Kaizen emphasizes continuous, incremental improvements involving all employees to enhance efficiency and reduce waste in industrial engineering processes. Kaikaku, on the other hand, drives radical, large-scale changes that overhaul production systems for significant performance leaps. Both approaches aim to optimize operations but differ in scale and implementation speed.

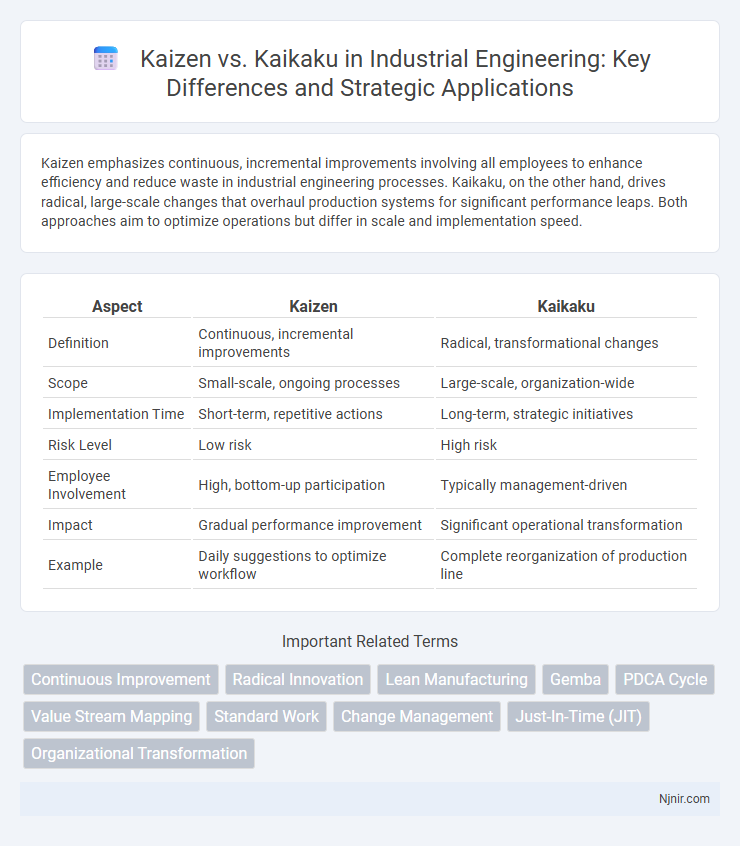

Table of Comparison

| Aspect | Kaizen | Kaikaku |

|---|---|---|

| Definition | Continuous, incremental improvements | Radical, transformational changes |

| Scope | Small-scale, ongoing processes | Large-scale, organization-wide |

| Implementation Time | Short-term, repetitive actions | Long-term, strategic initiatives |

| Risk Level | Low risk | High risk |

| Employee Involvement | High, bottom-up participation | Typically management-driven |

| Impact | Gradual performance improvement | Significant operational transformation |

| Example | Daily suggestions to optimize workflow | Complete reorganization of production line |

Introduction: Understanding Kaizen and Kaikaku

Kaizen emphasizes continuous, incremental improvements in processes to enhance efficiency and quality over time, promoting a culture of ongoing change. Kaikaku involves radical, transformative changes designed to overhaul existing systems rapidly for significant breakthroughs in performance. Both methodologies serve as strategic approaches in lean management, with Kaizen focusing on gradual enhancements while Kaikaku targets disruptive innovation.

Defining Kaizen: Continuous Improvement in Industry

Kaizen in industry refers to a continuous improvement philosophy that emphasizes small, incremental changes to enhance processes, efficiency, and quality consistently over time. Unlike kaikaku, which involves radical, breakthrough changes or complete system overhauls, kaizen focuses on daily improvements driven by employee involvement and data-driven problem-solving. This approach results in sustained operational excellence and waste reduction by fostering a culture of ongoing, incremental progress.

Defining Kaikaku: Radical Change for Transformation

Kaikaku represents radical change aimed at transforming business processes through large-scale innovation and restructuring, contrasting with Kaizen's focus on continuous, incremental improvements. This approach targets substantial shifts in organizational strategy, technology, or production methods to achieve dramatic performance enhancements. Companies adopting Kaikaku often implement breakthrough innovations that rapidly elevate efficiency, quality, or competitiveness across multiple departments.

Core Principles: Kaizen vs Kaikaku

Kaizen emphasizes continuous, incremental improvements driven by employee involvement and small, consistent changes, fostering a culture of ongoing efficiency and quality enhancement. Kaikaku involves radical, transformative change often initiated by leadership to overhaul processes or systems with significant impact in a short timeframe. Both approaches prioritize value creation and waste reduction but differ fundamentally in scale, speed, and implementation strategy.

Implementation Strategies in Industrial Settings

Kaizen emphasizes continuous, incremental improvements through employee-driven initiatives and routine process evaluations, fostering a culture of sustained operational excellence. Kaikaku involves radical, large-scale changes often initiated by management to quickly revolutionize production systems, focusing on breakthrough innovations and reengineering workflows. Implementing Kaizen requires consistent training and small team collaborations, whereas Kaikaku demands comprehensive planning, significant resource allocation, and top-down leadership commitment to transform industrial processes swiftly.

Impact on Productivity and Efficiency

Kaizen emphasizes continuous, incremental improvements that gradually enhance productivity and operational efficiency by reducing waste and optimizing existing processes. Kaikaku involves radical, transformative changes that fundamentally redesign workflows, often leading to significant leaps in efficiency and productivity by implementing breakthrough innovations. Organizations leveraging Kaizen benefit from sustained, steady growth, while those adopting Kaikaku experience rapid, substantial performance gains but face higher risks and resource demands.

Challenges and Barriers in Adopting Kaizen and Kaikaku

Implementing Kaizen faces challenges such as employee resistance to continuous incremental changes and a lack of sustained management commitment, which can hinder a culture of ongoing improvement. Kaikaku encounters barriers including higher costs, significant operational disruptions, and resistance to radical change from employees accustomed to existing workflows. Both approaches demand strong leadership, clear communication, and alignment of organizational goals to overcome obstacles and achieve successful transformation.

Case Studies: Success Stories in Industrial Engineering

Kaizen principles drove Toyota's continuous improvement, boosting productivity through incremental changes on assembly lines, while kaikaku was pivotal in Nissan's radical overhaul of its manufacturing process, reducing vehicle production time by 50%. Mitsubishi Heavy Industries utilized Kaizen for small, ongoing safety enhancements in their manufacturing plants, whereas a dramatic plant layout redesign based on kaikaku principles at Hitachi led to a 30% increase in overall equipment effectiveness (OEE). These case studies demonstrate how Kaizen fosters sustainable, long-term operational excellence and how Kaikaku enables breakthrough performance gains in industrial engineering.

Choosing the Right Approach: Factors to Consider

Choosing between Kaizen and Kaikaku depends on the organization's goals, scale of change, and time frame. Kaizen emphasizes continuous, incremental improvements that enhance processes gradually, making it suitable for long-term stability and employee involvement. Kaikaku entails radical, transformative changes that address systemic issues quickly, ideal for situations requiring rapid innovation or major restructuring.

Future Trends: The Evolution of Kaizen and Kaikaku in Industry

Future trends in industry highlight the increasing integration of Kaizen's continuous, incremental improvements with Kaikaku's radical, transformative changes to drive innovation and competitiveness. Advanced technologies such as AI, IoT, and data analytics are amplifying the impact of both methodologies by enabling real-time process optimization and large-scale process redesigns. The evolving industrial landscape emphasizes a hybrid approach, leveraging Kaizen's steady progress alongside Kaikaku's breakthrough innovations for sustainable growth.

Continuous Improvement

Kaizen emphasizes continuous incremental improvements fostering employee involvement, while Kaikaku involves radical, transformative changes implemented rapidly to overhaul processes.

Radical Innovation

Kaikaku drives radical innovation by implementing fundamental, transformative changes in processes, unlike Kaizen's gradual, incremental improvements.

Lean Manufacturing

Kaizen emphasizes continuous incremental improvements while Kaikaku involves radical, transformative changes in Lean Manufacturing to enhance efficiency and reduce waste.

Gemba

Kaizen promotes continuous incremental improvements at Gemba involving all employees, while Kaikaku implements radical transformational changes typically initiated by management to dramatically enhance processes on the shop floor.

PDCA Cycle

Kaizen emphasizes continuous PDCA cycle iterations for incremental improvements, whereas Kaikaku implements revolutionary changes by applying PDCA in large-scale process overhauls.

Value Stream Mapping

Value Stream Mapping enhances Kaizen by enabling continuous incremental improvements, while Kaikaku leverages it to identify radical changes for transformative process redesign.

Standard Work

Kaizen emphasizes continuous incremental improvements within Standard Work processes, while Kaikaku involves radical changes that often redefine Standard Work entirely.

Change Management

Kaizen emphasizes continuous incremental change for sustainable improvement, while Kaikaku involves radical, transformational change for rapid organizational restructuring in change management.

Just-In-Time (JIT)

Kaizen enhances Just-In-Time (JIT) production through continuous incremental improvements, while Kaikaku implements radical, large-scale changes to overhaul JIT systems for immediate performance gains.

Organizational Transformation

Kaikaku drives radical organizational transformation through rapid, large-scale changes, while Kaizen facilitates continuous incremental improvements that gradually optimize processes within the organization.

kaizen vs kaikaku Infographic

njnir.com

njnir.com