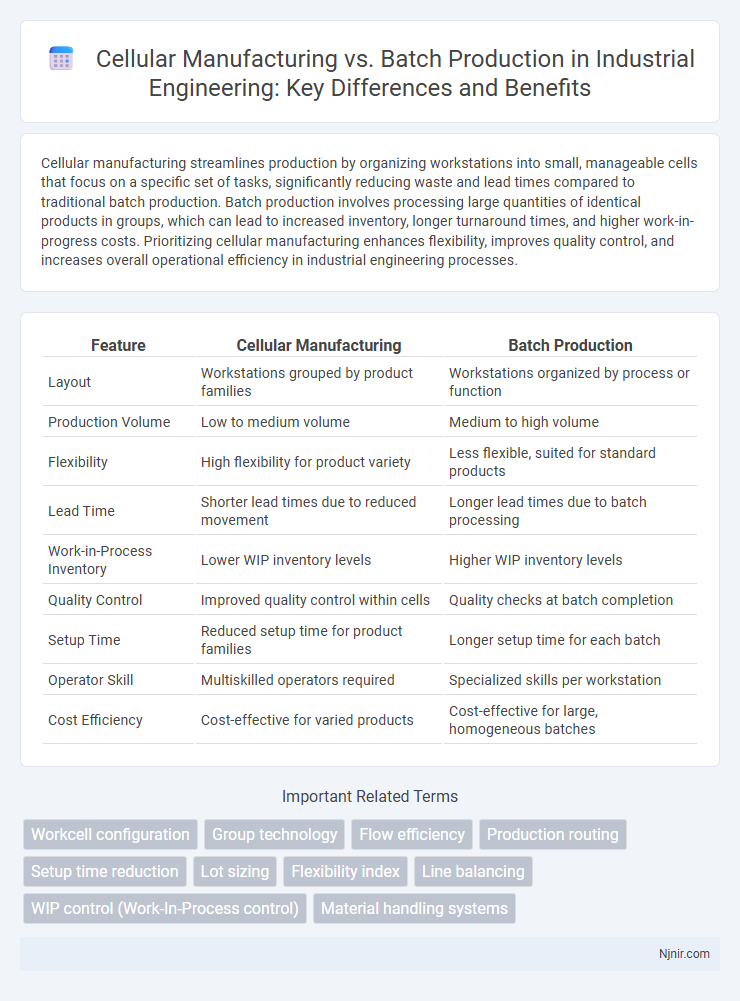

Cellular manufacturing streamlines production by organizing workstations into small, manageable cells that focus on a specific set of tasks, significantly reducing waste and lead times compared to traditional batch production. Batch production involves processing large quantities of identical products in groups, which can lead to increased inventory, longer turnaround times, and higher work-in-progress costs. Prioritizing cellular manufacturing enhances flexibility, improves quality control, and increases overall operational efficiency in industrial engineering processes.

Table of Comparison

| Feature | Cellular Manufacturing | Batch Production |

|---|---|---|

| Layout | Workstations grouped by product families | Workstations organized by process or function |

| Production Volume | Low to medium volume | Medium to high volume |

| Flexibility | High flexibility for product variety | Less flexible, suited for standard products |

| Lead Time | Shorter lead times due to reduced movement | Longer lead times due to batch processing |

| Work-in-Process Inventory | Lower WIP inventory levels | Higher WIP inventory levels |

| Quality Control | Improved quality control within cells | Quality checks at batch completion |

| Setup Time | Reduced setup time for product families | Longer setup time for each batch |

| Operator Skill | Multiskilled operators required | Specialized skills per workstation |

| Cost Efficiency | Cost-effective for varied products | Cost-effective for large, homogeneous batches |

Introduction to Cellular Manufacturing and Batch Production

Cellular manufacturing organizes workstations into small, self-contained units called cells, each dedicated to producing a specific product or component, enhancing workflow efficiency and reducing lead times. Batch production involves producing goods in defined groups or quantities, allowing flexibility for varying customer demands but often leading to longer setup times and potential inventory buildup. Both methods address different production needs: cellular manufacturing emphasizes streamlined processes and quality control, while batch production offers adaptability for diverse product lines.

Core Principles: Cellular Manufacturing Explained

Cellular manufacturing organizes workstations into cells, each dedicated to producing a specific product family, minimizing movement and enhancing workflow efficiency. This method emphasizes continuous flow, reduction of waste, and cross-trained workers who handle multiple tasks within the cell. Compared to batch production, which processes large lots in sequential stages, cellular manufacturing promotes flexibility, faster production cycles, and improved quality control through focused teamwork.

Core Principles: Understanding Batch Production

Batch production involves manufacturing a set quantity of identical products in groups or batches, allowing for flexibility and customization while maintaining cost efficiency. Core principles include job sequencing, batch size determination, and efficient setup times to minimize production delays and inventory buildup. This method contrasts with cellular manufacturing, which organizes workstations into cells to produce families of parts continuously, emphasizing flow and reduced lead times.

Workflow and Process Layout Differences

Cellular manufacturing organizes workstations into a U-shaped layout, enabling continuous flow and minimizing material handling between process steps. Batch production uses separate functional departments arranged by process type, leading to longer wait times and increased work-in-progress inventory. This difference in process layout impacts overall workflow efficiency, with cellular manufacturing promoting faster cycle times and smoother transitions.

Efficiency and Productivity Comparison

Cellular manufacturing streamlines workflow by grouping machines into cells dedicated to producing similar products, significantly reducing setup times and material handling, which enhances overall efficiency. In contrast, batch production often experiences longer downtimes and increased work-in-progress inventory due to its segmented processing approach, limiting productivity. Studies reveal cellular manufacturing can boost production rates by up to 30% while reducing lead times by 40%, highlighting its superiority in optimizing factory floor performance compared to traditional batch methods.

Flexibility and Adaptability of Each System

Cellular manufacturing enhances flexibility by organizing workstations into small, self-contained cells that enable rapid adjustments to product variations and volume changes. Batch production offers less adaptability, as it relies on large batches and fixed setups that require more time and effort to switch between different products. The cellular approach supports quicker turnaround and customization, making it ideal for dynamic markets with fluctuating demands.

Quality Control in Cellular vs Batch Production

Cellular manufacturing enhances quality control by organizing workstations in close proximity, facilitating real-time inspection and quicker defect detection compared to batch production, where quality checks often occur post-process, delaying feedback. Continuous flow in cellular systems minimizes variability and reduces error rates, improving consistency and product standards. Batch production's segmented approach increases the risk of cumulative defects, making defect isolation and root cause analysis more complex.

Cost Implications and Resource Utilization

Cellular manufacturing reduces costs by minimizing work-in-progress inventory and streamlining material flow, leading to lower handling and storage expenses compared to batch production. It maximizes resource utilization through dedicated, multifunctional work cells that enhance labor efficiency and reduce setup times, whereas batch production often incurs higher costs due to frequent machine setups and idle times. This approach results in faster throughput and lower overhead costs, making cellular systems more cost-effective in high-mix, low-volume environments.

Technological Integration and Automation

Cellular manufacturing leverages advanced automation technologies and integrated robotics to streamline workflows within dedicated work cells, enhancing efficiency and reducing manual intervention. Batch production, while increasingly adopting automation, often relies on less flexible systems that accommodate varied product types but struggle with seamless technological integration. The heightened precision and real-time data analytics in cellular manufacturing enable superior process control and faster adaptation to production changes compared to traditional batch processes.

Choosing the Right System for Your Manufacturing Needs

Cellular manufacturing enhances workflow efficiency by organizing workstations into cells that focus on specific product families, reducing setup time and inventory levels compared to batch production, which processes large quantities in separate stages. Selecting the right system depends on product complexity, production volume, and flexibility requirements, with cellular manufacturing excelling in custom, high-mix environments and batch production suited for standardized, large-scale runs. Evaluating factors such as lead time, production cost, and quality control will guide manufacturers in optimizing their operations for improved productivity and responsiveness.

Workcell configuration

Cellular manufacturing arranges workcells to enable continuous flow and minimize movement, enhancing efficiency compared to the segmented station layout found in batch production.

Group technology

Cellular manufacturing leverages Group Technology to organize similar parts into cells, significantly reducing setup time and improving workflow efficiency compared to traditional batch production.

Flow efficiency

Cellular manufacturing enhances flow efficiency by minimizing work-in-progress and reducing wait times through streamlined, sequential processes, whereas batch production often suffers from lower flow efficiency due to larger batch sizes and increased inventory buildup between stages.

Production routing

Cellular manufacturing optimizes production routing by grouping machines into cells for streamlined, continuous flow, whereas batch production relies on separate, sequential routing that often involves longer material handling and wait times.

Setup time reduction

Cellular manufacturing reduces setup time by organizing workstations in a U-shaped cell for continuous flow, unlike batch production which requires longer setup times due to equipment changes between batches.

Lot sizing

Cellular manufacturing optimizes small lot sizing by grouping machines for continuous flow, whereas batch production relies on larger lot sizes that increase inventory and lead times.

Flexibility index

Cellular manufacturing typically achieves a higher flexibility index than batch production by enabling faster changeovers and more adaptable workflows.

Line balancing

Cellular manufacturing enhances line balancing by grouping similar processes into cells, reducing bottlenecks and idle time compared to the uneven workflow typical in batch production.

WIP control (Work-In-Process control)

Cellular manufacturing significantly reduces Work-In-Process (WIP) inventory by streamlining production flow within dedicated cells, whereas batch production typically leads to higher WIP levels due to sequential processing and batch queuing.

Material handling systems

Cellular manufacturing minimizes material handling by grouping machines in a flow sequence, reducing transit time and damage compared to batch production's repetitive movement between distant workstations.

cellular manufacturing vs batch production Infographic

njnir.com

njnir.com