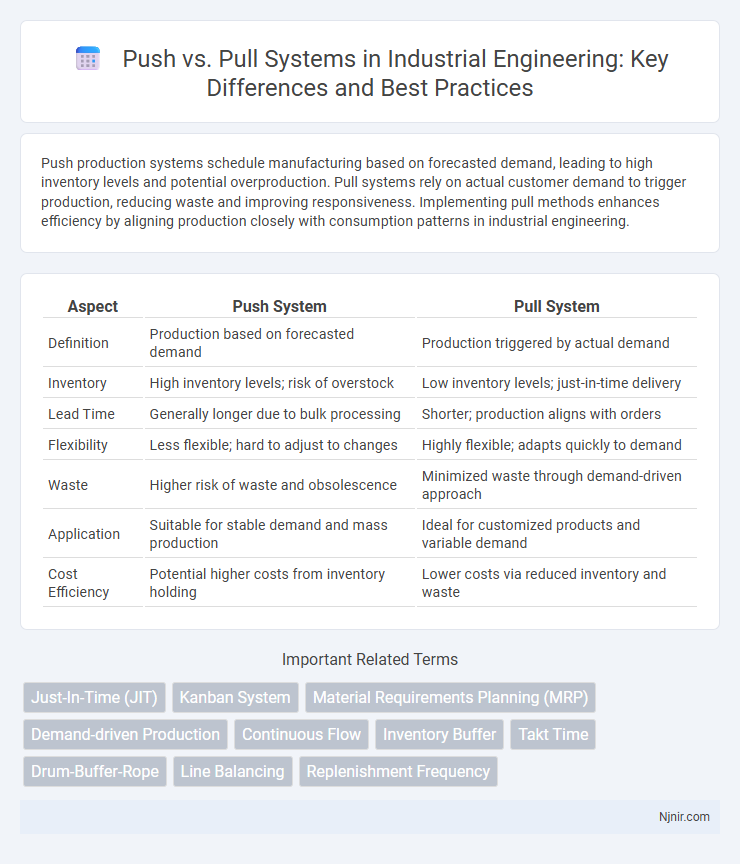

Push production systems schedule manufacturing based on forecasted demand, leading to high inventory levels and potential overproduction. Pull systems rely on actual customer demand to trigger production, reducing waste and improving responsiveness. Implementing pull methods enhances efficiency by aligning production closely with consumption patterns in industrial engineering.

Table of Comparison

| Aspect | Push System | Pull System |

|---|---|---|

| Definition | Production based on forecasted demand | Production triggered by actual demand |

| Inventory | High inventory levels; risk of overstock | Low inventory levels; just-in-time delivery |

| Lead Time | Generally longer due to bulk processing | Shorter; production aligns with orders |

| Flexibility | Less flexible; hard to adjust to changes | Highly flexible; adapts quickly to demand |

| Waste | Higher risk of waste and obsolescence | Minimized waste through demand-driven approach |

| Application | Suitable for stable demand and mass production | Ideal for customized products and variable demand |

| Cost Efficiency | Potential higher costs from inventory holding | Lower costs via reduced inventory and waste |

Introduction to Push and Pull Systems in Industrial Engineering

Push systems in industrial engineering rely on forecasted demand to schedule production, initiating processes based on predicted customer orders. Pull systems, conversely, trigger production only in response to actual demand, minimizing inventory levels and reducing waste. These contrasting approaches influence inventory control, lead times, and overall operational efficiency within manufacturing environments.

Defining Push Systems: Concepts and Applications

Push systems operate by forecasting demand and producing goods or services in advance, aiming to maintain inventory levels and meet anticipated customer needs. Common in manufacturing environments, these systems rely heavily on accurate demand predictions to minimize overproduction and stockouts. Applications include traditional assembly lines and supply chains where production schedules are predetermined and products are pushed through the distribution network.

Understanding Pull Systems: Principles and Methods

Pull systems operate by triggering production and inventory replenishment based on actual demand, minimizing overproduction and reducing waste. Key principles include just-in-time delivery, continuous flow, and Kanban signaling, which synchronize processes to customer consumption patterns. Methods such as demand-driven scheduling and visual management enhance responsiveness and ensure resources are allocated efficiently in lean manufacturing environments.

Key Differences Between Push and Pull Strategies

Push strategies involve proactively promoting products to customers through direct marketing, sales efforts, and distribution channels, aiming to create demand by pushing products onto consumers. Pull strategies focus on generating consumer demand by encouraging customers to seek out products through advertising, content marketing, and brand loyalty initiatives. The key difference lies in push driving products to consumers, while pull draws consumers to the products.

Advantages of Push Systems in Industrial Operations

Push systems in industrial operations enable proactive inventory management by forecasting demand and scheduling production accordingly, reducing idle time and maximizing resource utilization. They enhance workflow consistency and prevent stockouts by ensuring materials and products are available when needed. Efficient push strategies contribute to streamlined supply chain coordination, facilitating improved delivery reliability and customer satisfaction.

Benefits of Pull Systems in Modern Manufacturing

Pull systems in modern manufacturing significantly reduce inventory costs by producing goods only in response to actual customer demand, minimizing waste and overproduction. This approach enhances flexibility and responsiveness, allowing manufacturers to adapt quickly to market changes and customer preferences. Improved workflow efficiency and shorter lead times are direct benefits, leading to higher customer satisfaction and increased competitiveness in dynamic markets.

Common Challenges When Implementing Push vs Pull

Implementing push vs pull strategies often encounters challenges such as inventory misalignment, demand forecasting inaccuracies, and communication breakdowns across supply chain tiers. Push systems risk overproduction and excess stock, while pull systems may face delays and stockouts due to reliance on real-time demand signals. Effective integration of technology and data analytics is crucial to minimize these hurdles and achieve a balanced supply chain responsiveness.

Case Studies: Push vs Pull in Real-World Industries

Case studies in manufacturing reveal push systems excel in environments with predictable demand, such as automotive production lines where inventory is pre-planned to maximize efficiency. Conversely, pull systems are favored in fast fashion industries like Zara, enabling rapid response to consumer trends by producing goods only upon actual customer demand. Analysis in these real-world sectors highlights how pull strategies minimize waste and excess inventory, while push models optimize resource allocation when demand forecasts are reliable.

Choosing the Right System for Your Industrial Process

Selecting the appropriate push or pull system for your industrial process depends on production demand, inventory management, and workflow efficiency. Push systems drive production based on forecasted orders, ideal for high-volume, stable demand environments, while pull systems rely on actual consumption, minimizing waste and optimizing just-in-time inventory. Evaluating factors like lead times, variability in customer orders, and resource flexibility ensures alignment of the chosen system with operational goals and cost-effectiveness.

Future Trends: Evolving Push and Pull Approaches

Future trends in push vs pull strategies emphasize the integration of AI-driven personalization and real-time data analytics to enhance customer engagement and supply chain responsiveness. Advanced machine learning algorithms enable push systems to deliver highly targeted content while pull systems leverage demand forecasting to optimize inventory and reduce latency. The evolution of hybrid models blending proactive push notifications with reactive pull requests is set to redefine marketing and logistics efficiency.

Just-In-Time (JIT)

Just-In-Time (JIT) production uses a pull system that minimizes inventory by synchronizing manufacturing with customer demand, reducing waste and enhancing efficiency.

Kanban System

Kanban systems optimize workflow by visualizing tasks with pull-based control, allowing team members to start new work only when capacity is available, reducing bottlenecks and enhancing efficiency.

Material Requirements Planning (MRP)

Push-based Material Requirements Planning (MRP) schedules production and procurement according to forecasted demand, while pull-based MRP triggers manufacturing and inventory replenishment only after actual customer orders.

Demand-driven Production

Demand-driven production prioritizes pull systems where inventory replenishment is triggered by actual customer demand, reducing waste and enhancing responsiveness compared to push systems based on forecasted schedules.

Continuous Flow

Push systems schedule production based on forecasts causing inventory buildup, while Pull systems enable continuous flow by producing items in response to actual demand, minimizing waste and enhancing efficiency.

Inventory Buffer

Push inventory systems maintain larger inventory buffers to anticipate demand, while pull systems minimize buffers by producing based on actual consumption.

Takt Time

Push systems often lead to overproduction and increased inventory, whereas pull systems align production closely with Takt Time, ensuring workflow matches customer demand efficiently.

Drum-Buffer-Rope

Drum-Buffer-Rope optimizes production flow by using the drum to set the pace, the buffer to protect the critical constraint, and the rope to synchronize upstream processes, effectively combining pull system responsiveness with push system scheduling.

Line Balancing

Push production systems often lead to imbalanced workloads and increased bottlenecks, whereas pull production enables more efficient line balancing by synchronizing workstations with actual demand.

Replenishment Frequency

Push-based inventory systems schedule replenishment at fixed intervals regardless of demand, while pull-based systems trigger restocking dynamically based on real-time consumption rates.

Push vs Pull Infographic

njnir.com

njnir.com