FMEA (Failure Modes and Effects Analysis) systematically identifies potential failure modes within a process or product, prioritizing them based on their impact to implement preventive measures. Fault Tree Analysis (FTA) uses a top-down approach to analyze the root causes of system failures by mapping logical relationships between faults through a tree diagram. Both methods complement each other in industrial engineering by providing comprehensive risk assessment tools aimed at improving reliability and safety.

Table of Comparison

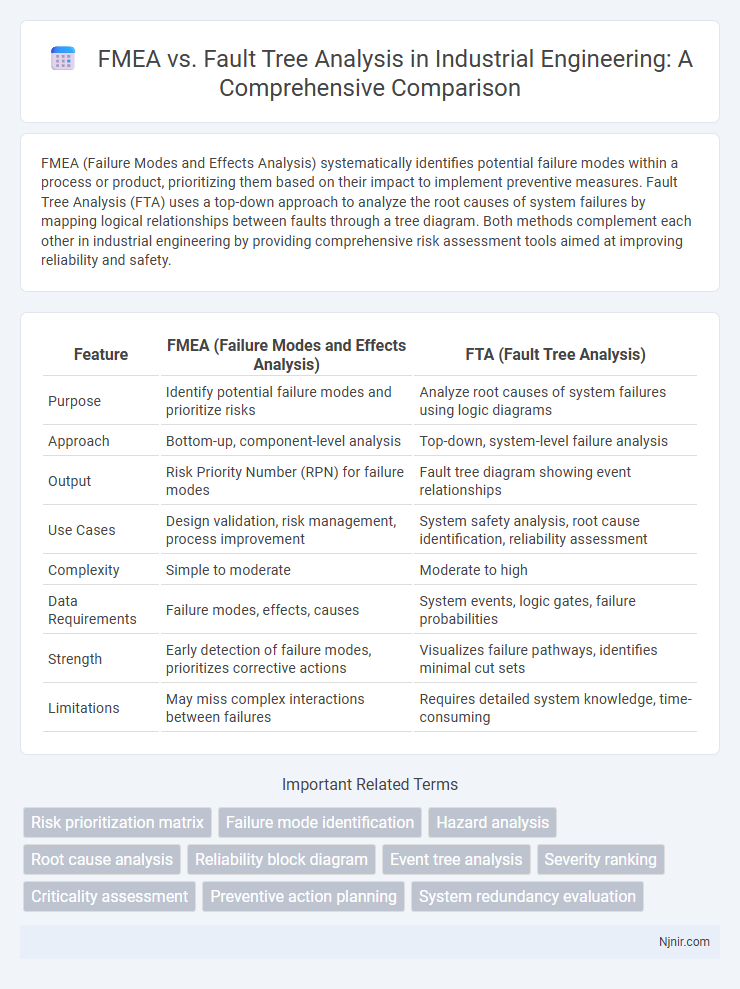

| Feature | FMEA (Failure Modes and Effects Analysis) | FTA (Fault Tree Analysis) |

|---|---|---|

| Purpose | Identify potential failure modes and prioritize risks | Analyze root causes of system failures using logic diagrams |

| Approach | Bottom-up, component-level analysis | Top-down, system-level failure analysis |

| Output | Risk Priority Number (RPN) for failure modes | Fault tree diagram showing event relationships |

| Use Cases | Design validation, risk management, process improvement | System safety analysis, root cause identification, reliability assessment |

| Complexity | Simple to moderate | Moderate to high |

| Data Requirements | Failure modes, effects, causes | System events, logic gates, failure probabilities |

| Strength | Early detection of failure modes, prioritizes corrective actions | Visualizes failure pathways, identifies minimal cut sets |

| Limitations | May miss complex interactions between failures | Requires detailed system knowledge, time-consuming |

Introduction to FMEA and Fault Tree Analysis

Failure Modes and Effects Analysis (FMEA) systematically identifies potential failure modes within a system and evaluates their impact on operations to prioritize risk mitigation efforts. Fault Tree Analysis (FTA) uses a top-down, deductive approach to map the logical relationships between failures leading to a specific undesired event through a graphical representation of fault trees. Both methodologies are critical in reliability engineering and risk management but differ in approach: FMEA emphasizes component-level failure identification and effects, whereas FTA focuses on system-level fault causality.

Defining FMEA: Purpose and Process

FMEA (Failure Modes and Effects Analysis) systematically identifies potential failure modes, their causes, and effects in a product or process to prioritize risks and implement corrective actions. It follows a structured step-by-step process including failure mode identification, effect analysis, severity rating, occurrence likelihood, detection controls, and Risk Priority Number (RPN) calculation. This proactive methodology helps organizations enhance reliability and safety by addressing failure causes before they occur, distinguishing it from Fault Tree Analysis, which focuses on deductive cause-effect fault logic.

Understanding Fault Tree Analysis: Structure and Application

Fault Tree Analysis (FTA) employs a top-down, deductive approach to identify the root causes of system failures by visually mapping events using logic gates like AND and OR. This structured method helps engineers systematically assess complex system reliability and safety by tracing faults from undesired outcomes back to basic events. FTA is widely applied in industries such as aerospace, nuclear, and automotive for risk assessment, design validation, and failure prevention.

Key Differences Between FMEA and Fault Tree Analysis

FMEA (Failure Modes and Effects Analysis) systematically examines potential failure modes within a system to identify their causes and effects, focusing on prevention at the component level. Fault Tree Analysis (FTA) uses a top-down approach to model the pathways leading to a specific system failure, emphasizing logical relationships and root cause identification through Boolean logic. The key difference lies in FMEA's bottom-up failure mode exploration versus FTA's top-down fault logic construction, making FMEA proactive and detailed in quantifying risk, while FTA provides a graphical overview of failure probabilities and dependencies.

Comparative Advantages in Industrial Engineering

FMEA offers a systematic approach to identify and prioritize potential failure modes based on severity, occurrence, and detectability, enhancing preventive maintenance in industrial engineering. Fault Tree Analysis excels in visualizing complex system failures through logic diagrams, facilitating root cause analysis and reliability improvement. Combining FMEA's detailed risk assessment with Fault Tree Analysis's top-down failure exploration enhances comprehensive failure prevention strategies in industrial settings.

Typical Use Cases for FMEA

FMEA (Failure Modes and Effects Analysis) is typically used in product design and manufacturing processes to identify and prioritize potential failure modes based on their severity, occurrence, and detectability. It is especially effective in early development stages for improving reliability and safety by addressing possible faults before they occur. Common applications include automotive systems, aerospace components, and medical device manufacturing where proactive risk mitigation is critical.

Typical Use Cases for Fault Tree Analysis

Fault Tree Analysis (FTA) is typically used for identifying the root causes of system-level failures in complex engineering systems, such as aerospace, nuclear power plants, and automotive safety systems. It excels in analyzing the probability and impact of specific failure events by visually mapping out logical relationships between faults. FTA is often employed during the design and safety assessment phases to support risk management and regulatory compliance in high-stakes industries.

Integration and Complementary Use of Both Methods

FMEA and Fault Tree Analysis (FTA) integrate effectively by combining FMEA's detailed failure mode identification with FTA's top-down causal analysis, enhancing overall risk management. Using FMEA to uncover potential failure modes supports constructing fault trees for systematic root cause investigation, improving design robustness. This complementary approach optimizes reliability engineering by leveraging FMEA's granular insights and FTA's structured visualization of failure pathways.

Selecting the Right Method for Industrial Applications

FMEA excels in identifying potential failure modes at the component or process level, making it ideal for preventive maintenance and design improvements in manufacturing. Fault Tree Analysis (FTA) provides a top-down approach to tracing system failures, beneficial for complex systems where understanding cause-and-effect relationships is critical. Selecting between FMEA and FTA depends on the industry's complexity, system hierarchy, and the need for either detailed failure mode identification or comprehensive fault causality mapping.

Future Trends in Risk Analysis Techniques

Future trends in risk analysis techniques emphasize integrating FMEA with advanced fault tree analysis through machine learning algorithms to enhance predictive accuracy and real-time data processing. The convergence of these methods facilitates dynamic risk modeling, enabling industries to identify complex failure modes and causal relationships more efficiently. Increasing adoption of AI-driven analytics and digital twins further revolutionizes fault detection and mitigation strategies, promoting proactive risk management across sectors.

Risk prioritization matrix

FMEA uses a Risk Priority Number (RPN) combining severity, occurrence, and detection ratings to prioritize risks, while Fault Tree Analysis identifies root causes through logical diagrams but lacks a standardized risk prioritization matrix.

Failure mode identification

FMEA systematically identifies potential failure modes by analyzing components and functions, while Fault Tree Analysis uses a top-down approach to trace the root causes of system failures.

Hazard analysis

FMEA systematically identifies potential failure modes and their impacts to prioritize hazard mitigation, while Fault Tree Analysis visually maps cause-effect relationships to diagnose root causes of hazards.

Root cause analysis

FMEA systematically identifies potential failure modes and their root causes by analyzing components individually, while Fault Tree Analysis uses a top-down approach to trace root causes of system failures through logical fault relationships.

Reliability block diagram

Reliability block diagrams visually represent system reliability by illustrating component interdependencies, while FMEA systematically identifies potential failure modes and fault tree analysis traces failure paths, making RBDs essential for quantifying system reliability outcomes derived from both FMEA and fault tree analysis data.

Event tree analysis

Event Tree Analysis (ETA) systematically evaluates potential outcomes following an initiating event by mapping sequential event paths, complementing FMEA's failure mode identification and Fault Tree Analysis's deductive cause exploration.

Severity ranking

FMEA assigns a Severity ranking to potential failure modes based on their impact on system performance, while Fault Tree Analysis emphasizes logical failure paths without explicitly ranking severity.

Criticality assessment

FMEA provides quantitative criticality assessment by combining failure occurrence, detection, and severity ratings, whereas Fault Tree Analysis evaluates criticality through probabilistic paths and logical relationships among system failures.

Preventive action planning

FMEA provides a detailed risk priority number to systematically identify and prioritize potential failure modes for preventive action planning, while Fault Tree Analysis visually maps the logical relationships between system failures to identify root causes and design effective preventive measures.

System redundancy evaluation

FMEA identifies potential failure modes and their impacts on system components, while Fault Tree Analysis visually maps system redundancies and failure combinations to evaluate overall system reliability.

FMEA vs fault tree analysis Infographic

njnir.com

njnir.com