Autonomous robots operate independently in industrial environments, performing complex tasks without human intervention, which maximizes efficiency and reduces labor costs. Collaborative robots, or cobots, work alongside human operators, enhancing safety and flexibility by assisting with repetitive or precision tasks. Both types of robots revolutionize manufacturing processes but differ in application, where autonomous robots are ideal for high-volume, repetitive tasks and cobots excel in adaptable, human-robot interaction scenarios.

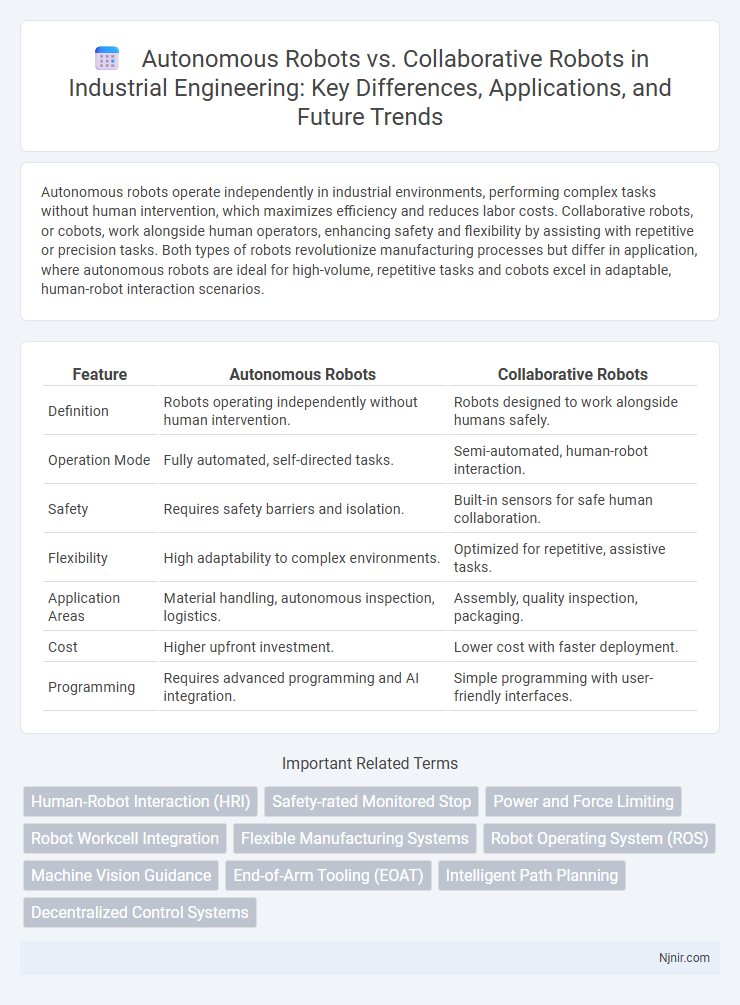

Table of Comparison

| Feature | Autonomous Robots | Collaborative Robots |

|---|---|---|

| Definition | Robots operating independently without human intervention. | Robots designed to work alongside humans safely. |

| Operation Mode | Fully automated, self-directed tasks. | Semi-automated, human-robot interaction. |

| Safety | Requires safety barriers and isolation. | Built-in sensors for safe human collaboration. |

| Flexibility | High adaptability to complex environments. | Optimized for repetitive, assistive tasks. |

| Application Areas | Material handling, autonomous inspection, logistics. | Assembly, quality inspection, packaging. |

| Cost | Higher upfront investment. | Lower cost with faster deployment. |

| Programming | Requires advanced programming and AI integration. | Simple programming with user-friendly interfaces. |

Introduction to Autonomous and Collaborative Robots in Industry

Autonomous robots operate independently using advanced sensors, AI, and machine learning to perform complex tasks with minimal human intervention, enhancing efficiency in manufacturing and logistics. Collaborative robots (cobots) are designed to work safely alongside human workers, equipped with sensors and safety features to support tasks such as assembly, quality control, and material handling. Both autonomous and collaborative robots are transforming industries by increasing productivity, reducing errors, and optimizing operational workflows.

Core Differences Between Autonomous and Collaborative Robots

Autonomous robots operate independently, using advanced sensors and AI algorithms to perform tasks without human intervention, primarily in structured or predefined environments. Collaborative robots, or cobots, are designed to work alongside humans safely, equipped with sensors and force feedback to detect and respond to human presence in shared workspaces. The core difference lies in autonomy level: autonomous robots handle tasks solo with full decision-making capabilities, whereas collaborative robots assist humans by enhancing flexibility and safety in dynamic environments.

Applications of Autonomous Robots in Industrial Settings

Autonomous robots excel in industrial settings by performing complex tasks like automated material handling, precision welding, and quality inspection without human intervention. These robots leverage advanced sensors and AI algorithms to navigate dynamic factory environments and adapt to changing production lines. Their ability to operate continuously enhances efficiency, reduces labor costs, and improves safety in manufacturing processes.

Collaborative Robots: Key Industrial Use Cases

Collaborative robots (cobots) are extensively used in manufacturing for tasks such as precision assembly, quality inspection, and machine tending, enhancing productivity while ensuring safety alongside human workers. In automotive industries, cobots facilitate complex, repetitive tasks like bolt fastening and painting, reducing ergonomic strain and increasing efficiency. Their flexibility and ease of programming make cobots ideal for pharmaceuticals and electronics production, where they handle delicate components with high accuracy.

Safety Considerations: Autonomous vs Collaborative Robotics

Autonomous robots operate independently with advanced sensors and AI to navigate complex environments, requiring robust safety protocols to prevent collisions and errors in unpredictable settings. Collaborative robots (cobots) are designed to work alongside humans, incorporating built-in safety features such as force-limited joints and immediate stop functions to minimize injury risks during close human-robot interaction. Safety considerations for autonomous robots emphasize environmental control and fail-safe mechanisms, while cobots focus on real-time responsiveness and ergonomic design to ensure safe and efficient human collaboration.

Integration Challenges in Industrial Environments

Autonomous robots require advanced sensor integration, real-time data processing, and robust navigation systems to operate independently, posing significant challenges for seamless deployment in dynamic industrial environments. Collaborative robots, designed to work alongside human operators, demand precise safety protocols, responsive motion control, and intuitive human-machine interfaces, which complicate their integration with existing workflows. Both types necessitate tailored software architectures and interoperability solutions to ensure effective communication with factory management systems and optimize productivity.

Productivity and Efficiency: Comparative Analysis

Autonomous robots operate independently, executing pre-programmed tasks with high precision, significantly boosting productivity in repetitive and hazardous environments. Collaborative robots (cobots) work alongside human operators, enhancing efficiency by combining human adaptability with robotic accuracy, optimizing task flexibility and reducing cycle times. Comparative studies show that integrating cobots in mixed workflows often results in a 20-30% increase in overall productivity compared to fully autonomous systems, due to improved task adaptability and reduced downtime.

Human-Robot Interaction in Industrial Automation

Autonomous robots in industrial automation operate independently with minimal human intervention, leveraging advanced sensors and AI to perform complex tasks efficiently and safely. Collaborative robots (cobots) are designed for direct human-robot interaction, enhancing productivity by working alongside human operators with built-in safety features like force sensors and adaptive motion control. Effective human-robot interaction in industrial settings improves workflow flexibility, reduces accidents, and supports seamless integration of automated systems in manufacturing processes.

Cost Implications and ROI: Autonomous vs Collaborative Robots

Autonomous robots generally require higher upfront investment due to advanced sensors, AI, and infrastructure needs, but they offer significant cost savings through continuous operation and reduced labor expenses. Collaborative robots (cobots) have lower initial costs and faster deployment, enabling small to medium businesses to quickly realize ROI by improving productivity and flexibility in shared human-robot workspaces. Evaluating total cost of ownership and specific application efficiency is essential to determine which robotic solution delivers optimal ROI in manufacturing and industrial automation environments.

Future Trends in Industrial Robotics: Autonomy and Collaboration

Future trends in industrial robotics emphasize increased autonomy in autonomous robots, enabling them to perform complex tasks without human intervention through advanced AI and machine learning algorithms. Collaborative robots (cobots) are evolving to enhance real-time human-robot interaction with improved sensor technology and safety features, facilitating seamless teamwork on factory floors. Integration of 5G connectivity and edge computing further accelerates the efficiency and responsiveness of both autonomous and collaborative robots in smart manufacturing environments.

Human-Robot Interaction (HRI)

Autonomous robots operate independently with minimal human input, whereas collaborative robots are designed for direct Human-Robot Interaction (HRI), enabling safe and intuitive teamwork in shared environments.

Safety-rated Monitored Stop

Safety-rated Monitored Stop enhances Collaborative Robots' operational safety by temporarily halting robot movement when a human enters the workspace, unlike Autonomous Robots that operate independently without continuous human interaction.

Power and Force Limiting

Autonomous robots operate with high power and force for independent tasks, while collaborative robots prioritize power and force limiting to ensure safe human interaction.

Robot Workcell Integration

Autonomous robots operate independently within robot workcells, while collaborative robots integrate seamlessly with human workers for flexible, interactive tasks enhancing productivity and safety.

Flexible Manufacturing Systems

Autonomous robots enhance flexible manufacturing systems by independently performing complex tasks, while collaborative robots improve adaptability through safe human-robot interaction in dynamic production environments.

Robot Operating System (ROS)

Robot Operating System (ROS) enables both autonomous robots with advanced independent decision-making and collaborative robots designed for seamless human-robot interaction by providing standardized middleware, tools, and libraries for perception, control, and communication.

Machine Vision Guidance

Machine vision guidance enables autonomous robots to perform complex tasks independently, while collaborative robots rely on vision systems to safely interact and assist human operators in shared environments.

End-of-Arm Tooling (EOAT)

End-of-Arm Tooling (EOAT) for autonomous robots is designed for high-precision, repetitive tasks with minimal human intervention, while collaborative robots use adaptive EOAT to safely interact with humans in dynamic environments.

Intelligent Path Planning

Intelligent path planning in autonomous robots enables independent navigation through dynamic environments, while collaborative robots integrate adaptive path planning to safely coordinate movements with human workers.

Decentralized Control Systems

Decentralized control systems in autonomous robots enable independent operation through distributed decision-making, while collaborative robots rely on interconnected control architectures to synchronize tasks and enhance teamwork efficiency.

Autonomous Robots vs Collaborative Robots Infographic

njnir.com

njnir.com