Discrete manufacturing produces distinct, countable products such as automobiles or electronics, relying heavily on assembly lines and component parts. Process manufacturing involves continuous or batch production of goods like chemicals, food, or beverages, emphasizing formulas and recipes rather than individual units. Understanding these differences is crucial for optimizing production planning, inventory management, and supply chain strategies in industrial engineering.

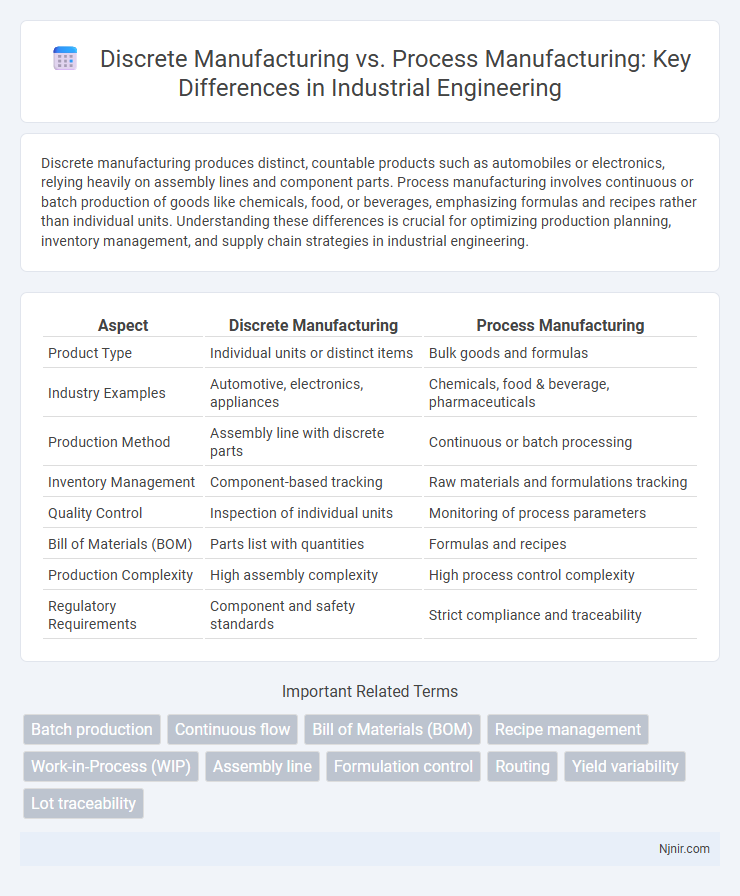

Table of Comparison

| Aspect | Discrete Manufacturing | Process Manufacturing |

|---|---|---|

| Product Type | Individual units or distinct items | Bulk goods and formulas |

| Industry Examples | Automotive, electronics, appliances | Chemicals, food & beverage, pharmaceuticals |

| Production Method | Assembly line with discrete parts | Continuous or batch processing |

| Inventory Management | Component-based tracking | Raw materials and formulations tracking |

| Quality Control | Inspection of individual units | Monitoring of process parameters |

| Bill of Materials (BOM) | Parts list with quantities | Formulas and recipes |

| Production Complexity | High assembly complexity | High process control complexity |

| Regulatory Requirements | Component and safety standards | Strict compliance and traceability |

Introduction to Discrete and Process Manufacturing

Discrete manufacturing involves the production of distinct, countable items such as automobiles, electronics, and furniture, emphasizing assembly and customization. Process manufacturing focuses on the production of goods from formulas or recipes, like chemicals, pharmaceuticals, and food products, where the output is typically measured in bulk or volume. Understanding the differences in workflows, inventory management, and quality control between these two manufacturing types is crucial for optimizing operational efficiency.

Defining Discrete Manufacturing

Discrete manufacturing involves the production of distinct items such as automobiles, electronics, and furniture, where individual units can be counted and identified. This method relies on assembly lines and specific parts or components that are combined in a series of steps to create the final product. The emphasis on inventory management, bill of materials, and traceability distinguishes discrete manufacturing from continuous or batch processes found in process manufacturing.

Defining Process Manufacturing

Process manufacturing involves producing goods by combining raw materials through formulas or recipes, resulting in products that are typically bulk, homogeneous, and difficult to disassemble, such as chemicals, pharmaceuticals, and food. Unlike discrete manufacturing, which produces distinct items like cars or electronics, process manufacturing relies heavily on continuous production processes and precise adherence to batch specifications. Key characteristics include traceability, quality control, and regulatory compliance to ensure consistent output in industries such as chemicals, petrochemicals, and consumer packaged goods.

Key Differences Between Discrete and Process Manufacturing

Discrete manufacturing produces distinct, countable products like cars, electronics, or furniture using assembly lines, focusing on parts and components with traceability. Process manufacturing involves formulas and recipes to produce bulk goods such as chemicals, food, or pharmaceuticals, emphasizing continuous production and exact ingredient measurements. Key differences include the nature of output, production methods, inventory tracking, and quality control processes unique to each manufacturing type.

Industry Applications for Discrete Manufacturing

Discrete manufacturing is prevalent in industries such as automotive, aerospace, electronics, and machinery where products are assembled from distinct components. This sector relies heavily on precise inventory management, assembly line optimization, and quality control to produce finished goods like vehicles, consumer electronics, and industrial equipment. Advanced technologies such as CAD/CAM and robotics enhance production efficiency and customization capabilities in discrete manufacturing environments.

Industry Applications for Process Manufacturing

Process manufacturing is widely applied in industries such as chemical, pharmaceutical, food and beverage, and petrochemical sectors where raw materials undergo continuous or batch chemical transformations. This approach is optimal for producing goods like paints, medications, and packaged foods that require precise formulation and consistency. These industries benefit from process manufacturing's emphasis on quality control, regulatory compliance, and scalability in production.

Production Processes: Batch vs. Continuous Flow

Discrete manufacturing involves the production of distinct items like automobiles or electronics using batch production processes, where products are created in specific quantities and stages. Process manufacturing produces goods such as chemicals or beverages through continuous flow processes, maintaining an ongoing, unbroken operation that enhances efficiency and consistency. Batch production allows for flexibility and customization, while continuous flow emphasizes large-scale, uniform output.

Quality Control in Discrete vs. Process Manufacturing

Quality control in discrete manufacturing emphasizes inspection and testing of individual units to ensure product conformity, leveraging traceability and defect detection at the component level. In process manufacturing, quality control focuses on monitoring continuous processes, controlling batch consistency, and maintaining parameters such as temperature, pressure, and chemical composition to prevent deviations and ensure product uniformity. Advanced quality control systems in process manufacturing use real-time data analytics and automation to detect variations early, minimizing waste and ensuring compliance with industry standards.

Technology and Automation in Both Manufacturing Types

Discrete manufacturing utilizes advanced robotics and CNC machines to produce individual units with high precision, leveraging automation software for inventory management and quality control. Process manufacturing employs distributed control systems (DCS) and programmable logic controllers (PLC) to maintain continuous production flows, with automation optimizing batch consistency and reducing waste. Both manufacturing types integrate Industrial Internet of Things (IIoT) technologies and data analytics to enhance operational efficiency and predictive maintenance.

Choosing the Right Manufacturing Approach for Your Business

Discrete manufacturing involves producing distinct items such as cars, electronics, or furniture with assembly and component tracking, while process manufacturing focuses on formulas or recipes for products like food, chemicals, and pharmaceuticals where blending and batch control are critical. Choosing the right manufacturing approach depends on factors like product type, production volume, customization level, and supply chain complexity to optimize efficiency and reduce costs. Integrating ERP software tailored for either discrete or process manufacturing enhances operational visibility, quality control, and compliance adherence.

Batch production

Batch production in discrete manufacturing involves assembling distinct units or parts in set quantities, while process manufacturing focuses on producing goods by mixing or chemical processes in continuous or semi-continuous batch runs.

Continuous flow

Continuous flow in process manufacturing ensures uninterrupted production through liquids, gases, or powders, contrasting with discrete manufacturing's assembly of distinct, countable units.

Bill of Materials (BOM)

Discrete manufacturing uses a hierarchical, variant-driven Bill of Materials (BOM) to detail individual components and assemblies, while process manufacturing relies on a formulation-based BOM emphasizing ingredient quantities and batch recipes.

Recipe management

Recipe management in discrete manufacturing involves precise bill of materials and routing control, whereas process manufacturing emphasizes formula-based batch consistency and ingredient traceability for product quality.

Work-in-Process (WIP)

Work-in-Process (WIP) in discrete manufacturing involves tracking individual units or components through assembly stages, while process manufacturing manages WIP as bulk materials flowing continuously through chemical or physical processes.

Assembly line

Discrete manufacturing involves assembly lines producing distinct, countable products like cars or electronics, while process manufacturing uses continuous flow production for goods like chemicals or food, emphasizing batch processing over assembly.

Formulation control

Formulation control in process manufacturing precisely manages ingredient proportions and chemical reactions for consistent product quality, unlike discrete manufacturing which emphasizes part assembly and configuration control.

Routing

Discrete manufacturing routing involves distinct, sequential steps for assembling individual units, while process manufacturing routing emphasizes continuous, formula-based operations optimized for batch production.

Yield variability

Yield variability in discrete manufacturing is typically lower due to consistent production of individual units, whereas process manufacturing experiences higher yield variability because of continuous chemical or physical transformations affecting batch consistency.

Lot traceability

Discrete manufacturing requires precise lot traceability to track individual units through production, while process manufacturing emphasizes batch-level lot traceability to monitor continuous or bulk production flows.

Discrete manufacturing vs Process manufacturing Infographic

njnir.com

njnir.com