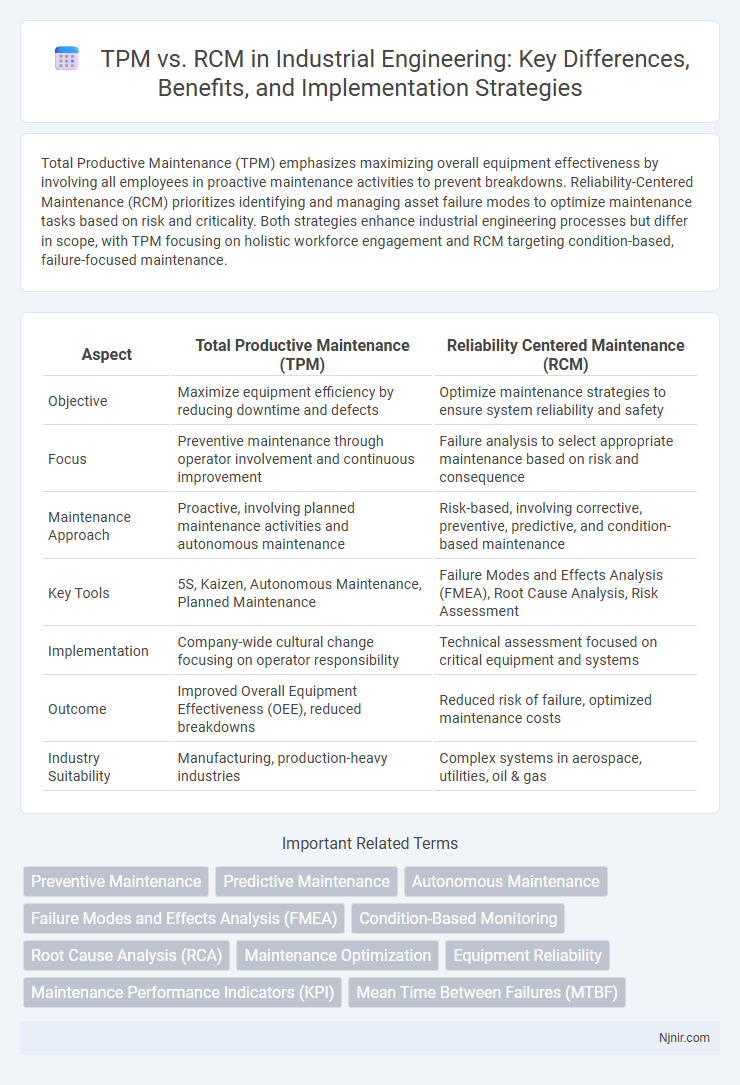

Total Productive Maintenance (TPM) emphasizes maximizing overall equipment effectiveness by involving all employees in proactive maintenance activities to prevent breakdowns. Reliability-Centered Maintenance (RCM) prioritizes identifying and managing asset failure modes to optimize maintenance tasks based on risk and criticality. Both strategies enhance industrial engineering processes but differ in scope, with TPM focusing on holistic workforce engagement and RCM targeting condition-based, failure-focused maintenance.

Table of Comparison

| Aspect | Total Productive Maintenance (TPM) | Reliability Centered Maintenance (RCM) |

|---|---|---|

| Objective | Maximize equipment efficiency by reducing downtime and defects | Optimize maintenance strategies to ensure system reliability and safety |

| Focus | Preventive maintenance through operator involvement and continuous improvement | Failure analysis to select appropriate maintenance based on risk and consequence |

| Maintenance Approach | Proactive, involving planned maintenance activities and autonomous maintenance | Risk-based, involving corrective, preventive, predictive, and condition-based maintenance |

| Key Tools | 5S, Kaizen, Autonomous Maintenance, Planned Maintenance | Failure Modes and Effects Analysis (FMEA), Root Cause Analysis, Risk Assessment |

| Implementation | Company-wide cultural change focusing on operator responsibility | Technical assessment focused on critical equipment and systems |

| Outcome | Improved Overall Equipment Effectiveness (OEE), reduced breakdowns | Reduced risk of failure, optimized maintenance costs |

| Industry Suitability | Manufacturing, production-heavy industries | Complex systems in aerospace, utilities, oil & gas |

Introduction to TPM and RCM in Industrial Engineering

Total Productive Maintenance (TPM) is a proactive maintenance strategy in industrial engineering aimed at maximizing equipment effectiveness through operator involvement and continuous improvement. Reliability-Centered Maintenance (RCM) focuses on identifying critical assets and applying tailored maintenance tasks to ensure system reliability and safety. Both methodologies optimize maintenance workflows but differ in scope, with TPM emphasizing overall equipment efficiency and RCM targeting risk-based reliability.

Core Principles of Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance to maximize equipment effectiveness and eliminate breakdowns. Core principles include autonomous maintenance by operators, planned maintenance schedules, focused improvement teams, and comprehensive training to enhance equipment reliability and workforce skills. TPM aims to create a culture of continuous improvement by integrating maintenance into daily operations, fostering collaboration, and promoting equipment ownership.

Core Principles of Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) centers on identifying critical assets and failure modes to prioritize maintenance tasks that ensure system reliability and safety. The core principles emphasize understanding the function and potential failure of equipment, selecting appropriate maintenance strategies, and optimizing resources to prevent unexpected failures. Unlike Total Productive Maintenance (TPM), which focuses broadly on overall equipment effectiveness and operator involvement, RCM provides a systematic approach to maintenance planning based on risk assessment and reliability data.

Key Differences Between TPM and RCM

TPM (Total Productive Maintenance) emphasizes proactive and preventive maintenance through employee involvement to maximize equipment effectiveness, while RCM (Reliability-Centered Maintenance) prioritizes identifying the most critical assets and applying maintenance strategies based on reliability and failure modes analysis. TPM seeks to eliminate all equipment downtime by fostering autonomous maintenance and continuous improvement, whereas RCM focuses on optimizing maintenance tactics to balance cost, safety, and operational risk. Key differences include TPM's organization-wide engagement for daily equipment care versus RCM's analytical framework targeting specific failure consequences for strategic maintenance decisions.

Objectives and Outcomes: TPM vs RCM

Total Productive Maintenance (TPM) aims to maximize equipment effectiveness by involving all employees in proactive and preventive maintenance, reducing downtime and improving productivity. Reliability-Centered Maintenance (RCM) focuses on identifying critical assets and optimizing maintenance strategies based on risk and reliability analysis to ensure asset functionality and safety. TPM outcomes enhance operational efficiency and employee engagement, while RCM delivers targeted reliability improvements and cost-effective maintenance prioritization.

Implementation Process for TPM

The implementation process for Total Productive Maintenance (TPM) involves establishing cross-functional teams to empower operators in preventive maintenance tasks, enhancing equipment reliability and minimizing downtime. Key steps include initial equipment evaluation, focused training for all employees, and setting measurable targets to track improvements in overall equipment effectiveness (OEE). TPM emphasizes continuous improvement through regular autonomous maintenance activities, fostering a culture of proactive problem-solving and sustained production efficiency.

Implementation Process for RCM

The implementation process for Reliability-Centered Maintenance (RCM) involves identifying critical assets and analyzing their functions and potential failure modes through Failure Modes and Effects Analysis (FMEA). This approach prioritizes maintenance tasks based on risk assessment to enhance system reliability and safety. Data-driven decision making and cross-functional team collaboration are essential for tailoring maintenance strategies that align with operational goals.

Suitability of TPM and RCM for Different Industries

Total Productive Maintenance (TPM) is highly suitable for manufacturing industries that emphasize continuous production and equipment efficiency, such as automotive and electronics, where minimizing downtime is critical. Reliability-Centered Maintenance (RCM) fits best in industries like aviation, oil and gas, and power generation, where safety, risk management, and complex system reliability are paramount. TPM targets proactive operator-driven maintenance to boost overall productivity, while RCM uses a structured approach to prioritize maintenance based on failure consequences, aligning with industry-specific safety and operational priorities.

Challenges and Best Practices in Applying TPM and RCM

Challenges in applying TPM and RCM include aligning maintenance strategies with asset criticality and managing organizational resistance to change. Best practices involve integrating data-driven decision-making for precise failure analysis in RCM and fostering cross-functional collaboration to enhance employee engagement in TPM. Leveraging advanced analytics and continuous training ensures optimized maintenance schedules and maximized equipment reliability.

Case Studies: TPM vs RCM Performance in Industry

Case studies reveal that Total Productive Maintenance (TPM) enhances overall equipment effectiveness by reducing downtime and fostering operator involvement, particularly in manufacturing environments. Reliability-Centered Maintenance (RCM) excels in industries with complex systems, such as aerospace and power generation, by prioritizing maintenance tasks based on failure modes and risk assessment. Comparative analyses show TPM drives continuous improvement through proactive maintenance culture, while RCM optimizes maintenance resources by targeting critical asset functions to maximize reliability and safety.

Preventive Maintenance

Preventive Maintenance in TPM emphasizes routine equipment care to reduce breakdowns, while RCM prioritizes failure mode analysis to optimize maintenance tasks based on criticality and risk.

Predictive Maintenance

Predictive Maintenance in TPM uses real-time data and advanced analytics to anticipate equipment failures, while RCM prioritizes asset reliability through failure mode analysis and maintenance strategy optimization.

Autonomous Maintenance

Autonomous Maintenance in TPM empowers operators to perform routine equipment upkeep, reducing downtime and enhancing reliability compared to the predictive focus of RCM.

Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) is integral to Reliability-Centered Maintenance (RCM) for systematically identifying and prioritizing potential failure impacts, whereas Total Productive Maintenance (TPM) emphasizes operator-driven prevention and overall equipment effectiveness without formal FMEA processes.

Condition-Based Monitoring

Condition-Based Monitoring in TPM emphasizes routine equipment checks, while RCM prioritizes predictive maintenance by analyzing real-time data to optimize asset reliability.

Root Cause Analysis (RCA)

Root Cause Analysis (RCA) in TPM focuses on continuous employee-driven problem solving to prevent equipment failures, while in RCM it emphasizes systematic failure mode identification and prioritization to optimize maintenance strategies.

Maintenance Optimization

Total Productive Maintenance (TPM) enhances equipment reliability through operator involvement and preventive care, while Reliability-Centered Maintenance (RCM) focuses on optimizing maintenance tasks based on failure modes and risk assessment to maximize asset availability.

Equipment Reliability

Total Productive Maintenance (TPM) enhances equipment reliability by involving operators in proactive maintenance, while Reliability-Centered Maintenance (RCM) improves reliability through systematic analysis of failure modes and tailored maintenance strategies.

Maintenance Performance Indicators (KPI)

TPM focuses on Overall Equipment Effectiveness (OEE) and Autonomous Maintenance rates as key KPIs, while RCM emphasizes Failure Mode Frequency and Maintenance Cost per Failure to optimize maintenance performance.

Mean Time Between Failures (MTBF)

Total Productive Maintenance (TPM) emphasizes enhancing overall equipment effectiveness, while Reliability-Centered Maintenance (RCM) focuses on optimizing Mean Time Between Failures (MTBF) by prioritizing maintenance tasks based on failure impact and probability.

TPM vs RCM Infographic

njnir.com

njnir.com