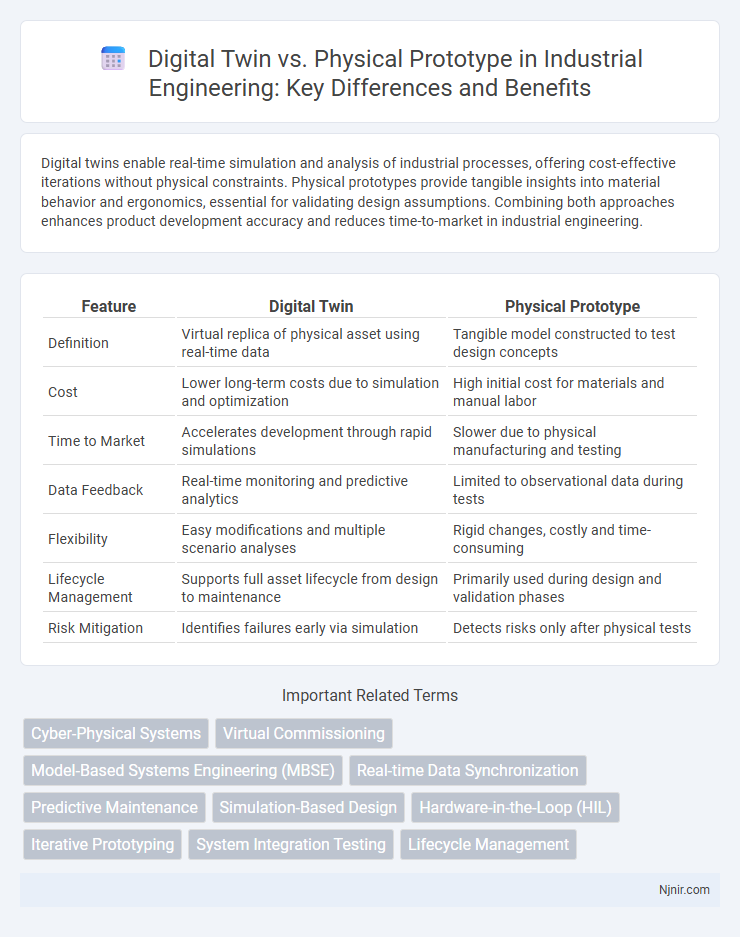

Digital twins enable real-time simulation and analysis of industrial processes, offering cost-effective iterations without physical constraints. Physical prototypes provide tangible insights into material behavior and ergonomics, essential for validating design assumptions. Combining both approaches enhances product development accuracy and reduces time-to-market in industrial engineering.

Table of Comparison

| Feature | Digital Twin | Physical Prototype |

|---|---|---|

| Definition | Virtual replica of physical asset using real-time data | Tangible model constructed to test design concepts |

| Cost | Lower long-term costs due to simulation and optimization | High initial cost for materials and manual labor |

| Time to Market | Accelerates development through rapid simulations | Slower due to physical manufacturing and testing |

| Data Feedback | Real-time monitoring and predictive analytics | Limited to observational data during tests |

| Flexibility | Easy modifications and multiple scenario analyses | Rigid changes, costly and time-consuming |

| Lifecycle Management | Supports full asset lifecycle from design to maintenance | Primarily used during design and validation phases |

| Risk Mitigation | Identifies failures early via simulation | Detects risks only after physical tests |

Introduction to Digital Twin and Physical Prototype

A digital twin is a virtual replica of a physical object or system that enables real-time monitoring, simulation, and analysis by integrating IoT sensors and data analytics. A physical prototype is an early, tangible model built to test design concepts, functionality, and feasibility through hands-on experimentation and observation. Digital twins offer continuous, dynamic insights and predictive capabilities, whereas physical prototypes provide direct, experiential validation of design ideas.

Core Differences Between Digital Twins and Physical Prototypes

Digital twins provide real-time, dynamic simulations of physical assets using sensor data, enabling continuous monitoring and predictive analytics, while physical prototypes are tangible models used for initial testing and validation of design concepts. Digital twins evolve throughout the asset's lifecycle, reflecting actual conditions and performance, whereas physical prototypes represent static, pre-production versions that require physical alteration for updates. The use of digital twins accelerates innovation and reduces costs by simulating scenarios virtually, whereas physical prototypes involve material costs and longer iteration cycles.

Advantages of Digital Twins in Industrial Engineering

Digital twins offer real-time data analytics and predictive maintenance capabilities that significantly reduce downtime and operational costs in industrial engineering. They enable virtual prototyping and testing under various conditions without material waste, accelerating design iterations and improving product quality. Enhanced monitoring through digital twins facilitates optimized resource management and boosts overall process efficiency compared to traditional physical prototypes.

Benefits and Limitations of Physical Prototyping

Physical prototyping offers tangible, real-world testing that validates product design under actual conditions, providing accurate feedback on form, fit, and function. However, it involves higher costs, longer development times, and limited flexibility for rapid iterations compared to digital twins. The physical approach may also face difficulties in simulating complex scenarios or predicting long-term performance without multiple prototype versions.

Cost Efficiency: Digital Twins vs Physical Prototypes

Digital twins significantly reduce development costs by enabling virtual testing and iteration without the need for expensive physical materials or manufacturing processes. Physical prototypes require substantial investment in raw materials, labor, and time, which can escalate project budgets and delay time-to-market. By leveraging real-time data and simulation, digital twins optimize product design and performance while minimizing waste and resource consumption.

Time-to-Market Considerations

Digital twins significantly reduce time-to-market by enabling real-time simulation, testing, and iterative design adjustments without the need for physical fabrication. Unlike physical prototypes that require manufacturing and manual evaluations, digital twins facilitate parallel development processes, accelerating validation and troubleshooting. The faster feedback loop in digital twin technology shortens product development cycles and allows quicker response to market demands.

Accuracy and Predictive Capabilities

Digital twins offer superior accuracy by continuously capturing real-time data from sensors embedded in physical systems, enabling precise simulation and analysis of performance under various conditions. Physical prototypes provide tangible insights but often lack the dynamic adaptability and detailed predictive capabilities essential for iterative design improvements. Advanced digital twin technology leverages machine learning algorithms to predict future states and potential failures, significantly enhancing proactive decision-making compared to static physical models.

Integration with Industry 4.0 Technologies

Digital twins seamlessly integrate with Industry 4.0 technologies such as IoT sensors, AI analytics, and cloud computing to enable real-time monitoring and predictive maintenance. Physical prototypes lack this continuous connectivity and data-driven feedback loop, limiting their capability for dynamic optimization during production. The synergy between digital twins and Industry 4.0 fosters enhanced automation, reduced development cycles, and improved operational efficiency.

Real-World Applications and Case Studies

Digital twins simulate real-world physical prototypes in industries like aerospace, manufacturing, and automotive, enabling predictive maintenance, design optimization, and performance monitoring. Companies such as General Electric use digital twin technology to reduce downtime by analyzing sensor data and predicting equipment failures in turbines, while automotive giants like Tesla apply digital twins for virtual crash testing and rapid prototyping. Real-world case studies demonstrate that digital twins lower costs and development time compared to traditional physical prototypes by providing continuous feedback and iteration in a virtual environment.

Future Trends: Digital Twin and Physical Prototype Collaboration

Future trends indicate a growing synergy between digital twin technology and physical prototypes, enhancing real-time data integration and predictive analytics for product development. The collaboration enables iterative design improvements by combining virtual simulations with tangible testing, reducing time-to-market and development costs. Advanced AI-driven digital twins will increasingly support physical prototype adjustments, fostering smarter, more adaptive manufacturing processes.

Cyber-Physical Systems

Digital twins in Cyber-Physical Systems enable real-time simulation, monitoring, and optimization of physical prototypes, significantly reducing development time and costs.

Virtual Commissioning

Virtual commissioning accelerates system validation by using digital twin technology to simulate and optimize automation processes before building physical prototypes.

Model-Based Systems Engineering (MBSE)

Digital twins enable continuous, real-time simulation and validation within Model-Based Systems Engineering (MBSE), surpassing traditional physical prototypes by enhancing accuracy, scalability, and lifecycle integration.

Real-time Data Synchronization

Digital twins enable real-time data synchronization with physical prototypes, allowing continuous monitoring and immediate feedback for optimized design and performance validation.

Predictive Maintenance

Digital twins enable real-time predictive maintenance by continuously analyzing sensor data to forecast equipment failures, outperforming traditional physical prototypes reliant on periodic inspections.

Simulation-Based Design

Simulation-based design using digital twins enables faster, cost-effective iterations and precise performance predictions compared to traditional physical prototypes.

Hardware-in-the-Loop (HIL)

Hardware-in-the-Loop (HIL) testing integrates digital twin simulations with physical prototypes to validate hardware performance in real-time, enhancing accuracy and reducing development costs.

Iterative Prototyping

Digital twins enable faster iterative prototyping by providing real-time simulations and feedback, reducing the need for multiple costly physical prototypes.

System Integration Testing

Digital twins enable comprehensive system integration testing by simulating real-world interactions and operational conditions, reducing the time and cost compared to traditional physical prototypes.

Lifecycle Management

Digital twins enable real-time lifecycle management with continuous data synchronization and predictive maintenance, surpassing the static insights of physical prototypes.

Digital twin vs Physical prototype Infographic

njnir.com

njnir.com