Lean manufacturing emphasizes waste reduction and process flow improvement to enhance efficiency, while Six Sigma focuses on minimizing defects through statistical analysis and quality control. Integrating both methodologies creates a robust framework for operational excellence and continuous improvement. Companies adopting this combined approach achieve higher productivity, reduced costs, and improved customer satisfaction.

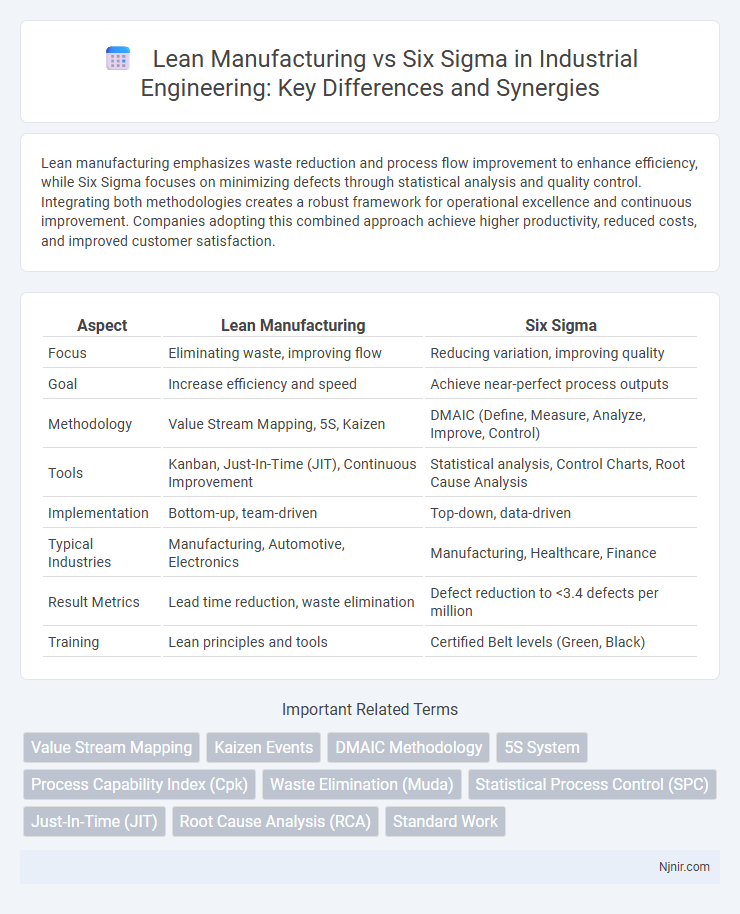

Table of Comparison

| Aspect | Lean Manufacturing | Six Sigma |

|---|---|---|

| Focus | Eliminating waste, improving flow | Reducing variation, improving quality |

| Goal | Increase efficiency and speed | Achieve near-perfect process outputs |

| Methodology | Value Stream Mapping, 5S, Kaizen | DMAIC (Define, Measure, Analyze, Improve, Control) |

| Tools | Kanban, Just-In-Time (JIT), Continuous Improvement | Statistical analysis, Control Charts, Root Cause Analysis |

| Implementation | Bottom-up, team-driven | Top-down, data-driven |

| Typical Industries | Manufacturing, Automotive, Electronics | Manufacturing, Healthcare, Finance |

| Result Metrics | Lead time reduction, waste elimination | Defect reduction to <3.4 defects per million |

| Training | Lean principles and tools | Certified Belt levels (Green, Black) |

Introduction to Lean Manufacturing and Six Sigma

Lean Manufacturing emphasizes eliminating waste and optimizing workflow to enhance production efficiency. Six Sigma focuses on reducing process variation and improving quality through data-driven methodologies and statistical analysis. Both strategies aim to improve overall operational performance but differ in their primary approaches and tools.

Historical Background and Evolution

Lean manufacturing originated from the Toyota Production System in the late 1940s, emphasizing waste reduction and continuous improvement to enhance efficiency. Six Sigma was developed by Motorola in the 1980s, focusing on reducing process variation and improving quality through statistical methods. Over time, both methodologies evolved and integrated principles, shaping modern operational excellence strategies globally.

Core Principles: Lean vs. Six Sigma

Lean manufacturing emphasizes waste reduction through continuous flow and just-in-time production to enhance efficiency and eliminate non-value-added activities. Six Sigma focuses on reducing process variation and defects by using statistical methods and DMAIC (Define, Measure, Analyze, Improve, Control) to ensure quality and consistency. Both methodologies complement each other but differ in core principles, with Lean targeting speed and efficiency and Six Sigma prioritizing precision and defect reduction.

Key Tools and Techniques

Lean manufacturing employs value stream mapping, 5S, and Kaizen events to eliminate waste and improve workflow efficiency, emphasizing continuous improvement and reducing cycle times. Six Sigma utilizes DMAIC methodology, statistical process control (SPC), and root cause analysis to reduce process variability and defects, targeting near-perfect quality outcomes. Both methodologies often integrate tools like Pareto charts and cause-and-effect diagrams to enhance problem-solving and decision-making in manufacturing environments.

Benefits of Implementing Lean Manufacturing

Implementing Lean Manufacturing enhances operational efficiency by minimizing waste and streamlining processes, which leads to reduced production costs and faster delivery times. It improves product quality through continuous improvement and real-time problem-solving, increasing customer satisfaction and market competitiveness. Lean principles also foster a culture of employee engagement and collaboration, driving sustained innovation and long-term business growth.

Advantages of Six Sigma Methodology

Six Sigma methodology offers significant advantages, including a data-driven approach that reduces process variation and improves product quality by targeting defects at a statistical level. Its focus on measurable financial results ensures cost savings and increased customer satisfaction through systematic problem-solving tools such as DMAIC (Define, Measure, Analyze, Improve, Control). Six Sigma projects often lead to sustainable improvements and enhanced process control, making it ideal for organizations aiming for precision and efficiency in complex production environments.

Comparing Problem-Solving Approaches

Lean manufacturing emphasizes waste reduction through continuous flow and eliminating non-value-added activities, focusing on visual management and quick problem resolution. Six Sigma utilizes a data-driven, statistical approach with DMAIC (Define, Measure, Analyze, Improve, Control) methodology to identify and eliminate defects, prioritizing process variation reduction. Combining both methodologies enhances quality improvement by integrating Lean's efficiency with Six Sigma's precision analysis.

Real-World Applications in Industry

Lean manufacturing drives efficiency by eliminating waste and streamlining processes, widely adopted in automotive giants like Toyota to enhance production flow and reduce lead times. Six Sigma focuses on reducing variation and improving quality through data-driven methodologies, embraced by companies such as General Electric to minimize defects and boost customer satisfaction. Many industries integrate both approaches, leveraging Lean's speed and Six Sigma's precision to optimize overall operational performance.

Integrating Lean and Six Sigma (Lean Six Sigma)

Integrating Lean and Six Sigma creates Lean Six Sigma, a methodology that combines Lean's waste reduction techniques with Six Sigma's focus on reducing process variation. Lean Six Sigma enhances operational efficiency by streamlining workflows while maintaining high quality and minimizing defects. Organizations implementing Lean Six Sigma achieve significant cost savings, improved customer satisfaction, and measurable process improvements across diverse industries.

Choosing the Right Approach for Your Organization

Choosing the right approach between Lean manufacturing and Six Sigma depends on your organization's primary goals: Lean emphasizes waste reduction and process flow improvement, while Six Sigma focuses on reducing variability and defects through data-driven analysis. Organizations aiming to enhance efficiency and speed often benefit more from Lean principles, whereas those targeting quality improvement and defect reduction may find Six Sigma more effective. Integrating both methodologies, known as Lean Six Sigma, can offer a balanced strategy, leveraging waste elimination alongside rigorous quality control to optimize overall performance.

Value Stream Mapping

Value Stream Mapping in Lean Manufacturing visualizes and eliminates waste to streamline processes, while in Six Sigma it identifies process variations to improve quality and efficiency.

Kaizen Events

Kaizen Events in Lean Manufacturing emphasize rapid, continuous improvement through focused team activities to eliminate waste, while Six Sigma applies data-driven problem-solving techniques to reduce process variation.

DMAIC Methodology

DMAIC methodology in Six Sigma emphasizes Define, Measure, Analyze, Improve, and Control steps to systematically reduce defects and variability, while lean manufacturing focuses on eliminating waste and improving process flow for efficiency.

5S System

The 5S System in lean manufacturing emphasizes workplace organization and efficiency through Sort, Set in order, Shine, Standardize, and Sustain, while Six Sigma focuses on reducing process variation and defects using data-driven methodologies.

Process Capability Index (Cpk)

Six Sigma achieves higher Process Capability Index (Cpk) values by reducing process variation and defects, whereas Lean Manufacturing focuses on eliminating waste to improve overall process efficiency without directly targeting Cpk improvement.

Waste Elimination (Muda)

Lean manufacturing focuses on waste elimination (Muda) by streamlining processes and removing non-value-added activities, while Six Sigma targets waste reduction by minimizing process variation and defects to improve quality.

Statistical Process Control (SPC)

Lean manufacturing enhances efficiency by eliminating waste, while Six Sigma emphasizes Statistical Process Control (SPC) to monitor process variation and improve quality through data-driven decision-making.

Just-In-Time (JIT)

Lean manufacturing emphasizes Just-In-Time (JIT) to minimize waste and inventory by producing only what is needed when it is needed, while Six Sigma focuses on reducing process variation and defects to improve quality and efficiency.

Root Cause Analysis (RCA)

Lean manufacturing uses Root Cause Analysis (RCA) to eliminate process waste and improve flow, while Six Sigma applies RCA to identify and reduce process variation for enhancing quality control.

Standard Work

Lean manufacturing emphasizes Standard Work as a foundation for minimizing waste through consistent processes, while Six Sigma uses Standard Work to control variability and improve quality.

lean manufacturing vs six sigma Infographic

njnir.com

njnir.com