Condition monitoring involves real-time tracking of equipment performance to detect faults and prevent unexpected breakdowns, relying on sensors and data acquisition systems. Predictive analytics uses historical and real-time data combined with machine learning algorithms to forecast equipment failures and optimize maintenance schedules. Integrating predictive analytics with condition monitoring enhances decision-making by identifying patterns and trends that enable proactive maintenance interventions.

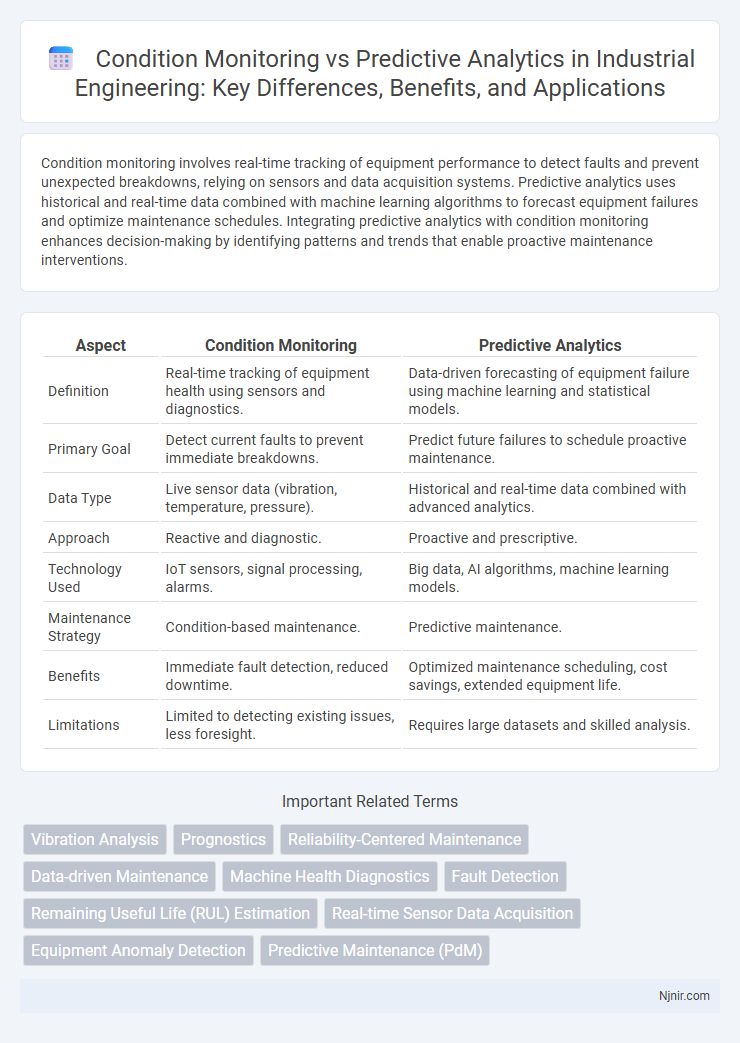

Table of Comparison

| Aspect | Condition Monitoring | Predictive Analytics |

|---|---|---|

| Definition | Real-time tracking of equipment health using sensors and diagnostics. | Data-driven forecasting of equipment failure using machine learning and statistical models. |

| Primary Goal | Detect current faults to prevent immediate breakdowns. | Predict future failures to schedule proactive maintenance. |

| Data Type | Live sensor data (vibration, temperature, pressure). | Historical and real-time data combined with advanced analytics. |

| Approach | Reactive and diagnostic. | Proactive and prescriptive. |

| Technology Used | IoT sensors, signal processing, alarms. | Big data, AI algorithms, machine learning models. |

| Maintenance Strategy | Condition-based maintenance. | Predictive maintenance. |

| Benefits | Immediate fault detection, reduced downtime. | Optimized maintenance scheduling, cost savings, extended equipment life. |

| Limitations | Limited to detecting existing issues, less foresight. | Requires large datasets and skilled analysis. |

Defining Condition Monitoring in Industrial Engineering

Condition monitoring in industrial engineering involves the continuous or periodic measurement of equipment parameters such as vibration, temperature, and pressure to detect signs of wear, faults, or degradation. This real-time assessment enables early identification of potential issues, minimizing unplanned downtime and optimizing maintenance schedules. Predictive analytics builds on this data by using advanced algorithms and machine learning to forecast equipment failures and recommend proactive interventions.

Understanding Predictive Analytics for Industrial Systems

Predictive analytics for industrial systems employs advanced algorithms and real-time data to forecast equipment failures and optimize maintenance schedules. Unlike condition monitoring, which detects current asset health through sensors and performance metrics, predictive analytics analyzes historical data patterns and machine learning models to anticipate future issues. Implementing predictive analytics enhances operational efficiency by enabling proactive decision-making and reducing unplanned downtime in industrial environments.

Key Differences Between Condition Monitoring and Predictive Analytics

Condition monitoring involves real-time tracking of equipment performance through sensors to detect anomalies, while predictive analytics uses historical and real-time data combined with machine learning algorithms to forecast future failures. Condition monitoring primarily focuses on current asset health status, whereas predictive analytics provides insights into potential future issues to enable proactive maintenance. The key difference lies in condition monitoring's emphasis on immediate detection versus predictive analytics' emphasis on anticipatory maintenance strategy.

Data Collection Techniques for Condition Monitoring

Condition monitoring relies on data collection techniques such as vibration analysis, thermography, ultrasonic testing, and oil analysis to continuously track the health of equipment. Sensors capture real-time operational data, providing early warning signs of wear, misalignment, or impending failure. These methods enable proactive maintenance by identifying anomalies before they lead to costly breakdowns.

Machine Learning in Predictive Analytics

Condition monitoring involves real-time data collection from machinery to detect anomalies and assess equipment health, while predictive analytics leverages machine learning algorithms to analyze historical and real-time data for forecasting potential failures before they occur. Machine learning models in predictive analytics identify complex patterns and trends within sensor data, enabling proactive maintenance decisions that reduce downtime and extend asset life. This advanced approach surpasses traditional condition monitoring by providing actionable insights through continuous learning and adaptation to evolving operational conditions.

Benefits of Condition Monitoring in Manufacturing

Condition monitoring in manufacturing enhances equipment reliability by continuously tracking machinery parameters such as vibration, temperature, and pressure, enabling early detection of potential failures. This real-time data collection reduces unplanned downtime and maintenance costs while extending asset lifespan. Implementing condition monitoring supports optimized production schedules and improves overall operational efficiency.

Predictive Analytics for Asset Reliability

Predictive analytics leverages advanced machine learning algorithms and real-time sensor data to forecast asset failures before they occur, enhancing reliability and reducing unplanned downtime. Unlike traditional condition monitoring, which relies on detecting current anomalies, predictive analytics uses historical and operational data trends to anticipate issues, enabling proactive maintenance strategies. Key tools in predictive analytics include AI-driven models, IoT integration, and big data analytics platforms that optimize asset performance and extend equipment lifespan.

Integration of IoT with Condition Monitoring and Predictive Analytics

Integration of IoT with condition monitoring enables real-time data collection from sensors, enhancing equipment health tracking and fault detection. Predictive analytics processes this IoT-generated data to forecast failures and optimize maintenance schedules, reducing downtime and costs. Combining IoT, condition monitoring, and predictive analytics drives smarter asset management and operational efficiency across industries.

Challenges in Implementing Condition Monitoring vs Predictive Analytics

Implementing condition monitoring faces challenges such as high sensor costs, data integration complexities, and the need for continuous real-time data collection to detect anomalies effectively. Predictive analytics requires vast historical data sets, advanced machine learning models, and expertise in data science to accurately forecast failures, which can be resource-intensive and technically demanding. Both methods struggle with data quality issues, system interoperability, and the need for skilled personnel to interpret insights for reliable maintenance decision-making.

Future Trends in Industrial Monitoring Technologies

Condition monitoring relies on real-time data acquisition from sensors to detect equipment anomalies, whereas predictive analytics employs machine learning algorithms to forecast future failures by analyzing historical and operational data. Future trends in industrial monitoring technologies highlight the integration of AI-driven predictive maintenance platforms that improve accuracy through advanced pattern recognition and enable decentralized edge computing for faster decision-making. Emphasis on IoT connectivity and digital twins will enhance system-wide visibility, driving proactive asset management and reducing unplanned downtime.

Vibration Analysis

Vibration analysis in condition monitoring detects equipment anomalies through real-time sensor data, while predictive analytics leverages this data with machine learning algorithms to forecast potential failures and optimize maintenance schedules.

Prognostics

Condition monitoring continuously tracks equipment health using real-time data, while predictive analytics leverages historical and sensor data through advanced algorithms to perform prognostics, forecasting potential failures and remaining useful life with higher accuracy.

Reliability-Centered Maintenance

Reliability-Centered Maintenance leverages condition monitoring to collect real-time equipment data and employs predictive analytics to forecast failures, optimizing maintenance schedules and reducing unplanned downtime.

Data-driven Maintenance

Data-driven maintenance leverages condition monitoring to gather real-time equipment data and predictive analytics to forecast failures, optimizing asset performance and minimizing downtime.

Machine Health Diagnostics

Condition monitoring tracks real-time machine health data to detect anomalies, while predictive analytics uses historical and sensor data to forecast potential failures, optimizing maintenance strategies.

Fault Detection

Condition monitoring continuously tracks equipment parameters to detect faults early, while predictive analytics uses historical data and machine learning models to forecast potential faults before they occur.

Remaining Useful Life (RUL) Estimation

Predictive analytics enhances Remaining Useful Life (RUL) estimation by using condition monitoring data combined with machine learning models to forecast equipment failure more accurately.

Real-time Sensor Data Acquisition

Real-time sensor data acquisition enhances condition monitoring by continuously capturing equipment status and powers predictive analytics to forecast failures and optimize maintenance schedules accurately.

Equipment Anomaly Detection

Predictive analytics enhances equipment anomaly detection by using real-time condition monitoring data to forecast failures and optimize maintenance schedules.

Predictive Maintenance (PdM)

Predictive Maintenance (PdM) leverages Predictive Analytics using real-time data and advanced machine learning algorithms to forecast equipment failures before Condition Monitoring detects anomalies, enabling proactive maintenance and reducing unplanned downtime.

Condition monitoring vs Predictive analytics Infographic

njnir.com

njnir.com