Single Minute Exchange of Die (SMED) is a methodology specifically designed to reduce setup times in manufacturing processes to less than ten minutes, emphasizing the separation of internal and external setup tasks. Quick Changeover refers to the broader practice of minimizing downtime during equipment changeovers, which may or may not apply SMED principles. Implementing SMED within quick changeover strategies significantly enhances operational efficiency by streamlining transitions and increasing machine availability.

Table of Comparison

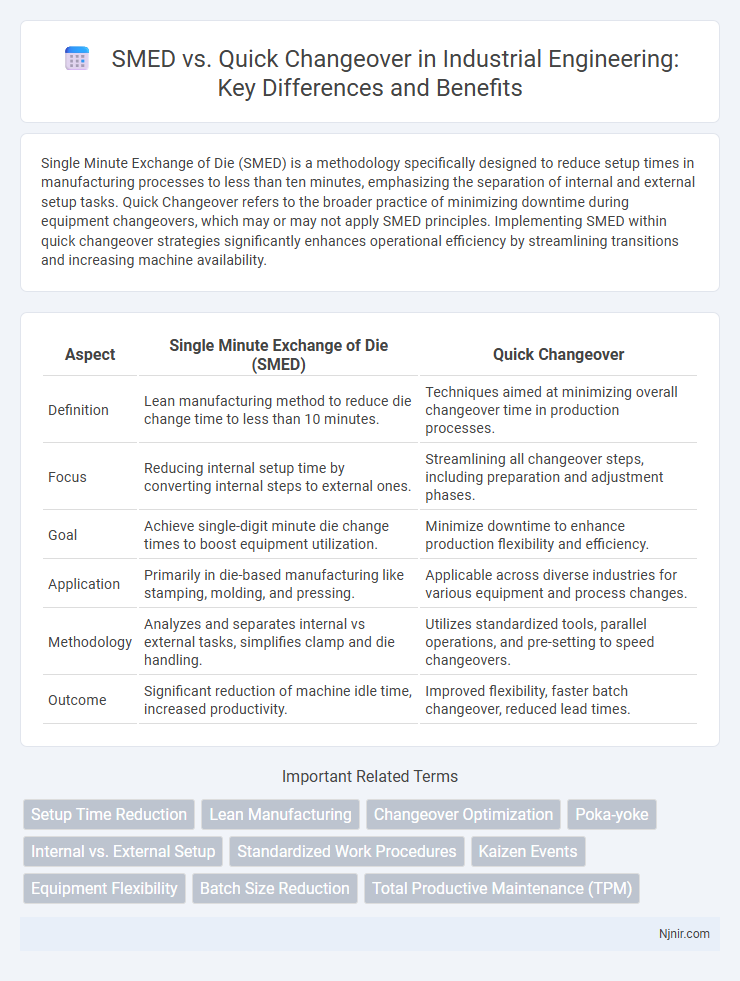

| Aspect | Single Minute Exchange of Die (SMED) | Quick Changeover |

|---|---|---|

| Definition | Lean manufacturing method to reduce die change time to less than 10 minutes. | Techniques aimed at minimizing overall changeover time in production processes. |

| Focus | Reducing internal setup time by converting internal steps to external ones. | Streamlining all changeover steps, including preparation and adjustment phases. |

| Goal | Achieve single-digit minute die change times to boost equipment utilization. | Minimize downtime to enhance production flexibility and efficiency. |

| Application | Primarily in die-based manufacturing like stamping, molding, and pressing. | Applicable across diverse industries for various equipment and process changes. |

| Methodology | Analyzes and separates internal vs external tasks, simplifies clamp and die handling. | Utilizes standardized tools, parallel operations, and pre-setting to speed changeovers. |

| Outcome | Significant reduction of machine idle time, increased productivity. | Improved flexibility, faster batch changeover, reduced lead times. |

Introduction to Single Minute Exchange of Die (SMED) and Quick Changeover

Single Minute Exchange of Die (SMED) is a lean manufacturing methodology designed to reduce equipment setup times to less than 10 minutes, enhancing production efficiency and minimizing downtime. Quick Changeover refers to techniques focused on expediting the process of switching from one product or operation to another, thereby optimizing machine availability and flexibility. Both SMED and Quick Changeover aim to streamline manufacturing transitions, but SMED emphasizes systematic reduction of internal and external setup activities through standardized procedures and tool organization.

Historical Background and Development

Single Minute Exchange of Die (SMED) was developed by Shigeo Shingo in the 1950s as a systematic method to reduce equipment setup times to under 10 minutes, revolutionizing manufacturing efficiency. Quick Changeover originated as a broader concept in lean manufacturing aimed at minimizing changeover time but lacked the refined step-by-step framework of SMED until Shingo's contributions. The evolution of SMED built on early quick changeover practices, formalizing principles that enabled mass production with minimal downtime.

Defining SMED and Quick Changeover: Terminology and Key Concepts

Single Minute Exchange of Die (SMED) is a lean manufacturing methodology aimed at reducing equipment setup times to less than 10 minutes, focusing on separating internal and external setup tasks for faster process changeovers. Quick Changeover refers to the broader strategy of minimizing downtime during transitions between production runs by streamlining setup activities, encompassing techniques such as standardization, preparation, and simplified adjustments. SMED is a specific approach within Quick Changeover practices that emphasizes rapid die changes through detailed analysis and optimization of setup operations.

The Core Objectives: Reducing Downtime and Improving Flexibility

Single Minute Exchange of Die (SMED) and Quick Changeover both aim to minimize machine downtime by streamlining setup processes, enhancing production flexibility. SMED specifically targets reducing internal setup time to under 10 minutes, transforming tasks to external setup whenever possible to maximize operational efficiency. Quick Changeover emphasizes rapid transitions between jobs, enabling manufacturers to adapt swiftly to varying product demands and improve overall equipment effectiveness (OEE).

Step-by-Step Process: SMED Methodology Explained

The Single Minute Exchange of Die (SMED) methodology emphasizes separating internal and external setup activities to reduce changeover time to under 10 minutes. Its step-by-step process includes identifying all setup tasks, converting internal tasks to external ones, streamlining all operations, and standardizing the procedure for efficiency. This contrasted approach to general Quick Changeover focuses on detailed analysis and systematic elimination of waste in every setup step to maximize productivity and minimize downtime.

Quick Changeover Techniques: Tools and Best Practices

Quick Changeover techniques streamline equipment setups by minimizing downtime through standardized processes, use of specialized tools like modular fixtures, and implementation of parallel operations. Best practices include thorough planning, detailed setup checklists, and continuous operator training to ensure swift and error-free transitions. Incorporating advanced measurement tools and 5S workplace organization enhances efficiency, supporting lean manufacturing goals.

Comparing SMED and Quick Changeover: Similarities and Differences

Single Minute Exchange of Die (SMED) and Quick Changeover both aim to reduce machine setup times, enhancing production efficiency and flexibility. SMED specifically targets reducing changeover times to less than 10 minutes by separating internal and external setup tasks, while Quick Changeover broadly refers to any method that accelerates equipment switching without a strict time threshold. Both methodologies share principles like standardization and streamlining steps, but SMED provides a structured, phased approach focused on rapid die changes, distinguishing it from the more generic Quick Changeover concept.

Implementation Challenges and Solutions

Single Minute Exchange of Die (SMED) and Quick Changeover both aim to reduce equipment setup times but face implementation challenges such as resistance to change, lack of standardized procedures, and inadequate employee training. Overcoming these obstacles requires comprehensive process mapping, workforce engagement through hands-on training, and the use of detailed standard operating procedures (SOPs) to ensure consistency and repeatability. Continuous improvement initiatives like Kaizen events and real-time performance monitoring accelerate adaptation and reinforce the change management process.

Real-World Case Studies in Industrial Engineering

Single Minute Exchange of Die (SMED) significantly reduces setup times by separating internal and external setup activities, as demonstrated in Toyota's automotive assembly lines where changeover times dropped from hours to under 10 minutes, boosting production flexibility. Quick Changeover, a broader methodology, emphasizes minimizing downtime through standardized tools and procedures, exemplified by Bosch's manufacturing plants achieving 50% faster machine setups without extensive equipment modification. Both approaches enhance Lean manufacturing by increasing throughput and reducing waste, with real-world case studies highlighting that integrating SMED principles into Quick Changeover processes yields optimal efficiency gains in industrial engineering.

Measuring the Impact: Performance Metrics and Continuous Improvement

Single Minute Exchange of Die (SMED) and Quick Changeover both aim to minimize downtime, but SMED specifically targets reducing setup times to under 10 minutes through standardized steps and external preparation. Performance metrics such as setup time reduction, equipment utilization rate, and overall equipment effectiveness (OEE) provide quantitative measures to evaluate impact. Continuous improvement processes leverage these metrics to identify bottlenecks, optimize workflows, and further streamline changeovers for sustained operational efficiency.

Setup Time Reduction

Single Minute Exchange of Die (SMED) reduces setup time by systematically separating internal and external setup tasks to achieve changeovers under 10 minutes, while Quick Changeover broadly aims to minimize setup duration but lacks SMED's structured methodology for rapid transformation.

Lean Manufacturing

Single Minute Exchange of Die (SMED) in Lean Manufacturing specifically targets reducing equipment setup times to under 10 minutes, whereas Quick Changeover encompasses broader strategies for minimizing production downtime and increasing operational efficiency.

Changeover Optimization

Single Minute Exchange of Die (SMED) focuses on minimizing changeover times to under 10 minutes by separating internal and external tasks, while Quick Changeover aims at overall changeover optimization using various techniques to reduce equipment downtime and enhance production efficiency.

Poka-yoke

Single Minute Exchange of Die (SMED) improves Quick Changeover efficiency by implementing Poka-yoke techniques that prevent errors and ensure mistake-proof setups.

Internal vs. External Setup

Single Minute Exchange of Die (SMED) minimizes internal setup time by converting it into external setup tasks that can be performed while the machine is running, whereas Quick Changeover primarily emphasizes reducing overall setup time without explicitly differentiating between internal and external activities.

Standardized Work Procedures

Single Minute Exchange of Die (SMED) and Quick Changeover both prioritize reducing setup time by implementing standardized work procedures that streamline tasks, minimize waste, and enhance efficiency in manufacturing processes.

Kaizen Events

Kaizen events in Single Minute Exchange of Die (SMED) prioritize reducing setup times under 10 minutes by systematically separating internal and external tasks, whereas Quick Changeover emphasizes overall process efficiency improvements without strictly time-defined targets.

Equipment Flexibility

Single Minute Exchange of Die (SMED) enhances equipment flexibility by minimizing setup times to less than 10 minutes, whereas Quick Changeover broadly aims to reduce downtime without a strict time target, making SMED a more precise methodology for agile manufacturing adjustments.

Batch Size Reduction

Single Minute Exchange of Die (SMED) significantly reduces batch size by minimizing setup times through standardized, streamlined processes, enabling faster changeovers compared to traditional Quick Changeover methods.

Total Productive Maintenance (TPM)

SMED, a core TPM technique, minimizes equipment changeover time under 10 minutes, enhancing Quick Changeover efficiency by reducing downtime, boosting productivity, and enabling lean manufacturing.

Single Minute Exchange of Die (SMED) vs Quick Changeover Infographic

njnir.com

njnir.com