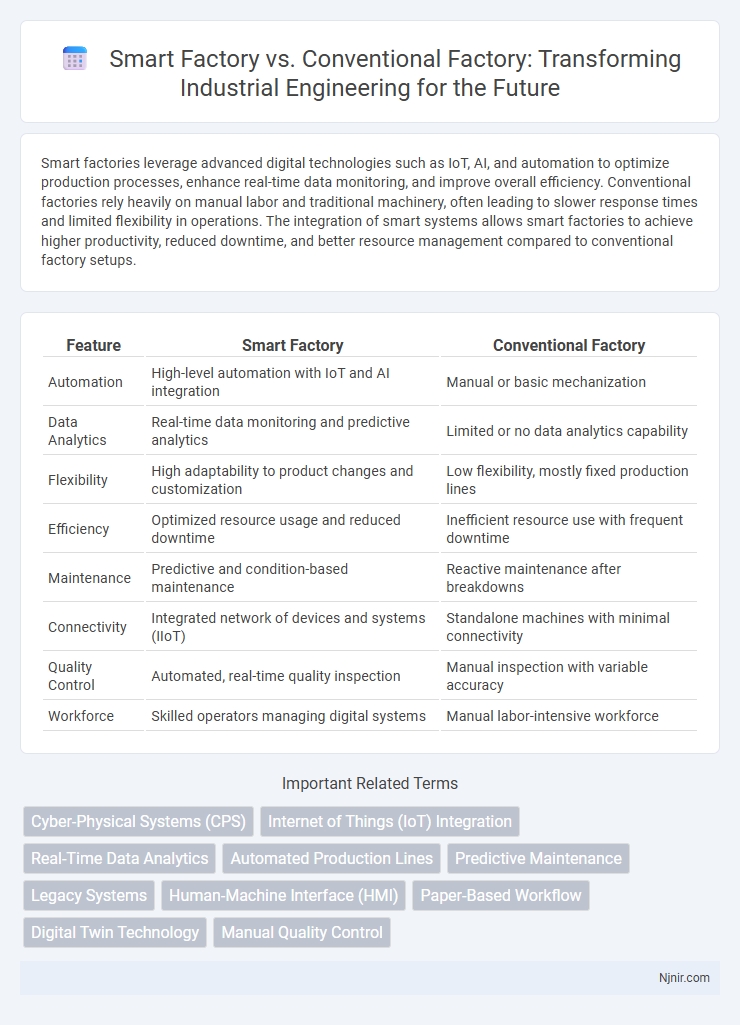

Smart factories leverage advanced digital technologies such as IoT, AI, and automation to optimize production processes, enhance real-time data monitoring, and improve overall efficiency. Conventional factories rely heavily on manual labor and traditional machinery, often leading to slower response times and limited flexibility in operations. The integration of smart systems allows smart factories to achieve higher productivity, reduced downtime, and better resource management compared to conventional factory setups.

Table of Comparison

| Feature | Smart Factory | Conventional Factory |

|---|---|---|

| Automation | High-level automation with IoT and AI integration | Manual or basic mechanization |

| Data Analytics | Real-time data monitoring and predictive analytics | Limited or no data analytics capability |

| Flexibility | High adaptability to product changes and customization | Low flexibility, mostly fixed production lines |

| Efficiency | Optimized resource usage and reduced downtime | Inefficient resource use with frequent downtime |

| Maintenance | Predictive and condition-based maintenance | Reactive maintenance after breakdowns |

| Connectivity | Integrated network of devices and systems (IIoT) | Standalone machines with minimal connectivity |

| Quality Control | Automated, real-time quality inspection | Manual inspection with variable accuracy |

| Workforce | Skilled operators managing digital systems | Manual labor-intensive workforce |

Overview of Smart Factories and Conventional Factories

Smart factories utilize advanced technologies such as IoT, AI, and automation to enhance production efficiency, reduce costs, and enable real-time data monitoring, contrasting with conventional factories that rely on manual labor and traditional machinery with limited connectivity. Conventional factories often face challenges like slower response times, higher error rates, and less flexibility in production processes. In contrast, smart factories offer improved scalability, predictive maintenance, and greater adaptability to market demands through integrated digital systems.

Core Technologies in Smart Factories

Smart factories leverage advanced core technologies such as the Internet of Things (IoT), artificial intelligence (AI), and robotics to enable real-time data analytics, automation, and predictive maintenance. These technologies enhance operational efficiency, flexibility, and accuracy compared to conventional factories that rely heavily on manual processes and isolated machinery. Integration of digital twins and cloud computing further distinguishes smart factories by enabling continuous monitoring and optimization of production systems.

Workflow and Process Automation Comparison

Smart factories leverage advanced robotics, IoT sensors, and AI-driven analytics to automate workflows, resulting in real-time data integration and adaptive process control. Conventional factories rely heavily on manual labor and fixed automation systems, leading to less flexibility and slower response times in production management. The enhanced process automation in smart factories reduces human error, increases efficiency, and enables predictive maintenance, surpassing the capabilities of traditional factory setups.

Data Management and Real-Time Analytics

Smart factories leverage advanced data management systems and real-time analytics to optimize production processes, enabling predictive maintenance and minimizing downtime. Conventional factories typically rely on manual data entry and batch processing, resulting in delayed decision-making and less efficient operations. The integration of IoT sensors and AI-driven analytics in smart factories ensures continuous monitoring and dynamic adjustment, vastly improving operational efficiency compared to traditional setups.

Flexibility and Scalability in Production

Smart factories leverage advanced technologies like IoT, AI, and robotics to enhance flexibility, enabling rapid adaptation to changing production demands and customized orders. Conventional factories often rely on rigid processes and fixed machinery, limiting their ability to scale or adjust production efficiently. The scalability of smart factories allows seamless integration of new equipment or production lines, minimizing downtime and boosting responsiveness compared to traditional manufacturing setups.

Labor Force: Human Intervention vs Automation

Smart factories leverage advanced automation technologies, significantly reducing human intervention by utilizing robotics, IoT, and AI to enhance productivity and minimize errors. Conventional factories rely heavily on manual labor, with workers performing repetitive and physically demanding tasks, leading to higher risks of inefficiencies and workplace injuries. The shift from human-centric operations to automated processes in smart factories enables real-time data monitoring, predictive maintenance, and increased customization capabilities.

Energy Efficiency and Resource Optimization

Smart factories leverage advanced IoT sensors, AI-driven analytics, and automated machinery to significantly reduce energy consumption and optimize resource utilization compared to conventional factories, which rely on manual monitoring and less integrated systems. Energy management systems in smart factories enable real-time monitoring and adaptive control, cutting waste and improving operational efficiency by up to 30%. Resource optimization is enhanced through predictive maintenance and supply chain integration, minimizing raw material usage and downtime that are common in traditional manufacturing setups.

Quality Control and Predictive Maintenance

Smart factories leverage IoT sensors and real-time data analytics to enhance quality control by detecting defects early and ensuring consistent production standards, outperforming conventional factories that rely on manual inspections often prone to human error. Predictive maintenance in smart factories utilizes machine learning algorithms to predict equipment failures before downtime occurs, reducing maintenance costs and unplanned stoppages compared to traditional scheduled maintenance approaches in conventional factories. This integration of AI-driven quality control and predictive maintenance systems results in higher operational efficiency and product reliability.

Cost Implications: Initial Investment and Operational Expenses

Smart factories require a significantly higher initial investment due to advanced technologies like IoT sensors, AI-driven automation, and robotics, which can cost millions of dollars to implement. Operational expenses in smart factories tend to be lower over time because automated processes reduce labor costs and increase energy efficiency, leading to substantial savings in maintenance and downtime. Conventional factories have lower upfront costs but face higher ongoing expenses related to manual labor, lower productivity, and more frequent equipment failures.

Future Trends and Industrial Adaptation

Smart factories leverage advanced technologies like IoT, AI, and robotics to enable real-time data analytics, predictive maintenance, and enhanced automation, significantly outperforming conventional factories in efficiency and flexibility. Future trends emphasize integration of edge computing, digital twins, and 5G connectivity to further optimize production processes and enable adaptive manufacturing ecosystems. Industrial adaptation requires investment in workforce reskilling, cybersecurity measures, and seamless interoperability between legacy systems and new smart technologies to maintain competitiveness in the evolving market.

Cyber-Physical Systems (CPS)

Smart factories leverage Cyber-Physical Systems (CPS) to enable real-time data integration, automation, and adaptive control, unlike conventional factories that rely on isolated mechanical processes without interconnected digital feedback.

Internet of Things (IoT) Integration

Smart factories utilize Internet of Things (IoT) integration to enable real-time data monitoring, predictive maintenance, and automated decision-making, vastly improving efficiency compared to conventional factories.

Real-Time Data Analytics

Smart factories leverage real-time data analytics to optimize production efficiency, reduce downtime, and enhance quality control, whereas conventional factories rely on delayed or manual data processing, limiting responsiveness and decision-making accuracy.

Automated Production Lines

Smart factories utilize automated production lines equipped with IoT sensors and AI-driven robots to enhance efficiency, reduce errors, and enable real-time data analytics, whereas conventional factories rely on manual or semi-automated processes with limited connectivity and slower response times.

Predictive Maintenance

Smart factories utilize advanced sensors and AI-driven predictive maintenance to minimize unplanned downtime, whereas conventional factories rely on scheduled maintenance that often leads to higher operational costs and equipment failures.

Legacy Systems

Smart factories integrate advanced digital technologies that replace legacy systems in conventional factories, significantly enhancing automation, data analytics, and operational efficiency.

Human-Machine Interface (HMI)

Smart factories utilize advanced Human-Machine Interface (HMI) technologies with real-time data visualization and AI-driven analytics, enhancing operator efficiency and decision-making compared to conventional factories relying on basic, manual controls.

Paper-Based Workflow

Smart factories eliminate paper-based workflow with integrated digital systems, boosting efficiency and reducing errors compared to conventional factories reliant on manual documentation.

Digital Twin Technology

Smart factories leverage Digital Twin technology to create real-time virtual replicas of physical assets, enabling predictive maintenance and optimized production, whereas conventional factories lack such advanced simulation and real-time monitoring capabilities.

Manual Quality Control

Smart factories enhance manual quality control through real-time data analytics and automated feedback, significantly reducing human error compared to conventional factories reliant solely on manual inspection.

Smart Factory vs Conventional Factory Infographic

njnir.com

njnir.com