Condition-based monitoring utilizes real-time data and sensor technologies to assess equipment health, enabling timely interventions before failures occur. Reliability-centered maintenance prioritizes maintenance activities based on the criticality and failure consequences of assets, optimizing resource allocation and extending equipment life. Combining both approaches enhances operational efficiency by preventing unexpected downtime and reducing maintenance costs.

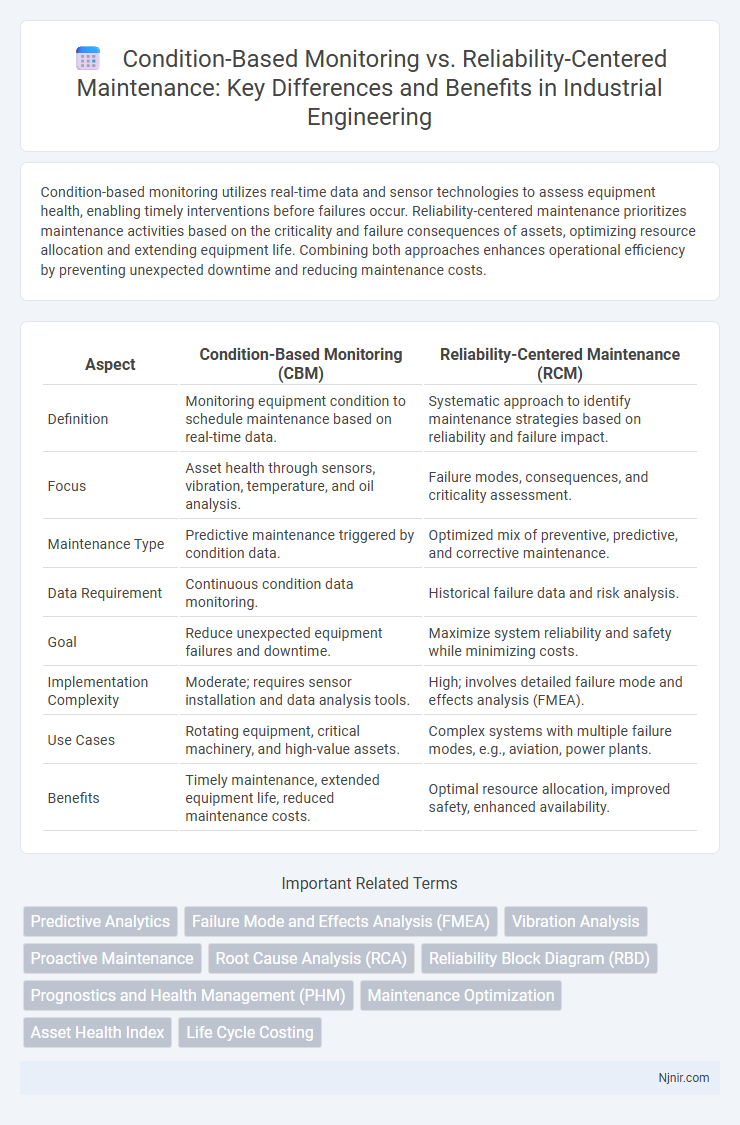

Table of Comparison

| Aspect | Condition-Based Monitoring (CBM) | Reliability-Centered Maintenance (RCM) |

|---|---|---|

| Definition | Monitoring equipment condition to schedule maintenance based on real-time data. | Systematic approach to identify maintenance strategies based on reliability and failure impact. |

| Focus | Asset health through sensors, vibration, temperature, and oil analysis. | Failure modes, consequences, and criticality assessment. |

| Maintenance Type | Predictive maintenance triggered by condition data. | Optimized mix of preventive, predictive, and corrective maintenance. |

| Data Requirement | Continuous condition data monitoring. | Historical failure data and risk analysis. |

| Goal | Reduce unexpected equipment failures and downtime. | Maximize system reliability and safety while minimizing costs. |

| Implementation Complexity | Moderate; requires sensor installation and data analysis tools. | High; involves detailed failure mode and effects analysis (FMEA). |

| Use Cases | Rotating equipment, critical machinery, and high-value assets. | Complex systems with multiple failure modes, e.g., aviation, power plants. |

| Benefits | Timely maintenance, extended equipment life, reduced maintenance costs. | Optimal resource allocation, improved safety, enhanced availability. |

Introduction to Condition-Based Monitoring and Reliability-Centered Maintenance

Condition-Based Monitoring (CBM) involves continuous or periodic measurement of equipment parameters such as vibration, temperature, and oil analysis to detect anomalies before failures occur. Reliability-Centered Maintenance (RCM) prioritizes maintenance activities based on the criticality and impact of potential equipment failures, optimizing resources to ensure system reliability. Both CBM and RCM aim to enhance operational efficiency and reduce maintenance costs by applying targeted strategies based on equipment condition and failure risk.

Key Principles of Condition-Based Monitoring

Condition-based monitoring relies on real-time data from sensors and diagnostic tools to assess equipment health and predict failures, minimizing unnecessary maintenance. It emphasizes continuous measurement of parameters such as vibration, temperature, and pressure to detect deviations from normal operating conditions. This proactive approach contrasts with reliability-centered maintenance, which prioritizes failure consequences and maintenance strategies based on risk and criticality analysis.

Core Concepts of Reliability-Centered Maintenance

Reliability-centered maintenance (RCM) prioritizes maintaining system functions by identifying critical failure modes and selecting appropriate maintenance tasks to mitigate risks, focusing on optimizing asset reliability and safety. Condition-based monitoring (CBM) relies on real-time data from sensors to detect equipment deterioration and trigger maintenance only when necessary, reducing unnecessary interventions. The core concept of RCM lies in systematically assessing failure consequences and integrating preventive, predictive, and corrective maintenance strategies to ensure mission-critical asset performance.

Comparison: Objectives and Approaches

Condition-based monitoring (CBM) focuses on real-time data collection and analysis to detect equipment degradation and predict failures, aiming to perform maintenance only when necessary. Reliability-centered maintenance (RCM) prioritizes identifying critical assets and failure modes to develop tailored maintenance strategies that optimize reliability and safety. While CBM relies heavily on sensor data and diagnostic techniques, RCM uses a systematic decision-making process incorporating both failure consequences and maintenance policies.

Data Requirements and Analysis Techniques

Condition-based monitoring relies heavily on real-time sensor data such as vibration, temperature, and pressure to detect anomalies, requiring continuous data acquisition and advanced analytics like signal processing and trend analysis. Reliability-centered maintenance focuses on failure modes and criticality, utilizing historical failure data and risk assessments to prioritize maintenance activities, often employing techniques like failure mode and effects analysis (FMEA) and probabilistic modeling. Both approaches demand robust data management systems, but condition-based monitoring emphasizes dynamic data streams whereas reliability-centered maintenance depends more on structured historical and qualitative data for decision-making.

Implementation Challenges in Industrial Settings

Condition-based monitoring (CBM) faces implementation challenges such as the high initial cost of sensor installation, integration with existing systems, and the need for skilled personnel to interpret data accurately in industrial settings. Reliability-centered maintenance (RCM) requires comprehensive failure mode analysis and organizational commitment, which can be resource-intensive and difficult to sustain over time due to complex machinery and varying operational conditions. Both strategies demand robust data management systems and alignment with maintenance culture to overcome resistance and ensure effective deployment.

Cost-Benefit Analysis: CBM vs. RCM

Condition-based monitoring (CBM) offers real-time data collection that enables timely maintenance actions, significantly reducing unplanned downtime and lowering maintenance costs compared to traditional methods. Reliability-centered maintenance (RCM) provides a structured approach focused on identifying critical assets and failure modes, optimizing maintenance tasks to enhance overall system reliability but may require higher initial analysis and implementation costs. Cost-benefit analysis typically shows CBM delivers quicker ROI through reduced labor and material expenses, while RCM offers long-term savings by preventing catastrophic failures and extending asset life.

Case Studies and Real-World Applications

Case studies reveal that Condition-Based Monitoring (CBM) enhances predictive capabilities by utilizing real-time sensor data to detect equipment anomalies sooner, as seen in industries like manufacturing and aerospace where vibration analysis and thermal imaging optimize maintenance schedules. Reliability-Centered Maintenance (RCM) frameworks prioritize critical asset functions and failure modes, demonstrated in aviation and utilities sectors to systematically reduce downtime and extend asset life by integrating CBM data with safety and operational objectives. Real-world applications highlight that combining CBM's continuous data-driven insights with RCM's structured decision-making optimizes maintenance strategies, improving reliability and cost-efficiency across various complex industrial environments.

Integration with Industry 4.0 Technologies

Condition-based monitoring leverages real-time sensor data and IoT connectivity to detect equipment anomalies, enabling immediate maintenance actions guided by Industry 4.0 analytics platforms. Reliability-centered maintenance integrates predictive algorithms and digital twins within Industry 4.0 ecosystems to prioritize maintenance tasks based on risk and criticality, optimizing asset performance and lifespan. Both strategies utilize cloud computing, AI, and big data to enhance decision-making but differ in scope, with condition-based monitoring focusing on current asset health and reliability-centered maintenance emphasizing long-term reliability planning.

Future Trends in Industrial Maintenance Strategies

Future trends in industrial maintenance strategies highlight the growing integration of Condition-Based Monitoring (CBM) with Reliability-Centered Maintenance (RCM) to leverage predictive analytics and real-time data for enhanced asset management. Advances in IoT sensors and AI-driven diagnostics enable more precise failure prediction, reducing downtime and maintenance costs through proactive interventions. The convergence of CBM and RCM fosters adaptive maintenance scheduling, optimizing reliability and extending equipment lifespan in smart manufacturing environments.

Predictive Analytics

Condition-based monitoring leverages real-time predictive analytics to detect equipment anomalies early, while reliability-centered maintenance uses predictive data to prioritize maintenance strategies based on risk and failure consequences.

Failure Mode and Effects Analysis (FMEA)

Condition-based monitoring enhances Reliability-centered maintenance by providing real-time asset data that improves the accuracy of Failure Mode and Effects Analysis (FMEA) in identifying and mitigating potential failure modes.

Vibration Analysis

Condition-based monitoring utilizes vibration analysis to detect machinery faults in real-time, while reliability-centered maintenance integrates vibration data to prioritize maintenance actions based on asset criticality and failure modes.

Proactive Maintenance

Condition-based monitoring enhances proactive maintenance by continuously assessing equipment health to prevent failures, while reliability-centered maintenance systematically prioritizes maintenance tasks based on risk and criticality to ensure optimal asset performance.

Root Cause Analysis (RCA)

Condition-based monitoring enhances Root Cause Analysis (RCA) by providing real-time data for precise fault detection, while Reliability-centered maintenance (RCM) integrates RCA to prioritize maintenance tasks based on failure modes and operational risks.

Reliability Block Diagram (RBD)

Reliability Block Diagram (RBD) enhances Reliability-centered maintenance by visually modeling system reliability, whereas Condition-based monitoring focuses on real-time data to predict failures.

Prognostics and Health Management (PHM)

Condition-based monitoring enables real-time data collection for Prognostics and Health Management (PHM), while Reliability-centered maintenance prioritizes maintenance strategies based on system failure probabilities to optimize PHM outcomes.

Maintenance Optimization

Condition-based monitoring enhances maintenance optimization by providing real-time equipment data to predict failures, while reliability-centered maintenance focuses on systematically prioritizing maintenance tasks based on risk and failure modes to improve overall asset reliability.

Asset Health Index

Condition-based monitoring enhances the Asset Health Index by providing real-time data for targeted maintenance, whereas Reliability-centered maintenance improves it through systematic analysis of failure modes and critical asset functions.

Life Cycle Costing

Condition-based monitoring reduces Life Cycle Costing by enabling targeted maintenance actions, whereas Reliability-centered maintenance optimizes Life Cycle Costing through strategic planning based on asset criticality and failure modes.

Condition-based monitoring vs Reliability-centered maintenance Infographic

njnir.com

njnir.com