabling quick reconfiguration to meet changing production requirements, while flexible manufacturing prioritizes versatility by handling a variety of product types within fixed system configurations. Future trends in manufacturing system evolution highlight increased integration of digital twins, AI-driven optimization, and cyber-physical systems in reconfigurable manufacturing to enhance responsiveness and scalability. Flexible manufacturing systems will increasingly leverage IoT connectivity and advanced robotics to improve customization and operational efficiency across diverse product lines.

Modular Production Systems

Reconfigurable manufacturing systems emphasize modular production units designed for rapid scalability and customization, whereas flexible manufacturing systems prioritize adaptability across diverse product types without extensive physical changes.

Changeover Time

Reconfigurable manufacturing significantly reduces changeover time by allowing rapid hardware and software adjustments, whereas flexible manufacturing systems require longer reprogramming and setup periods for changeover.

Scalability

Reconfigurable manufacturing systems enable rapid scalability by allowing quick adjustments of production capacity and functionality, whereas flexible manufacturing systems offer scalability primarily through the ability to produce a wide variety of products without significant reconfiguration.

Machine Versatility

Reconfigurable manufacturing offers rapid machine versatility through modular components tailored for specific product changes, whereas flexible manufacturing provides broader machine adaptability capable of handling diverse product types without major reconfiguration.

Customization Capability

Reconfigurable manufacturing offers superior customization capability by enabling rapid adjustments to production systems for specific product changes, whereas flexible manufacturing provides broader but less targeted adaptability across varied product types.

System Adaptability

Reconfigurable manufacturing systems enable rapid structural adjustments to production layout for specific product changes, while flexible manufacturing systems adapt more broadly to varied product types without significant hardware modifications.

Dedicated Automation

Reconfigurable manufacturing systems use dedicated automation designed for rapid adaptation to changing product demands, whereas flexible manufacturing relies on general-purpose automation for broader but slower adjustments.

Routing Flexibility

Reconfigurable manufacturing offers limited routing flexibility with fixed machine layouts, whereas flexible manufacturing systems provide high routing flexibility through adaptable machine configurations and automated material handling.

Capacity Balancing

Reconfigurable manufacturing systems enable rapid capacity balancing by modularly adjusting production lines to meet variable demand, whereas flexible manufacturing systems optimize capacity through versatile equipment capable of handling diverse tasks without structural changes.

Resource Reallocation

Reconfigurable manufacturing enables rapid resource reallocation through modular equipment and scalable systems, enhancing adaptability to product variations compared to the more generalized but less swiftly adjustable resource allocation in flexible manufacturing.

Reconfigurable manufacturing vs Flexible manufacturing Infographic

njnir.com

njnir.com