Green manufacturing emphasizes reducing environmental impact through energy-efficient processes and minimizing waste, aiming for eco-friendly production. Sustainable manufacturing expands this focus by integrating social responsibility and economic viability, ensuring long-term benefits for communities and businesses. Both approaches prioritize resource conservation but differ in scope, with sustainable manufacturing adopting a holistic view of environmental, social, and economic factors.

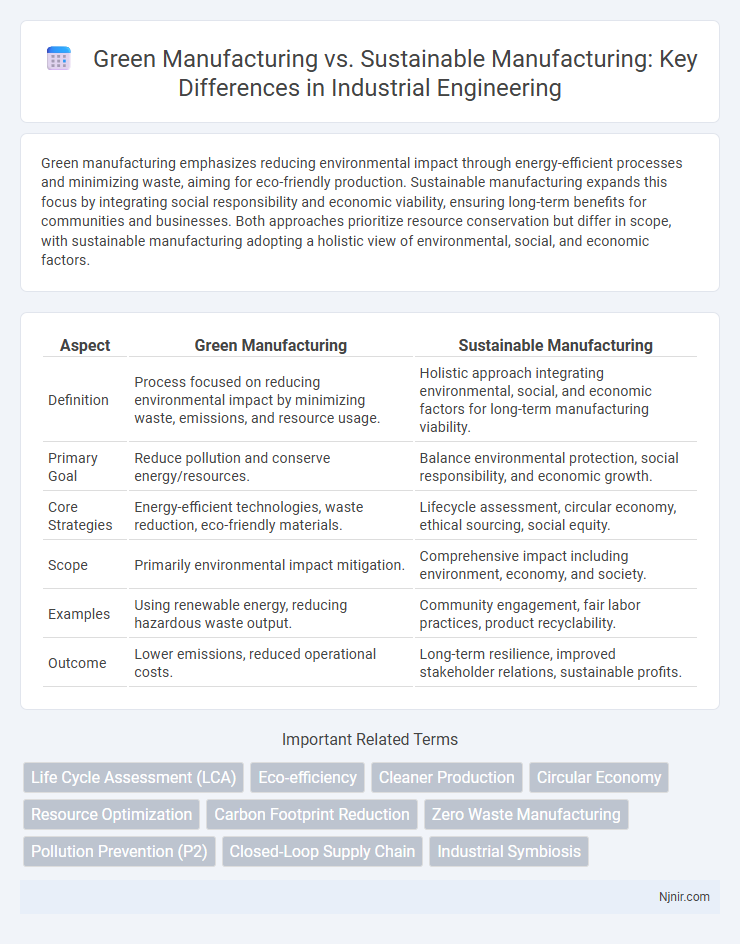

Table of Comparison

| Aspect | Green Manufacturing | Sustainable Manufacturing |

|---|---|---|

| Definition | Process focused on reducing environmental impact by minimizing waste, emissions, and resource usage. | Holistic approach integrating environmental, social, and economic factors for long-term manufacturing viability. |

| Primary Goal | Reduce pollution and conserve energy/resources. | Balance environmental protection, social responsibility, and economic growth. |

| Core Strategies | Energy-efficient technologies, waste reduction, eco-friendly materials. | Lifecycle assessment, circular economy, ethical sourcing, social equity. |

| Scope | Primarily environmental impact mitigation. | Comprehensive impact including environment, economy, and society. |

| Examples | Using renewable energy, reducing hazardous waste output. | Community engagement, fair labor practices, product recyclability. |

| Outcome | Lower emissions, reduced operational costs. | Long-term resilience, improved stakeholder relations, sustainable profits. |

Understanding Green Manufacturing: Key Concepts

Green manufacturing emphasizes reducing environmental impact through energy-efficient processes, waste minimization, and the use of non-toxic materials. It integrates renewable energy sources and pollution control technologies to lower carbon footprints and resource consumption. Key concepts include lifecycle analysis, eco-friendly product design, and compliance with environmental regulations to promote sustainable industrial practices.

Defining Sustainable Manufacturing: Scope and Goals

Sustainable manufacturing encompasses a holistic approach that integrates environmental stewardship, economic viability, and social responsibility throughout the entire production lifecycle. Its scope extends beyond minimizing waste and energy consumption to include the use of renewable resources, reduction of greenhouse gas emissions, and enhancement of worker health and community well-being. The primary goals focus on creating products that meet present needs without compromising the ability of future generations to satisfy their own, emphasizing long-term systemic impacts rather than isolated environmental improvements.

Core Principles: Green vs Sustainable Manufacturing

Green manufacturing focuses on minimizing environmental impact through energy efficiency, waste reduction, and pollution prevention during production processes. Sustainable manufacturing encompasses broader principles, integrating economic viability, social responsibility, and long-term resource stewardship alongside environmental protection. Core differences highlight green manufacturing's emphasis on ecological improvements, while sustainable manufacturing prioritizes a balance among environmental, economic, and social dimensions.

Environmental Impact: Comparing Green and Sustainable Approaches

Green manufacturing reduces environmental impact by minimizing waste, using renewable energy, and implementing eco-friendly materials to lower carbon emissions. Sustainable manufacturing goes further by integrating long-term resource management, social responsibility, and economic viability to ensure practices do not deplete natural resources over time. Both approaches prioritize reducing pollution, but sustainable manufacturing emphasizes a holistic balance between environmental preservation, economic growth, and social equity.

Resource Efficiency and Waste Management

Green manufacturing emphasizes reducing environmental impact by minimizing waste and optimizing energy use through eco-friendly processes, prioritizing resource efficiency to lower raw material consumption. Sustainable manufacturing extends these principles by integrating economic and social factors, promoting circular economy practices that improve waste management through recycling, reuse, and reducing emissions across the entire product lifecycle. Both approaches aim to enhance resource efficiency, but sustainable manufacturing offers a broader framework that includes long-term environmental stewardship and responsible waste management strategies.

Social Responsibility in Manufacturing Practices

Green manufacturing emphasizes reducing environmental impact through energy-efficient processes and waste minimization, directly benefiting community health and safety. Sustainable manufacturing expands this by integrating social responsibility, promoting fair labor practices, worker well-being, and community engagement alongside environmental goals. Companies adopting sustainable manufacturing demonstrate commitment to ethical sourcing, employee rights, and long-term societal welfare, creating a positive social footprint beyond green initiatives.

Economic Implications of Green and Sustainable Manufacturing

Green manufacturing emphasizes reducing environmental impact through energy-efficient processes and waste minimization, leading to lower operational costs and potential tax incentives. Sustainable manufacturing expands this approach by integrating long-term resource management and social responsibility, which can enhance brand value and improve market competitiveness. Both strategies contribute to economic resilience by optimizing supply chains and reducing regulatory risks, but sustainable manufacturing often requires higher initial investments with greater long-term financial benefits.

Technological Innovations Driving Change

Technological innovations such as AI-driven analytics and IoT-enabled machinery are revolutionizing green manufacturing by minimizing waste and optimizing resource efficiency. Sustainable manufacturing leverages advancements in renewable energy integration and biodegradable materials to reduce environmental impact across entire supply chains. These technologies collectively propel the transition from traditional practices to eco-conscious production systems with measurable ecological and economic benefits.

Regulatory Frameworks and Compliance

Green manufacturing emphasizes reducing environmental impact through energy-efficient processes and pollution control, often driven by specific regulations like the Clean Air Act and water discharge permits. Sustainable manufacturing extends beyond environmental factors to include social and economic dimensions, complying with broader frameworks such as ISO 14001 and the United Nations Sustainable Development Goals (SDGs). Both approaches require adherence to local, national, and international standards, but sustainable manufacturing demands integrated compliance strategies addressing environmental, social, and corporate governance (ESG) criteria.

Future Trends: Integrating Green and Sustainable Strategies

Future trends in manufacturing emphasize the integration of green manufacturing techniques, such as waste minimization and energy-efficient processes, with comprehensive sustainable manufacturing strategies that prioritize lifecycle impacts and social responsibility. Advanced technologies like AI-driven process optimization and circular economy models enhance resource efficiency and reduce environmental footprints simultaneously. Increasing regulatory pressure and consumer demand drive the adoption of these hybrid approaches, positioning companies for long-term resilience and competitive advantage.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) distinguishes green manufacturing by minimizing environmental impact during production, while sustainable manufacturing integrates LCA to optimize resource efficiency and social responsibility throughout the entire product lifecycle.

Eco-efficiency

Green manufacturing emphasizes reducing environmental impact through eco-efficient processes that minimize waste and energy use, while sustainable manufacturing integrates eco-efficiency with social responsibility and long-term resource management to achieve holistic environmental and economic benefits.

Cleaner Production

Green manufacturing emphasizes reducing environmental impact through cleaner production techniques, while sustainable manufacturing integrates economic and social factors alongside cleaner production for long-term resource efficiency.

Circular Economy

Green manufacturing minimizes environmental impact through resource efficiency, while sustainable manufacturing advances circular economy principles by integrating waste reduction, product lifecycle extension, and renewable resource usage.

Resource Optimization

Green manufacturing emphasizes reducing environmental impact through resource optimization techniques such as energy-efficient processes and waste minimization, while sustainable manufacturing integrates resource optimization with long-term economic viability and social responsibility to achieve holistic environmental stewardship.

Carbon Footprint Reduction

Green manufacturing emphasizes minimizing carbon footprint through energy-efficient processes, while sustainable manufacturing integrates carbon reduction with resource conservation and social responsibility for holistic environmental impact.

Zero Waste Manufacturing

Zero Waste Manufacturing emphasizes eliminating waste entirely through circular processes, making it a critical component of both green manufacturing and sustainable manufacturing strategies aimed at minimizing environmental impact.

Pollution Prevention (P2)

Green manufacturing emphasizes minimizing environmental impact through energy efficiency and waste reduction, while sustainable manufacturing integrates Pollution Prevention (P2) by systematically designing processes to eliminate waste and reduce emissions throughout the entire product lifecycle.

Closed-Loop Supply Chain

Closed-Loop Supply Chain in sustainable manufacturing integrates recyclable materials and product lifecycle management more comprehensively than traditional green manufacturing, enhancing resource efficiency and waste reduction.

Industrial Symbiosis

Industrial symbiosis enhances sustainable manufacturing by promoting resource sharing and waste minimization beyond the green manufacturing focus on environmental efficiency.

Green manufacturing vs Sustainable manufacturing Infographic

njnir.com

njnir.com