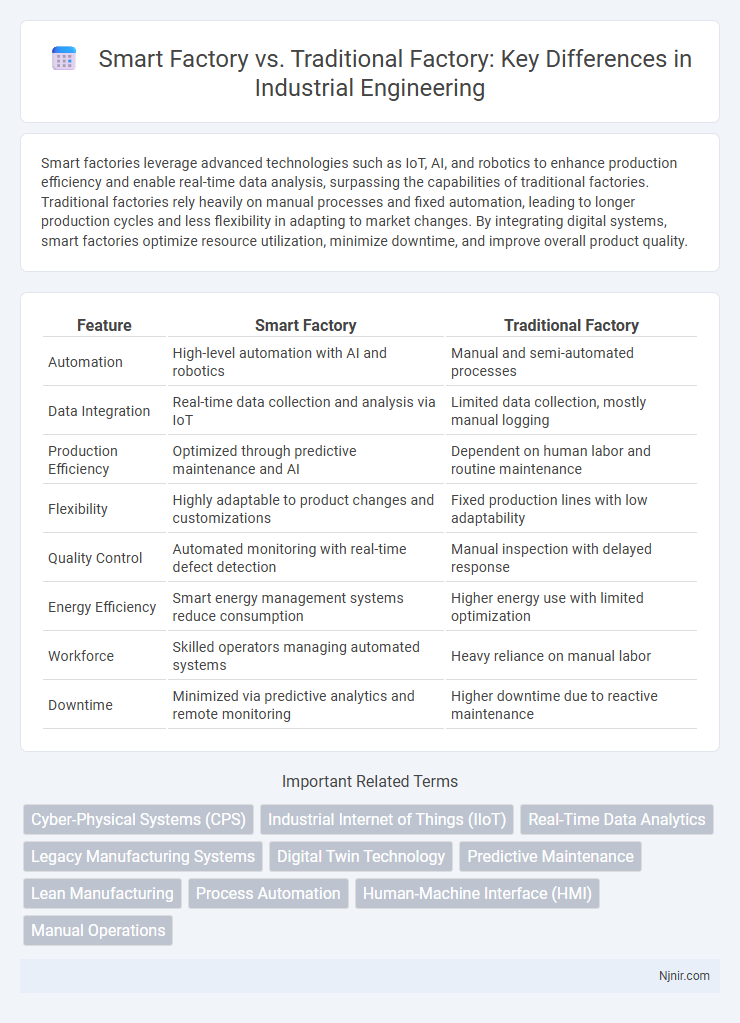

Smart factories leverage advanced technologies such as IoT, AI, and robotics to enhance production efficiency and enable real-time data analysis, surpassing the capabilities of traditional factories. Traditional factories rely heavily on manual processes and fixed automation, leading to longer production cycles and less flexibility in adapting to market changes. By integrating digital systems, smart factories optimize resource utilization, minimize downtime, and improve overall product quality.

Table of Comparison

| Feature | Smart Factory | Traditional Factory |

|---|---|---|

| Automation | High-level automation with AI and robotics | Manual and semi-automated processes |

| Data Integration | Real-time data collection and analysis via IoT | Limited data collection, mostly manual logging |

| Production Efficiency | Optimized through predictive maintenance and AI | Dependent on human labor and routine maintenance |

| Flexibility | Highly adaptable to product changes and customizations | Fixed production lines with low adaptability |

| Quality Control | Automated monitoring with real-time defect detection | Manual inspection with delayed response |

| Energy Efficiency | Smart energy management systems reduce consumption | Higher energy use with limited optimization |

| Workforce | Skilled operators managing automated systems | Heavy reliance on manual labor |

| Downtime | Minimized via predictive analytics and remote monitoring | Higher downtime due to reactive maintenance |

Introduction to Smart Factories and Traditional Factories

Smart factories integrate advanced technologies such as IoT, AI, and robotics to enhance automation, data exchange, and real-time decision-making in manufacturing processes. Traditional factories rely heavily on manual labor, mechanical equipment, and linear workflows, resulting in slower production cycles and limited adaptability. The transition to smart factories enables increased efficiency, predictive maintenance, and higher product quality compared to conventional manufacturing environments.

Key Technologies Enabling Smart Factories

Smart factories leverage cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics to optimize production processes and enhance real-time decision-making. Advanced robotics and automation systems enable higher precision and flexibility compared to traditional factories that rely heavily on manual labor and fixed machinery. Cloud computing and digital twin technology provide smart factories with scalable, interconnected platforms for continuous monitoring and predictive maintenance, driving efficiency and reducing downtime.

Production Efficiency: Smart vs Traditional Approaches

Smart factories leverage advanced automation, IoT sensors, and real-time data analytics to optimize production efficiency, significantly reducing downtime and waste compared to traditional factories. Traditional factories rely heavily on manual processes and fixed schedules, often resulting in slower response times to production issues and higher operational costs. The integration of AI and machine learning in smart factories enables predictive maintenance and dynamic resource allocation, driving superior throughput and cost savings over conventional manufacturing methods.

Automation Levels and Human Involvement

Smart factories utilize advanced automation technologies such as IoT, AI, and robotics to achieve higher levels of automation with minimal human intervention, enhancing efficiency and precision in production processes. Traditional factories rely heavily on manual labor and human supervision, resulting in lower automation levels and increased potential for human error. The integration of real-time data analytics in smart factories reduces the need for human decision-making, whereas traditional factories depend on human expertise for operational adjustments.

Data Utilization and Real-Time Monitoring

Smart factories leverage advanced data utilization techniques and real-time monitoring systems to optimize production efficiency, reduce downtime, and enhance quality control, utilizing IoT sensors, AI analytics, and cloud computing for instantaneous decision-making. In contrast, traditional factories rely heavily on manual data collection and periodic inspections, leading to delayed responses to operational issues and less precise process management. The integration of automated data streams and continuous monitoring in smart factories allows for predictive maintenance and dynamic resource allocation, significantly outperforming traditional manufacturing environments in responsiveness and productivity.

Flexibility and Customization Capabilities

Smart factories offer superior flexibility and customization capabilities by integrating advanced automation, IoT sensors, and real-time data analytics, allowing rapid adjustments in production lines to meet diverse customer demands. Traditional factories rely on fixed machinery and manual processes, limiting their ability to quickly adapt to custom orders or variable production volumes. The enhanced adaptability of smart factories enables mass customization and shorter lead times, driving increased competitiveness in dynamic markets.

Quality Control and Defect Reduction

Smart factories leverage real-time data analytics and automated inspection systems to enhance quality control, significantly reducing defect rates compared to traditional factories that rely on manual inspections and periodic sampling. Advanced sensors, machine learning algorithms, and predictive maintenance in smart factories detect anomalies early, minimizing production errors and ensuring consistent product quality. This shift leads to higher efficiency, lower waste, and improved customer satisfaction by addressing defects proactively rather than reactively.

Energy Consumption and Sustainability

Smart factories leverage advanced IoT sensors and AI-driven automation to optimize energy consumption, resulting in up to 30% reduction in electricity usage compared to traditional factories. These facilities implement real-time energy monitoring and predictive maintenance, minimizing waste and enhancing sustainability by lowering carbon emissions. Traditional factories typically rely on fixed schedules and manual oversight, leading to higher energy inefficiencies and a larger environmental footprint.

Cost Implications and Return on Investment

Smart factories leverage automation, IoT, and data analytics to significantly reduce operational costs by minimizing downtime and optimizing resource use, unlike traditional factories reliant on manual processes and fixed schedules. Initial capital expenditure for smart factories is higher due to investment in advanced machinery and software, but the enhanced efficiency accelerates return on investment (ROI), often within a few years. Long-term savings from predictive maintenance, energy efficiency, and reduced labor costs contribute to a higher ROI compared to traditional manufacturing setups.

Future Trends in Industrial Engineering

Smart factories leverage IoT, AI, and automation to enhance efficiency, flexibility, and real-time decision-making compared to traditional factories reliant on manual processes and static production lines. Future trends in industrial engineering emphasize digital twins, predictive maintenance, and cyber-physical systems to optimize operations and reduce downtime. The integration of big data analytics and machine learning in smart factories drives continuous improvement and sustainable manufacturing practices.

Cyber-Physical Systems (CPS)

Smart factories utilize advanced Cyber-Physical Systems (CPS) integrating real-time data analytics and automated control, significantly enhancing efficiency and adaptability compared to traditional factories reliant on manual processes and isolated machinery.

Industrial Internet of Things (IIoT)

Smart factories leverage the Industrial Internet of Things (IIoT) to enable real-time data analytics, predictive maintenance, and automated processes, significantly enhancing efficiency and reducing downtime compared to traditional factories.

Real-Time Data Analytics

Smart factories leverage real-time data analytics to optimize production efficiency, reduce downtime, and enable predictive maintenance, unlike traditional factories which rely on manual data collection and delayed analysis.

Legacy Manufacturing Systems

Legacy manufacturing systems in traditional factories limit efficiency and adaptability, whereas smart factories leverage advanced automation and real-time data analytics for optimized production and reduced downtime.

Digital Twin Technology

Digital Twin Technology in smart factories enables real-time simulation and optimization of production processes, significantly improving efficiency and reducing downtime compared to traditional factories.

Predictive Maintenance

Smart factories enhance predictive maintenance by using IoT sensors and AI analytics to forecast equipment failures, reducing downtime compared to traditional factories that rely on scheduled or reactive maintenance.

Lean Manufacturing

Smart factories enhance Lean Manufacturing by integrating real-time data analytics, automation, and IoT connectivity to minimize waste and optimize production efficiency compared to traditional factories.

Process Automation

Smart factories leverage advanced process automation technologies such as IoT sensors, AI-driven robotics, and real-time data analytics to optimize efficiency and reduce errors, whereas traditional factories rely heavily on manual operations and limited automation.

Human-Machine Interface (HMI)

Smart factories utilize advanced Human-Machine Interface (HMI) technologies like touchscreens and augmented reality to enhance operator interaction and efficiency, while traditional factories rely on basic controls and manual monitoring with limited real-time data integration.

Manual Operations

Smart factories minimize manual operations through automation and real-time data integration, enhancing efficiency compared to traditional factories reliant on extensive manual labor.

smart factory vs traditional factory Infographic

njnir.com

njnir.com