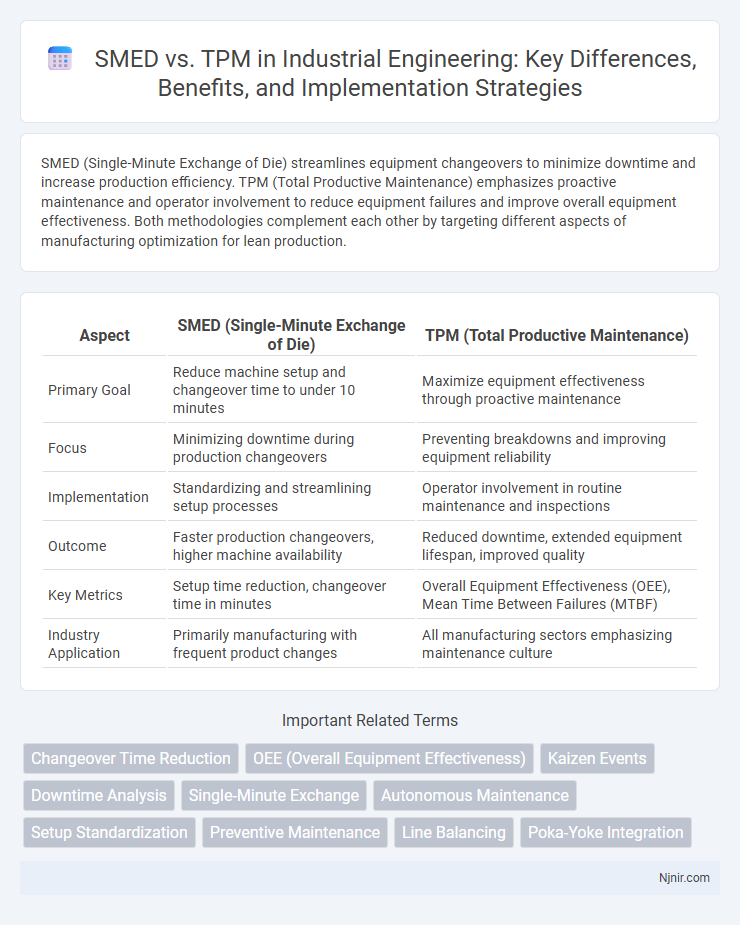

SMED (Single-Minute Exchange of Die) streamlines equipment changeovers to minimize downtime and increase production efficiency. TPM (Total Productive Maintenance) emphasizes proactive maintenance and operator involvement to reduce equipment failures and improve overall equipment effectiveness. Both methodologies complement each other by targeting different aspects of manufacturing optimization for lean production.

Table of Comparison

| Aspect | SMED (Single-Minute Exchange of Die) | TPM (Total Productive Maintenance) |

|---|---|---|

| Primary Goal | Reduce machine setup and changeover time to under 10 minutes | Maximize equipment effectiveness through proactive maintenance |

| Focus | Minimizing downtime during production changeovers | Preventing breakdowns and improving equipment reliability |

| Implementation | Standardizing and streamlining setup processes | Operator involvement in routine maintenance and inspections |

| Outcome | Faster production changeovers, higher machine availability | Reduced downtime, extended equipment lifespan, improved quality |

| Key Metrics | Setup time reduction, changeover time in minutes | Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF) |

| Industry Application | Primarily manufacturing with frequent product changes | All manufacturing sectors emphasizing maintenance culture |

Introduction to SMED and TPM in Industrial Engineering

Single-Minute Exchange of Dies (SMED) is a lean manufacturing methodology aimed at drastically reducing setup and changeover times in production processes to enhance operational efficiency and minimize downtime. Total Productive Maintenance (TPM) focuses on comprehensive equipment maintenance involving all employees to maximize machine availability, reduce breakdowns, and improve overall equipment effectiveness (OEE). Both SMED and TPM are critical industrial engineering strategies that streamline production workflows, boost productivity, and support continuous improvement within manufacturing environments.

Key Principles of SMED (Single-Minute Exchange of Dies)

SMED (Single-Minute Exchange of Dies) centers on reducing equipment setup times to less than 10 minutes by separating internal and external setup activities and converting as many internal steps to external ones as possible. This method emphasizes standardization, quick-release mechanisms, and streamlined workflows to facilitate rapid changeovers. By minimizing downtime, SMED enhances manufacturing flexibility and supports TPM (Total Productive Maintenance) initiatives aimed at maximizing equipment efficiency.

Core Concepts of TPM (Total Productive Maintenance)

Total Productive Maintenance (TPM) centers on maximizing equipment effectiveness through proactive and preventive maintenance involving operators in routine care to minimize breakdowns and downtime. It emphasizes Autonomous Maintenance, Planned Maintenance, and Continuous Improvement to enhance overall equipment efficiency (OEE). TPM integrates cross-functional teams to support equipment reliability, safety, and quality, driving productivity and reducing waste across manufacturing processes.

Objectives: SMED vs TPM

SMED (Single-Minute Exchange of Dies) focuses on reducing setup and changeover times to enhance production efficiency and minimize downtime. TPM (Total Productive Maintenance) aims to maximize overall equipment effectiveness by involving all employees in proactive maintenance to prevent breakdowns and defects. Both methodologies improve manufacturing productivity, but SMED targets quick transitions between processes while TPM emphasizes sustained equipment reliability.

Implementation Steps: SMED vs TPM

SMED implementation steps focus on reducing changeover times through separating internal and external setup activities, streamlining tool organization, and standardizing quick-release mechanisms to enable rapid transitions. TPM implementation emphasizes establishing autonomous maintenance routines, scheduling planned maintenance, and continuous improvement involving all operators to maximize equipment availability and reduce breakdowns. Both methods require structured training and cross-functional teams but differ as SMED targets setup efficiency while TPM aims for overall equipment effectiveness.

Impact on Production Efficiency

SMED (Single-Minute Exchange of Dies) drastically reduces equipment setup times, enabling faster changeovers that increase machine availability and minimize production downtime. TPM (Total Productive Maintenance) enhances equipment reliability by involving operators in routine maintenance, reducing breakdowns and defects to ensure smooth, continuous operations. Together, SMED and TPM synergize to maximize production efficiency by balancing quick changeovers with ongoing asset optimization.

Downtime Reduction: SMED and TPM Approaches

SMED (Single-Minute Exchange of Dies) drastically reduces equipment downtime by streamlining changeover processes to under 10 minutes, enhancing production flexibility and minimizing lost time. TPM (Total Productive Maintenance) targets downtime reduction through proactive maintenance, operator involvement, and continuous improvement, aiming to prevent breakdowns and improve overall equipment effectiveness (OEE). Both methodologies complement each other by addressing downtime from changeover efficiency (SMED) and maintenance reliability (TPM), significantly boosting production uptime.

Workforce Involvement in SMED and TPM

SMED (Single-Minute Exchange of Dies) emphasizes rapid changeovers through workforce training and active operator participation to minimize downtime and improve machine availability. TPM (Total Productive Maintenance) engages employees at all levels in proactive maintenance tasks, fostering ownership and collaboration to reduce equipment failures and enhance productivity. Both methodologies rely on a committed workforce, but SMED focuses more on quick tooling changes while TPM centers on comprehensive equipment care and continuous improvement.

Challenges and Solutions in SMED vs TPM

SMED (Single-Minute Exchange of Dies) faces challenges such as reducing setup times without compromising quality, requiring precise coordination and employee training to streamline machine changeovers efficiently. TPM (Total Productive Maintenance) encounters difficulties in maintaining consistent equipment reliability and engaging all employees in proactive maintenance activities to prevent breakdowns. Solutions for SMED emphasize standardized procedures, cross-functional team collaboration, and continuous improvement, while TPM benefits from autonomous maintenance, scheduled inspections, and comprehensive operator involvement to enhance overall equipment effectiveness.

Integrating SMED and TPM for Lean Manufacturing

Integrating SMED (Single-Minute Exchange of Dies) with TPM (Total Productive Maintenance) enhances Lean Manufacturing by minimizing downtime and maximizing equipment efficiency. SMED accelerates setup times, enabling quicker transitions between production runs, while TPM ensures machines operate reliably through proactive maintenance practices. This synergy reduces waste, increases productivity, and supports continuous improvement within manufacturing systems.

Changeover Time Reduction

SMED reduces changeover time by streamlining setup steps to under 10 minutes, while TPM enhances overall equipment effectiveness by preventing breakdowns and maintaining machinery for faster, more reliable changeovers.

OEE (Overall Equipment Effectiveness)

Implementing SMED reduces changeover time, enhancing OEE by increasing equipment availability, while TPM improves OEE through proactive maintenance that boosts equipment performance and quality.

Kaizen Events

Kaizen Events in SMED streamline changeover times to enhance equipment efficiency, while in TPM they drive continuous improvement through collaborative maintenance and problem-solving activities.

Downtime Analysis

SMED reduces equipment downtime by streamlining changeover processes, while TPM minimizes downtime through proactive maintenance and operator involvement.

Single-Minute Exchange

Single-Minute Exchange of Die (SMED) significantly reduces machine setup time by streamlining changeover processes, whereas Total Productive Maintenance (TPM) focuses broadly on maximizing overall equipment effectiveness through preventive maintenance and operator involvement.

Autonomous Maintenance

Autonomous Maintenance in TPM empowers operators to perform routine maintenance tasks, significantly reducing setup times and enhancing SMED efficiency.

Setup Standardization

SMED enhances Setup Standardization by drastically reducing equipment changeover times, while TPM ensures consistent execution through preventive maintenance and operator involvement.

Preventive Maintenance

SMED accelerates changeover times reducing downtime, while TPM emphasizes preventive maintenance to enhance equipment reliability and minimize unplanned breakdowns.

Line Balancing

SMED reduces changeover time to improve line balancing efficiency by minimizing downtime, while TPM enhances equipment reliability to maintain consistent production flow.

Poka-Yoke Integration

Integrating Poka-Yoke with SMED enhances rapid changeover efficiency by error-proofing setup steps, while embedding it in TPM strengthens equipment reliability through systematic mistake prevention during maintenance.

SMED vs TPM Infographic

njnir.com

njnir.com