Additive manufacturing builds components layer-by-layer, enabling complex geometries and reduced material waste compared to traditional subtractive processes. Traditional manufacturing relies on machining, casting, or molding, often requiring extensive tooling and longer lead times for production. The choice between these methods impacts cost efficiency, design flexibility, and production speed in industrial engineering projects.

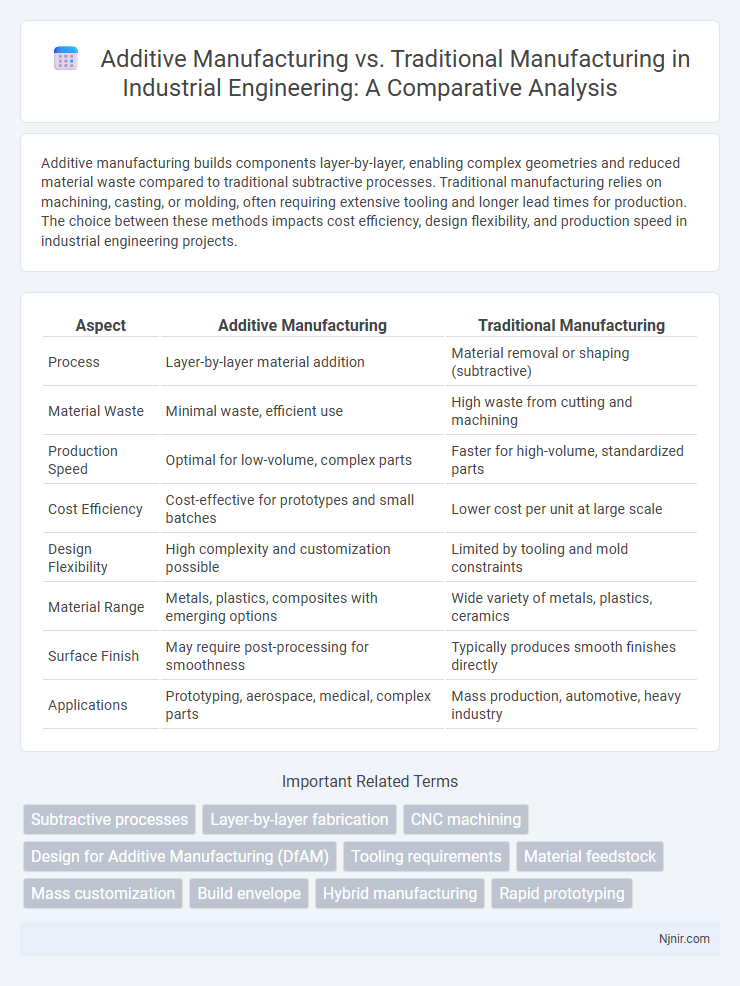

Table of Comparison

| Aspect | Additive Manufacturing | Traditional Manufacturing |

|---|---|---|

| Process | Layer-by-layer material addition | Material removal or shaping (subtractive) |

| Material Waste | Minimal waste, efficient use | High waste from cutting and machining |

| Production Speed | Optimal for low-volume, complex parts | Faster for high-volume, standardized parts |

| Cost Efficiency | Cost-effective for prototypes and small batches | Lower cost per unit at large scale |

| Design Flexibility | High complexity and customization possible | Limited by tooling and mold constraints |

| Material Range | Metals, plastics, composites with emerging options | Wide variety of metals, plastics, ceramics |

| Surface Finish | May require post-processing for smoothness | Typically produces smooth finishes directly |

| Applications | Prototyping, aerospace, medical, complex parts | Mass production, automotive, heavy industry |

Overview of Additive and Traditional Manufacturing

Additive manufacturing, also known as 3D printing, builds objects layer by layer directly from digital models, enabling complex geometries and rapid prototyping with minimal material waste. Traditional manufacturing techniques, such as machining, casting, and molding, rely on subtractive or formative processes that often require specialized tooling and longer setup times. Additive manufacturing excels in customization and low-volume production, while traditional methods remain cost-effective for large-scale manufacturing and standardized parts.

Core Principles and Techniques

Additive manufacturing builds objects layer by layer using digital 3D models, enabling complex geometries and material efficiency, while traditional manufacturing relies on subtractive processes such as machining, casting, and forging, which shape materials by removing or deforming them. Key techniques in additive manufacturing include selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA), contrasting with CNC machining, injection molding, and stamping in traditional methods. The core principle of additive manufacturing emphasizes customization and reduced waste, whereas traditional manufacturing prioritizes high-volume production and material strength.

Material Compatibility and Selection

Additive manufacturing offers greater material versatility by enabling the use of complex composites, polymers, and metals that can be precisely layered, unlike traditional manufacturing which often relies on bulk materials and is limited by subtractive or formative constraints. Traditional manufacturing excels in established metals and plastics with well-characterized mechanical properties, making it suitable for large-scale production where material homogeneity is critical. Material selection in additive manufacturing prioritizes layer adhesion and thermal properties, while traditional methods focus on durability and machinability to meet performance standards.

Production Speed and Efficiency

Additive manufacturing enables rapid prototyping and production by building components layer-by-layer, reducing material waste and minimizing setup times compared to traditional manufacturing's subtractive processes. Traditional manufacturing, such as machining or casting, often requires longer tooling and setup phases but excels in high-volume production efficiency once these stages are complete. The faster iteration cycle in additive manufacturing significantly enhances production agility, while traditional methods maintain advantages in consistency and scale for mass production.

Design Flexibility and Complexity

Additive manufacturing offers unparalleled design flexibility, enabling the creation of intricate geometries and complex internal structures that are difficult or impossible to achieve with traditional manufacturing methods. Traditional manufacturing typically relies on subtractive processes, limiting design complexity due to tooling constraints and material waste considerations. The ability of additive manufacturing to produce lightweight, optimized parts with minimal material usage significantly enhances innovation in industries like aerospace and biomedical engineering.

Cost Analysis and Economic Impact

Additive manufacturing reduces material wastage and lowers inventory costs through on-demand production, leading to significant savings in prototyping and small-batch components compared to traditional manufacturing. Traditional manufacturing benefits from economies of scale with lower per-unit costs in mass production but incurs higher upfront tooling and setup expenses. The economic impact of additive manufacturing fosters innovation and customization, while traditional methods dominate high-volume production due to established cost efficiency.

Quality Control and Consistency

Additive manufacturing enables precise layer-by-layer construction, resulting in high-quality parts with complex geometries and minimized material waste, improving consistency through digital process controls. Traditional manufacturing relies on established production techniques where quality control involves rigorous inspection and calibration of tooling, but can face variability due to material inconsistencies and mechanical wear over time. Advances in additive technology improve repeatability and reduce defects, whereas traditional methods benefit from extensive process standardization supporting large-scale production with predictable quality outcomes.

Environmental and Sustainability Considerations

Additive manufacturing reduces material waste by building products layer-by-layer, promoting resource efficiency compared to traditional subtractive processes that often generate significant scrap. Energy consumption in additive manufacturing can be lower for small batch or complex parts, decreasing the carbon footprint relative to large-scale traditional manufacturing. However, the sustainability benefits depend on factors like feedstock material recyclability, energy sources, and Lifecycle Assessment (LCA) results for both manufacturing methods.

Applications Across Industries

Additive manufacturing excels in aerospace, automotive, and healthcare by enabling rapid prototyping, complex geometries, and customized implants, which traditional manufacturing struggles to achieve efficiently. Traditional manufacturing remains dominant in high-volume production of standardized parts across industries such as consumer goods, construction, and electronics due to its cost-effectiveness and established supply chains. Both methods are increasingly integrated in industry 4.0 environments to optimize production flexibility and product innovation.

Future Trends in Manufacturing Technologies

Additive manufacturing is poised to revolutionize future manufacturing technologies by enabling complex geometries, reduced material waste, and rapid prototyping, which traditional manufacturing methods struggle to achieve efficiently. Advances in materials science, including metal and polymer composites, enhance the mechanical properties and application scopes of 3D-printed parts, making additive manufacturing increasingly viable for aerospace, automotive, and healthcare industries. Integration with artificial intelligence and IoT-driven automation will further optimize production processes, increasing customization capabilities and reducing lead times compared to traditional subtractive and formative manufacturing techniques.

Subtractive processes

Additive manufacturing builds objects layer-by-layer using materials like polymers or metals, whereas traditional subtractive manufacturing removes material from a solid block through machining processes such as milling, turning, or drilling.

Layer-by-layer fabrication

Additive manufacturing builds parts through precise layer-by-layer fabrication, enabling complex geometries and reduced material waste compared to traditional subtractive manufacturing methods.

CNC machining

Additive manufacturing builds complex parts layer-by-layer from digital models, offering rapid prototyping and material efficiency, while traditional CNC machining removes material from solid blocks, providing high precision and superior surface finish for metal components.

Design for Additive Manufacturing (DfAM)

Design for Additive Manufacturing (DfAM) leverages 3D printing's layer-by-layer construction to create complex, lightweight structures and customized geometries that traditional manufacturing methods cannot efficiently achieve.

Tooling requirements

Additive manufacturing significantly reduces tooling requirements by enabling direct part fabrication from digital models, whereas traditional manufacturing relies heavily on custom molds, dies, and fixtures.

Material feedstock

Additive manufacturing utilizes powdered or filament-based material feedstock enabling complex geometries and minimal waste, whereas traditional manufacturing relies on bulk raw materials often resulting in higher material loss and limited design flexibility.

Mass customization

Additive manufacturing enables mass customization by allowing cost-effective production of complex, tailored designs at scale, whereas traditional manufacturing relies on standardized processes with higher costs and longer lead times for customized products.

Build envelope

Additive manufacturing enables larger and more complex build envelopes compared to traditional manufacturing, which is limited by tooling and machine size constraints.

Hybrid manufacturing

Hybrid manufacturing combines additive manufacturing's precision and complex geometries with traditional manufacturing's speed and material versatility to optimize production efficiency and product quality.

Rapid prototyping

Additive manufacturing enables faster and cost-effective rapid prototyping by building complex designs layer-by-layer, whereas traditional manufacturing relies on slower, tool-intensive processes.

Additive manufacturing vs Traditional manufacturing Infographic

njnir.com

njnir.com