Labor productivity measures the output generated per worker within a given time frame, emphasizing human efficiency and skill application. Machine productivity quantifies the output produced by machinery, highlighting automation, speed, and precision advantages. Balancing labor and machine productivity is essential for optimizing industrial processes and maximizing overall operational efficiency.

Table of Comparison

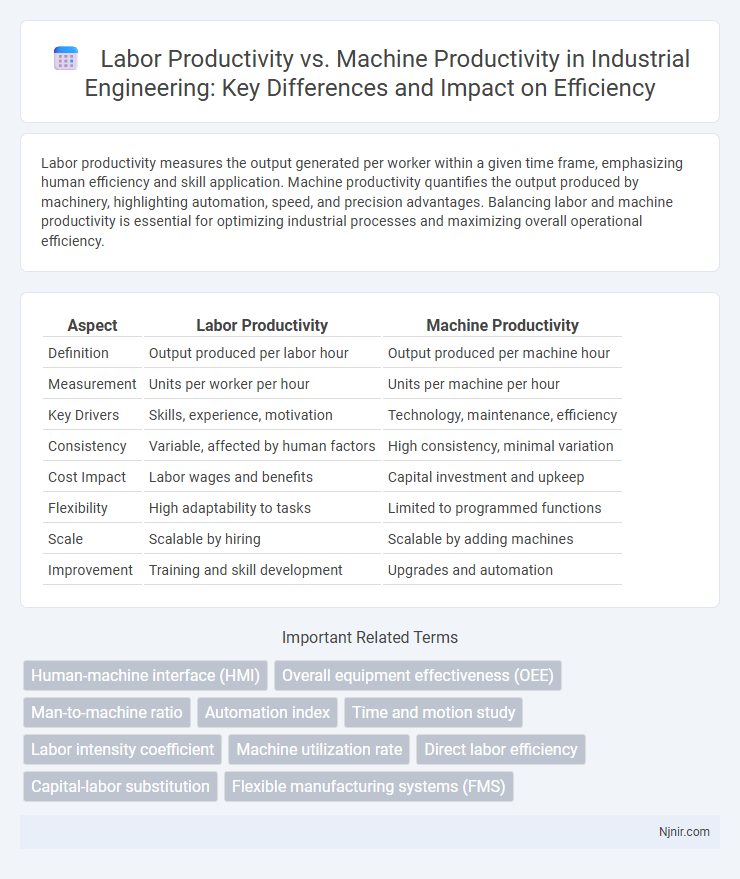

| Aspect | Labor Productivity | Machine Productivity |

|---|---|---|

| Definition | Output produced per labor hour | Output produced per machine hour |

| Measurement | Units per worker per hour | Units per machine per hour |

| Key Drivers | Skills, experience, motivation | Technology, maintenance, efficiency |

| Consistency | Variable, affected by human factors | High consistency, minimal variation |

| Cost Impact | Labor wages and benefits | Capital investment and upkeep |

| Flexibility | High adaptability to tasks | Limited to programmed functions |

| Scale | Scalable by hiring | Scalable by adding machines |

| Improvement | Training and skill development | Upgrades and automation |

Defining Labor Productivity in Industrial Engineering

Labor productivity in industrial engineering measures the output produced per labor hour, emphasizing workforce efficiency in manufacturing processes. Unlike machine productivity, which evaluates the output of equipment and automation systems, labor productivity focuses on human resource capabilities and their contribution to overall production. Optimizing labor productivity involves improving worker skills, minimizing downtime, and streamlining workflows to enhance operational performance.

Understanding Machine Productivity

Machine productivity measures the efficiency of automated equipment in producing goods within a specific timeframe, highlighting factors such as cycle time, uptime, and output quality. Unlike labor productivity, which depends on human effort and skill, machine productivity focuses on maximizing throughput and minimizing downtime through maintenance and technological upgrades. Understanding machine productivity enables businesses to optimize manufacturing processes, reduce costs, and enhance overall production capacity.

Key Metrics to Measure Productivity

Labor productivity is primarily measured by output per labor hour, emphasizing metrics such as units produced per worker and value added per employee. Machine productivity focuses on output per machine hour, highlighting operational efficiency metrics like machine utilization rate, cycle time, and overall equipment effectiveness (OEE). Combining labor and machine productivity metrics provides a comprehensive view of operational performance and resource optimization.

Comparative Analysis: Labor vs Machine Output

Labor productivity, measured by output per worker per hour, varies significantly across industries due to skill level, technological access, and work environment. Machine productivity, often quantified by output per machine hour or unit, consistently outperforms labor in repetitive and high-precision tasks, driven by automation, minimal downtime, and consistent quality. Comparative analysis reveals machines excel in large-scale manufacturing, while labor remains critical for complex decision-making, customization, and adaptability in dynamic environments.

Factors Influencing Labor Productivity

Labor productivity is influenced by factors such as worker skills, training, motivation, and ergonomics in the workplace, while machine productivity depends on technology, maintenance, and operational efficiency. Human factors including experience, teamwork, and workplace environment directly affect labor output per hour, contrasting with machines where uptime and automation level are critical. Investment in employee development and process optimization enhances labor productivity, distinguishing it from the primarily technical determinants of machine productivity.

Factors Impacting Machine Productivity

Machine productivity is affected by factors such as equipment efficiency, maintenance frequency, and technological advancements that enable faster processing speeds. Environmental conditions, including temperature and humidity, also influence machine performance and output quality. Operator skill and software integration play critical roles in maximizing the utilization and productivity of machinery in industrial settings.

Cost-Benefit Analysis: Human Labor vs Automation

Labor productivity measures output per worker, while machine productivity gauges output per machine, crucial for cost-benefit analysis in automation decisions. Human labor offers flexibility and problem-solving skills, yet automation reduces labor costs, increases consistency, and minimizes errors over time. Balancing initial capital investment in machinery against long-term savings in wages and improved production efficiency determines the optimal mix for maximizing returns.

Technological Advancements Shaping Productivity

Technological advancements such as automation, artificial intelligence, and machine learning have significantly enhanced machine productivity by enabling faster, more precise operations with minimal human intervention. These innovations allow machines to perform complex tasks continuously, increasing output rates and reducing errors compared to traditional labor-intensive methods. While labor productivity benefits from digital tools and ergonomic improvements, the rapid evolution of smart manufacturing technologies predominantly drives the surge in overall productivity through optimized machine performance.

Strategies for Balancing Labor and Machine Efficiency

Balancing labor productivity with machine productivity requires implementing strategies such as workflow optimization, where tasks are allocated based on the strengths of human workers and automated systems to maximize overall output. Incorporating real-time data analytics enables continuous monitoring and adjustment of both labor and machine performance, ensuring efficiency without overburdening either resource. Investing in employee training and advanced maintenance protocols enhances synergy between workers and machines, driving higher productivity and reducing downtime.

Future Trends in Industrial Productivity Optimization

Future trends in industrial productivity optimization emphasize the integration of advanced AI and IoT technologies to enhance both labor and machine productivity. Digital twin technology and predictive analytics enable real-time monitoring and maintenance, reducing downtime and boosting machine efficiency while supporting human workers with augmented reality tools for better decision-making. Workforce upskilling combined with automation fosters a collaborative environment, maximizing output through optimized human-machine synergy.

Human-machine interface (HMI)

Optimizing Labor productivity through advanced Human-Machine Interface (HMI) enhances Machine productivity by improving operator interaction, reducing errors, and accelerating task completion.

Overall equipment effectiveness (OEE)

Overall Equipment Effectiveness (OEE) measures machine productivity by assessing availability, performance, and quality factors, whereas labor productivity evaluates human output efficiency, highlighting critical areas to optimize manufacturing operations.

Man-to-machine ratio

Labor productivity decreases as the man-to-machine ratio increases, highlighting the need to optimize this ratio for maximizing overall machine productivity.

Automation index

The automation index measures the extent to which machine productivity surpasses labor productivity by quantifying the integration of automated technologies in production processes.

Time and motion study

Time and motion studies reveal that labor productivity improves through ergonomic task design, while machine productivity hinges on minimizing downtime and optimizing cycle time.

Labor intensity coefficient

The labor intensity coefficient measures the ratio of labor input to machine output, highlighting how labor productivity inversely relates to machine productivity in industrial operations.

Machine utilization rate

Machine utilization rate directly impacts machine productivity by maximizing operational output and minimizing idle time compared to labor productivity, which is limited by human factors such as fatigue and skill variability.

Direct labor efficiency

Direct labor efficiency measures the output produced per hour of human labor, highlighting labor productivity differences compared to machine productivity, which quantifies output per machine operation hour.

Capital-labor substitution

Capital-labor substitution enhances machine productivity by allowing increased automation to replace labor, thereby improving overall labor productivity through more efficient resource allocation.

Flexible manufacturing systems (FMS)

Flexible manufacturing systems (FMS) significantly enhance machine productivity by automating complex tasks and optimizing workflow, thereby surpassing traditional labor productivity through reduced human error and increased operational efficiency.

Labor productivity vs Machine productivity Infographic

njnir.com

njnir.com