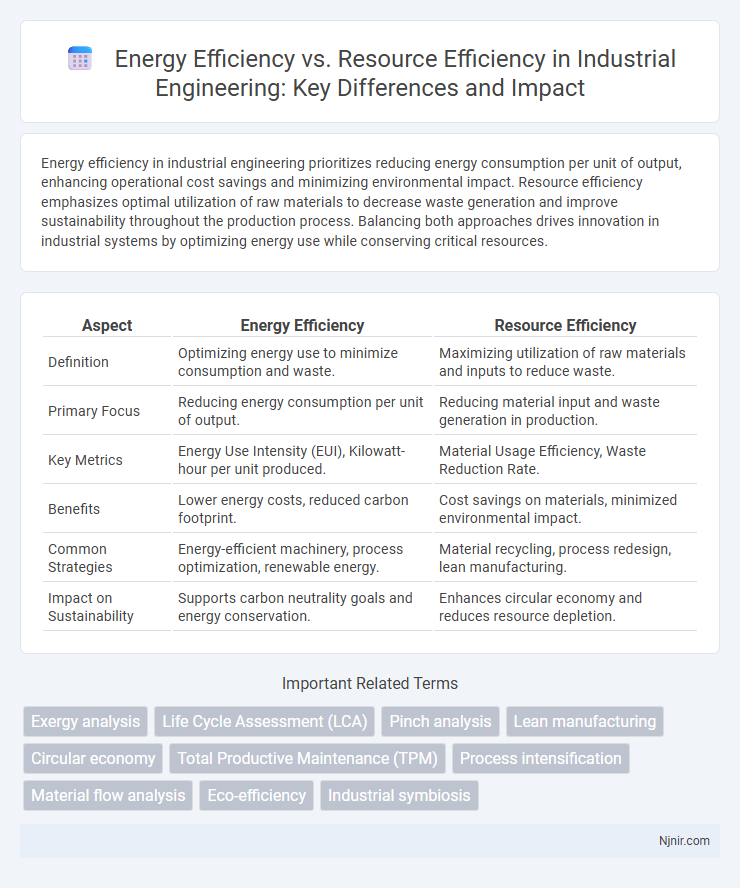

Energy efficiency in industrial engineering prioritizes reducing energy consumption per unit of output, enhancing operational cost savings and minimizing environmental impact. Resource efficiency emphasizes optimal utilization of raw materials to decrease waste generation and improve sustainability throughout the production process. Balancing both approaches drives innovation in industrial systems by optimizing energy use while conserving critical resources.

Table of Comparison

| Aspect | Energy Efficiency | Resource Efficiency |

|---|---|---|

| Definition | Optimizing energy use to minimize consumption and waste. | Maximizing utilization of raw materials and inputs to reduce waste. |

| Primary Focus | Reducing energy consumption per unit of output. | Reducing material input and waste generation in production. |

| Key Metrics | Energy Use Intensity (EUI), Kilowatt-hour per unit produced. | Material Usage Efficiency, Waste Reduction Rate. |

| Benefits | Lower energy costs, reduced carbon footprint. | Cost savings on materials, minimized environmental impact. |

| Common Strategies | Energy-efficient machinery, process optimization, renewable energy. | Material recycling, process redesign, lean manufacturing. |

| Impact on Sustainability | Supports carbon neutrality goals and energy conservation. | Enhances circular economy and reduces resource depletion. |

Understanding Energy Efficiency in Industrial Engineering

Energy efficiency in industrial engineering focuses on minimizing energy consumption while maintaining or improving production output, which reduces operational costs and carbon emissions. It involves optimizing processes, equipment, and systems to use less energy for the same level of production, often through advanced monitoring and control technologies. Resource efficiency, however, encompasses a broader scope by aiming to maximize the use of all materials and inputs, reducing waste and environmental impact beyond just energy savings.

Defining Resource Efficiency in Industrial Processes

Resource efficiency in industrial processes refers to the strategic use of materials, energy, water, and other inputs to maximize output while minimizing waste and environmental impact. It emphasizes optimizing raw material consumption and recycling within production cycles to reduce costs and resource depletion. By integrating advanced technologies and process innovations, industries can achieve sustainable growth and regulatory compliance through enhanced resource utilization.

Key Differences Between Energy Efficiency and Resource Efficiency

Energy efficiency focuses on reducing the amount of energy required to perform a task, while resource efficiency prioritizes minimizing the overall consumption of raw materials, water, and waste generation throughout production and consumption processes. Key differences include energy efficiency targeting improvements in devices, systems, and processes to use less energy for the same output, whereas resource efficiency encompasses a broader scope by optimizing material use, recycling, and sustainable resource management. Energy efficiency primarily reduces greenhouse gas emissions and operational costs, while resource efficiency enhances sustainability by reducing environmental impact and preserving natural ecosystems.

Importance of Energy Efficiency for Modern Industries

Energy efficiency reduces operational costs and minimizes carbon footprints in modern industries by optimizing energy consumption in manufacturing processes and equipment. Implementing advanced technologies such as smart grids, energy-efficient motors, and LED lighting enhances productivity while lowering greenhouse gas emissions. Prioritizing energy efficiency supports sustainable development goals, drives innovation, and improves competitiveness in global markets.

Benefits of Resource Efficiency in Manufacturing

Resource efficiency in manufacturing significantly reduces material waste and lowers production costs by optimizing the use of raw inputs and minimizing excess consumption. This approach enhances sustainability by decreasing environmental impact, conserving finite resources, and supporting circular economy principles. Improved resource efficiency also boosts operational resilience, enabling manufacturers to adapt to supply chain disruptions and volatile market prices more effectively.

Comparative Analysis: Energy Consumption vs. Material Utilization

Energy efficiency emphasizes reducing energy consumption by optimizing processes and technologies, directly lowering operational costs and environmental impact. Resource efficiency prioritizes minimizing material utilization and waste generation, aiming for sustainable use of raw materials and circular economy principles. Comparative analysis reveals that energy efficiency often targets short-term cost savings through improved energy use, whereas resource efficiency addresses long-term sustainability by conserving raw materials and reducing ecological footprint.

Measuring and Monitoring Efficiency: Metrics and Tools

Energy efficiency focuses on metrics like kilowatt-hour per unit output and power usage effectiveness (PUE) to measure energy consumption relative to performance. Resource efficiency involves tracking indicators such as material input per product yield and water usage ratio to monitor the sustainable use of raw materials. Tools like energy management systems (EMS) and lifecycle assessment (LCA) software enable precise monitoring and optimization of both energy and resource efficiencies across operations.

Challenges in Balancing Energy and Resource Efficiency

Balancing energy efficiency and resource efficiency presents challenges such as conflicting goals where optimizing energy use may increase material consumption or vice versa. Industries face difficulty in integrating technologies that reduce energy demand without escalating resource depletion or waste generation. Moreover, lack of comprehensive metrics complicates decision-making, hindering effective assessment of trade-offs between minimizing energy consumption and conserving raw materials.

Integrating Sustainable Practices in Industrial Engineering

Energy efficiency reduces power consumption by optimizing processes and equipment, leading to lower operational costs and environmental impact. Resource efficiency emphasizes minimizing raw material use and waste generation throughout the production cycle, crucial for sustainable resource management. Integrating both strategies in industrial engineering enhances overall sustainability, promotes circular economy principles, and drives long-term competitive advantage.

Future Trends: Towards Synergistic Efficiency in Industry

Future trends in industrial efficiency emphasize the integration of energy efficiency and resource efficiency to achieve synergistic benefits. Advanced technologies like AI-driven process optimization and circular economy models enhance both energy consumption and material usage simultaneously. This holistic approach drives sustainable manufacturing by minimizing waste and reducing carbon footprints throughout the production lifecycle.

Exergy analysis

Exergy analysis quantifies the true useful energy potential lost in processes, making it a critical tool to compare energy efficiency and resource efficiency by revealing where resource degradation limits sustainable use beyond mere energy consumption metrics.

Life Cycle Assessment (LCA)

Energy efficiency reduces energy consumption during a product's use phase, while resource efficiency minimizes material inputs and waste across the entire Life Cycle Assessment (LCA) from raw material extraction to disposal.

Pinch analysis

Pinch analysis optimizes energy efficiency by identifying minimum energy requirements and heat recovery opportunities while resource efficiency focuses on minimizing raw material usage and waste generation through integrated process design.

Lean manufacturing

Lean manufacturing enhances energy efficiency by minimizing waste and streamlining processes while improving resource efficiency through optimized material utilization and reduced inventory.

Circular economy

Energy efficiency in circular economy minimizes energy consumption during production, while resource efficiency prioritizes maximal reuse and recycling of materials to reduce waste and environmental impact.

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) enhances energy and resource efficiency by minimizing equipment downtime, optimizing asset utilization, and reducing waste throughout production processes.

Process intensification

Process intensification enhances energy efficiency by minimizing energy consumption and resource efficiency by reducing raw material use and waste generation through streamlined industrial operations.

Material flow analysis

Material flow analysis reveals that resource efficiency optimizes the sustainable use of raw materials throughout production cycles, while energy efficiency primarily targets reducing energy consumption within those processes.

Eco-efficiency

Eco-efficiency maximizes both energy and resource efficiency by minimizing environmental impact while optimizing economic value throughout production and consumption processes.

Industrial symbiosis

Industrial symbiosis enhances energy efficiency and resource efficiency by enabling waste heat and materials from one process to be input for another, significantly reducing overall industrial resource consumption and greenhouse gas emissions.

Energy efficiency vs Resource efficiency Infographic

njnir.com

njnir.com