DMAIC and DMADV are Six Sigma methodologies used for process improvement and design respectively. DMAIC focuses on improving existing processes through five phases: Define, Measure, Analyze, Improve, and Control, while DMADV is tailored for creating new processes or products with a focus on Define, Measure, Analyze, Design, and Verify. Selecting the appropriate approach depends on whether the goal is to enhance current operations or develop innovative solutions within industrial engineering.

Table of Comparison

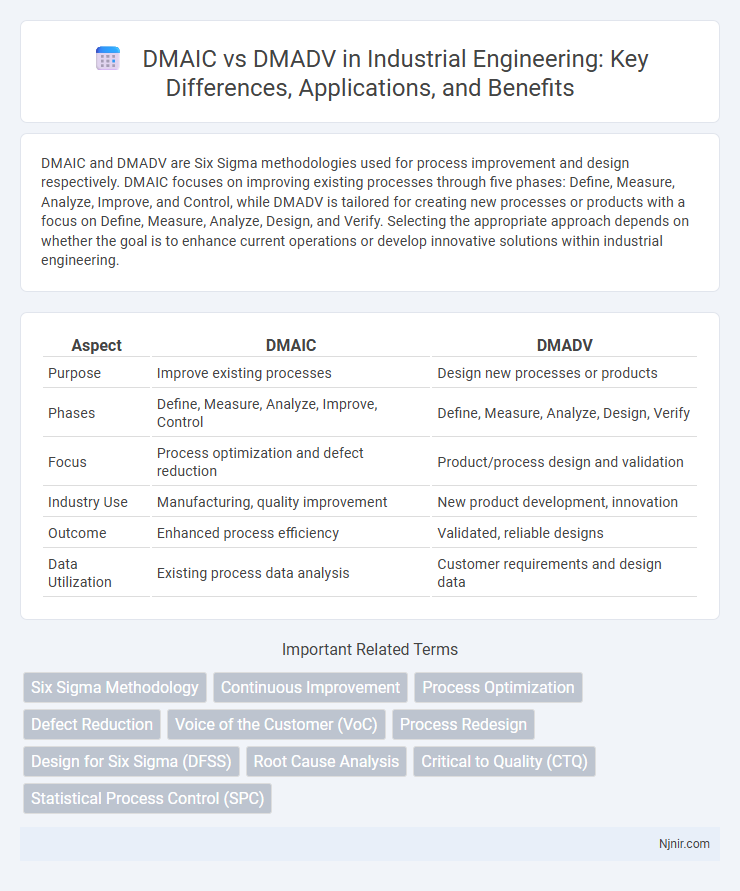

| Aspect | DMAIC | DMADV |

|---|---|---|

| Purpose | Improve existing processes | Design new processes or products |

| Phases | Define, Measure, Analyze, Improve, Control | Define, Measure, Analyze, Design, Verify |

| Focus | Process optimization and defect reduction | Product/process design and validation |

| Industry Use | Manufacturing, quality improvement | New product development, innovation |

| Outcome | Enhanced process efficiency | Validated, reliable designs |

| Data Utilization | Existing process data analysis | Customer requirements and design data |

Introduction to DMAIC and DMADV

DMAIC (Define, Measure, Analyze, Improve, Control) is a data-driven quality strategy used for improving existing processes by identifying and eliminating defects. DMADV (Define, Measure, Analyze, Design, Verify) focuses on designing new processes or products to meet customer needs and achieve high quality from the start. Both methodologies are integral to Six Sigma but serve distinct purposes in process improvement and product development.

Understanding the DMAIC Methodology

DMAIC methodology, a core component of Six Sigma, emphasizes improving existing processes through five phases: Define, Measure, Analyze, Improve, and Control. It relies on data-driven decision-making to identify defects, analyze root causes, implement improvements, and sustain process control. DMAIC contrasts with DMADV, which is used primarily for designing new processes or products, focusing on Define, Measure, Analyze, Design, and Verify stages.

Exploring the DMADV Framework

The DMADV framework, essential for designing new processes or products, stands for Define, Measure, Analyze, Design, and Verify, focusing on meeting customer needs and achieving Six Sigma quality levels. Unlike DMAIC, which aims to improve existing processes, DMADV emphasizes innovation and creation, ensuring systematic development and validation before full-scale deployment. Key benefits of DMADV include risk reduction through thorough design verification and enhanced project success rates in complex product or service innovations.

Core Differences Between DMAIC and DMADV

DMAIC focuses on improving existing processes by defining, measuring, analyzing, improving, and controlling current operations, while DMADV targets the creation of new processes or products through define, measure, analyze, design, and verify phases. DMAIC is typically used for incremental improvements and problem-solving within established workflows, whereas DMADV drives innovation and design for Six Sigma projects aiming for defect-free performance. The core difference lies in DMAIC's process optimization role versus DMADV's emphasis on new product or process design and validation.

Applications of DMAIC in Industrial Engineering

DMAIC is predominantly applied in industrial engineering to enhance existing processes by defining problems, measuring key aspects, analyzing root causes, improving workflows, and controlling sustained performance. It is crucial for reducing defects, improving production efficiency, and optimizing quality control in manufacturing systems. Unlike DMADV, which targets new product or process development, DMAIC focuses on incremental improvements within established industrial operations.

When to Choose DMADV over DMAIC

DMADV is preferred over DMAIC when developing new processes or products where existing ones do not meet customer requirements, emphasizing design quality from the outset. It is suited for situations demanding radical innovation, new product development, or major process redesigns where incremental improvements are insufficient. Organizations should choose DMADV to ensure thorough validation, minimizing risks during initial implementation and achieving Six Sigma quality levels in new developments.

Key Tools Used in DMAIC vs DMADV

DMAIC primarily employs tools such as SIPOC diagrams, Cause and Effect analysis, Control Charts, and Pareto Charts to identify, analyze, improve, and control existing processes. DMADV utilizes tools like Quality Function Deployment (QFD), Failure Modes and Effects Analysis (FMEA), Design of Experiments (DOE), and process simulation to design new processes or products that meet customer specifications. Both methodologies leverage statistical data analysis but differ in their focus on improvement versus design.

Case Studies: DMAIC and DMADV in Practice

Case studies demonstrate that DMAIC excels in improving existing processes by identifying root causes and implementing targeted solutions, often resulting in measurable increases in efficiency and quality. DMADV is preferred in scenarios requiring new product or process designs, where innovative frameworks are applied to achieve Six Sigma quality standards from inception. Organizations such as General Electric and Motorola have successfully leveraged DMAIC for process optimization and DMADV for breakthrough product development, showcasing the strategic application of each Six Sigma methodology in practice.

Benefits and Limitations of Each Approach

DMAIC excels in improving existing processes by defining, measuring, analyzing, improving, and controlling performance, providing clear benefits for defect reduction and process optimization but limited in designing new processes. DMADV focuses on designing new processes or products using define, measure, analyze, design, and verify phases, offering advantages in innovation and quality assurance while being resource-intensive and time-consuming. Organizations must consider DMAIC's effectiveness for incremental improvement and DMADV's strength in new product or process development to balance efficiency and innovation.

Choosing the Right Method for Process Improvement

DMAIC is best suited for improving existing processes by identifying and eliminating defects through Define, Measure, Analyze, Improve, and Control phases, ensuring incremental improvements. DMADV focuses on designing new processes or products with Define, Measure, Analyze, Design, and Verify steps, optimizing for quality and customer requirements from the outset. Selecting between DMAIC and DMADV depends on whether the goal is to enhance an existing process or to develop a new solution aligned with Six Sigma principles.

Six Sigma Methodology

DMAIC improves existing Six Sigma processes by defining, measuring, analyzing, improving, and controlling, while DMADV designs new processes through defining, measuring, analyzing, designing, and verifying.

Continuous Improvement

DMAIC drives continuous improvement through measuring and refining existing processes, while DMADV focuses on designing new processes to meet excellence standards from the outset.

Process Optimization

DMAIC focuses on improving existing process performance by identifying and eliminating defects, while DMADV aims to design new processes or products with optimal quality and performance from the start.

Defect Reduction

DMAIC focuses on defect reduction by improving existing processes through Define, Measure, Analyze, Improve, and Control phases, while DMADV targets defect prevention by designing new processes or products with Define, Measure, Analyze, Design, and Verify steps.

Voice of the Customer (VoC)

DMAIC improves existing processes by analyzing Voice of the Customer (VoC) feedback to identify defects, while DMADV designs new processes with VoC as a foundational input to meet customer requirements from the outset.

Process Redesign

DMAIC optimizes existing processes through Define, Measure, Analyze, Improve, and Control, while DMADV drives process redesign by defining, measuring, analyzing, designing, and verifying new processes to meet customer specifications.

Design for Six Sigma (DFSS)

DMAIC improves existing processes through Define, Measure, Analyze, Improve, and Control phases, while DMADV designs new processes or products using Define, Measure, Analyze, Design, and Verify steps in Design for Six Sigma (DFSS) methodology.

Root Cause Analysis

DMAIC emphasizes root cause analysis to identify and eliminate defects in existing processes, while DMADV focuses on designing new processes or products without existing root cause issues.

Critical to Quality (CTQ)

DMAIC improves existing processes by identifying and measuring Critical to Quality (CTQ) factors for defect reduction, while DMADV designs new processes or products by defining and optimizing CTQ requirements to meet customer needs.

Statistical Process Control (SPC)

DMAIC emphasizes Statistical Process Control (SPC) for monitoring and improving existing processes, while DMADV integrates SPC primarily to design new processes with optimized quality control.

DMAIC vs DMADV Infographic

njnir.com

njnir.com