Industry 4.0 integrates cyber-physical systems, IoT, and big data analytics to create smart factories with enhanced automation and real-time decision-making capabilities, surpassing the digital and automation advances of Industry 3.0. Unlike Industry 3.0, which primarily focused on electrification and computer-based automation, Industry 4.0 emphasizes interconnectivity, decentralized intelligence, and seamless communication across supply chains. This transformation drives higher efficiency, flexibility, and customization in manufacturing processes.

Table of Comparison

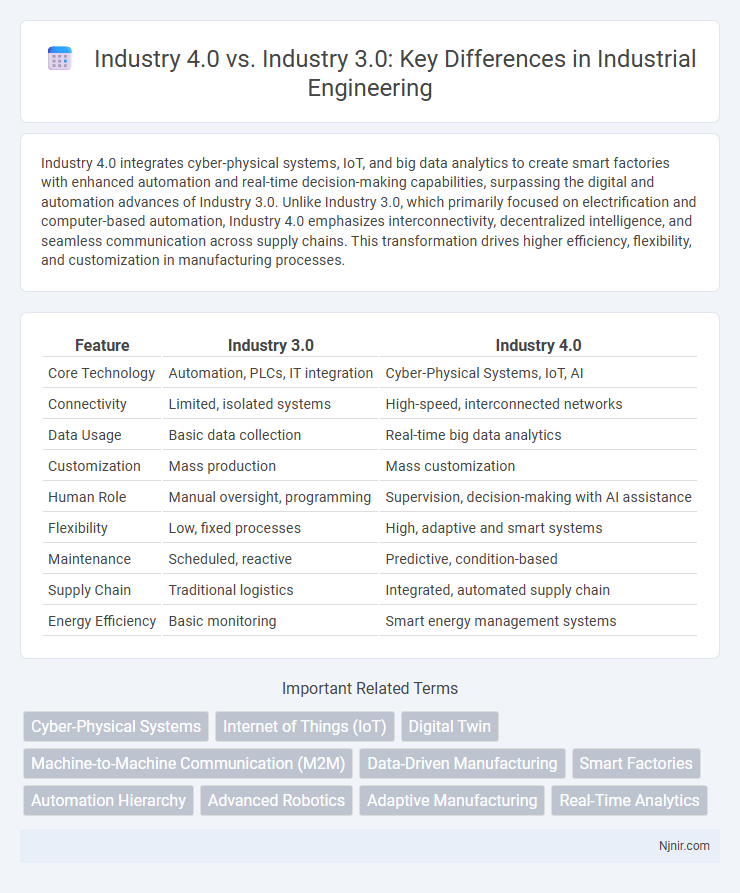

| Feature | Industry 3.0 | Industry 4.0 |

|---|---|---|

| Core Technology | Automation, PLCs, IT integration | Cyber-Physical Systems, IoT, AI |

| Connectivity | Limited, isolated systems | High-speed, interconnected networks |

| Data Usage | Basic data collection | Real-time big data analytics |

| Customization | Mass production | Mass customization |

| Human Role | Manual oversight, programming | Supervision, decision-making with AI assistance |

| Flexibility | Low, fixed processes | High, adaptive and smart systems |

| Maintenance | Scheduled, reactive | Predictive, condition-based |

| Supply Chain | Traditional logistics | Integrated, automated supply chain |

| Energy Efficiency | Basic monitoring | Smart energy management systems |

Introduction to Industry 3.0 and Industry 4.0

Industry 3.0, known as the Digital Revolution, emphasized automation through electronics and IT to create smart machines and improve manufacturing efficiency. Industry 4.0 integrates cyber-physical systems, the Internet of Things (IoT), and artificial intelligence to enable real-time data exchange, smart factories, and autonomous decision-making. This transformation drives enhanced production flexibility, predictive maintenance, and connected supply chains, marking a significant evolution from the computer-based automation of Industry 3.0.

Core Technologies of Industry 3.0

Industry 3.0, also known as the Third Industrial Revolution, primarily revolves around automation through the introduction of computers, programmable logic controllers (PLCs), and robotics in manufacturing processes. Core technologies of Industry 3.0 include digital control systems, microprocessors, and information technology integration that enabled early factory automation and improved production efficiency. These advancements contrast with Industry 4.0's emphasis on cyber-physical systems, IoT, and advanced data analytics for smart, interconnected manufacturing.

Foundations of Industry 4.0

Industry 4.0 revolutionizes manufacturing through cyber-physical systems, IoT, and real-time data analytics, building on the automation and electronics foundation of Industry 3.0. The integration of smart factories with decentralized decision-making enables increased efficiency, flexibility, and predictive maintenance. Core technologies like AI, cloud computing, and advanced robotics establish Industry 4.0 as a foundation for the future of intelligent production systems.

Key Differences Between Industry 3.0 and 4.0

Industry 3.0, known as the Third Industrial Revolution, centered on automation using computers and programmable logic controllers (PLCs) to improve manufacturing efficiency. Industry 4.0 builds on this foundation by integrating cyber-physical systems, the Internet of Things (IoT), big data analytics, and artificial intelligence (AI) to create smart factories with real-time data exchange and autonomous decision-making. The key differences include Industry 4.0's emphasis on connectivity, decentralized control, and enhanced human-machine collaboration, which drive increased productivity, flexibility, and customization compared to the more isolated and manual automation of Industry 3.0.

Impact on Production and Manufacturing Processes

Industry 4.0 revolutionizes production and manufacturing processes through the integration of cyber-physical systems, IoT connectivity, and advanced data analytics, enabling real-time monitoring, predictive maintenance, and smart automation. Unlike Industry 3.0, which relied heavily on computer automation and robotics with limited data processing capabilities, Industry 4.0 fosters decentralized decision-making and adaptive manufacturing systems that enhance flexibility and efficiency. This shift results in reduced downtime, improved product customization, and optimized supply chain operations, driving higher productivity and cost savings.

Automation: From Mechanization to Smart Systems

Industry 4.0 marks a significant evolution from Industry 3.0 by integrating advanced automation technologies such as IoT, AI, and cyber-physical systems to create smart factories with real-time data exchange and autonomous decision-making. While Industry 3.0 focused on mechanization and basic automation through programmable logic controllers (PLCs) and robotics, Industry 4.0 emphasizes connectivity, machine learning, and predictive maintenance for enhanced efficiency and flexibility. This shift enables dynamic production processes, improved supply chain management, and reduced human intervention in manufacturing.

Data Integration and Real-Time Analytics

Industry 4.0 revolutionizes manufacturing by integrating advanced data integration techniques and real-time analytics, enabling seamless communication between IoT devices, sensors, and cloud platforms. Unlike Industry 3.0, which primarily relied on isolated automation and manual data collection, Industry 4.0 leverages big data and AI to optimize operations, predict maintenance needs, and improve decision-making efficiency. This transformation enhances production flexibility, reduces downtime, and drives smart factory innovation through continuous data flow and instant analytical insights.

Workforce Skills: Evolving Roles and Competencies

Industry 4.0 demands advanced digital literacy, data analysis, and cyber-physical system management, transforming workforce skills beyond the mechanical and basic automation proficiency of Industry 3.0. Workers in Industry 4.0 must develop competencies in artificial intelligence, IoT integration, and real-time decision-making, reflecting a shift towards more interdisciplinary and tech-centric roles. This evolution emphasizes continuous learning and adaptability to leverage smart technologies and enhance productivity in connected manufacturing environments.

Challenges and Barriers in Adopting Industry 4.0

Industry 4.0 introduces advanced automation, IoT integration, and real-time data analytics, posing significant challenges such as cybersecurity risks, high implementation costs, and the need for skilled workforce transformation compared to Industry 3.0. Legacy systems and interoperability issues create barriers in adopting Industry 4.0 technologies, complicating seamless integration across manufacturing processes. Resistance to change and lack of standardized protocols further hinder efficient deployment and scalability of Industry 4.0 solutions in traditional industrial environments.

Future Outlook for Industrial Engineering

Industry 4.0 integrates advanced technologies such as artificial intelligence, the Internet of Things (IoT), and cyber-physical systems to enhance automation, real-time data analytics, and smart manufacturing processes, surpassing the primarily automation-focused Industry 3.0. The future outlook for industrial engineering involves adopting digital twins, predictive maintenance, and machine learning to optimize production efficiency, reduce downtime, and enable more flexible manufacturing systems. Emphasizing human-machine collaboration and sustainable practices will further drive innovation and competitiveness in the evolving industrial landscape.

Cyber-Physical Systems

Industry 4.0 integrates advanced Cyber-Physical Systems enabling real-time data exchange and automation, whereas Industry 3.0 primarily relies on digital automation without deeply interconnected physical and computational processes.

Internet of Things (IoT)

Industry 4.0 leverages Internet of Things (IoT) technology for real-time data exchange and automation, unlike Industry 3.0's reliance on computerized automation without extensive interconnectivity.

Digital Twin

Industry 4.0 integrates Digital Twin technology to create real-time virtual replicas of physical assets, enabling predictive maintenance and enhanced operational efficiency that Industry 3.0 automation lacks.

Machine-to-Machine Communication (M2M)

Industry 4.0 enhances Machine-to-Machine Communication (M2M) through real-time data exchange and decentralized decision-making, unlike Industry 3.0 which relies on isolated automation systems with limited connectivity.

Data-Driven Manufacturing

Industry 4.0 revolutionizes manufacturing by integrating IoT, AI, and big data analytics to enable real-time, data-driven decision-making, surpassing Industry 3.0's automation and computerization capabilities.

Smart Factories

Industry 4.0 transforms traditional Industry 3.0 factories by integrating cyber-physical systems, IoT, and real-time data analytics to enable fully automated, self-optimizing smart factories.

Automation Hierarchy

Industry 4.0 advances the Automation Hierarchy by integrating cyber-physical systems and IoT for real-time data exchange, whereas Industry 3.0 primarily relies on standalone programmable logic controllers and basic automation layers.

Advanced Robotics

Advanced robotics in Industry 4.0 enable real-time data integration and autonomous decision-making, surpassing the programmable automation and fixed production lines characteristic of Industry 3.0.

Adaptive Manufacturing

Industry 4.0 revolutionizes adaptive manufacturing by integrating IoT, AI, and real-time data analytics for autonomous decision-making, whereas Industry 3.0 relied primarily on computer automation with limited flexibility and real-time responsiveness.

Real-Time Analytics

Industry 4.0 leverages real-time analytics through IoT-enabled sensors and AI-driven data processing, enabling instant decision-making and predictive maintenance, whereas Industry 3.0 relies primarily on automated systems with limited data integration and delayed analytics.

Industry 4.0 vs Industry 3.0 Infographic

njnir.com

njnir.com