Process simulation enables detailed analysis and optimization of manufacturing workflows through digital models, reducing time and costs associated with physical trials. Physical prototyping provides tangible validation of product designs and process feasibility but often involves higher expenses and longer development cycles. Integrating both approaches can enhance decision-making accuracy and streamline industrial engineering projects.

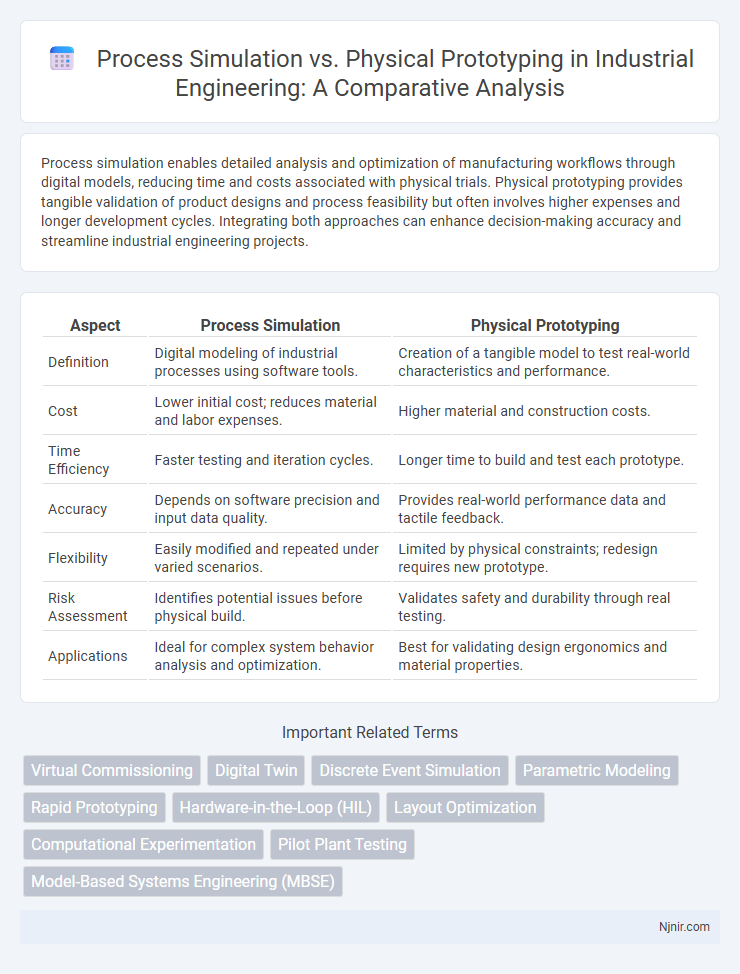

Table of Comparison

| Aspect | Process Simulation | Physical Prototyping |

|---|---|---|

| Definition | Digital modeling of industrial processes using software tools. | Creation of a tangible model to test real-world characteristics and performance. |

| Cost | Lower initial cost; reduces material and labor expenses. | Higher material and construction costs. |

| Time Efficiency | Faster testing and iteration cycles. | Longer time to build and test each prototype. |

| Accuracy | Depends on software precision and input data quality. | Provides real-world performance data and tactile feedback. |

| Flexibility | Easily modified and repeated under varied scenarios. | Limited by physical constraints; redesign requires new prototype. |

| Risk Assessment | Identifies potential issues before physical build. | Validates safety and durability through real testing. |

| Applications | Ideal for complex system behavior analysis and optimization. | Best for validating design ergonomics and material properties. |

Introduction to Process Simulation and Physical Prototyping

Process simulation uses advanced software tools to create virtual models that replicate manufacturing or operational processes, enabling analysis and optimization without the need for physical materials. Physical prototyping involves constructing tangible models or components to directly test and evaluate design performance under real-world conditions. Combining both methods accelerates product development by identifying potential issues early while validating design feasibility through hands-on experimentation.

Defining Process Simulation in Industrial Engineering

Process simulation in industrial engineering involves using advanced software tools to create digital models of manufacturing or production processes, enabling detailed analysis and optimization without physical trials. This approach allows engineers to predict process performance, identify bottlenecks, and test various scenarios to improve efficiency and reduce costs. Compared to physical prototyping, process simulation significantly accelerates development cycles while minimizing resource consumption and operational risks.

Overview of Physical Prototyping Methods

Physical prototyping methods include additive manufacturing, CNC machining, and casting, enabling tangible evaluation of design concepts. These techniques provide direct insights into material properties, functionality, and ergonomics, critical for validating engineering specifications. Despite higher costs and longer development times compared to process simulation, physical prototypes remain essential for detecting unforeseen issues and achieving precise real-world performance assessments.

Comparative Analysis: Simulation vs Prototyping

Process simulation offers rapid, cost-effective testing of design variations through digital models, enabling precise prediction of system behavior under diverse conditions. In contrast, physical prototyping provides tangible validation and real-world performance insights but involves higher material and labor expenses, along with longer development cycles. Combining both approaches enhances accuracy, reduces risk, and optimizes product development efficiency by leveraging virtual analysis with hands-on experimentation.

Cost Efficiency: Simulation versus Physical Models

Process simulation significantly reduces costs by eliminating the need for expensive materials and labor associated with physical prototyping. Virtual models enable rapid iterations and early detection of design flaws, minimizing the financial risk of costly physical errors. Physical prototyping requires more resources for setup, manufacturing, and testing, making simulation a more cost-efficient approach for product development.

Time-to-Market Considerations

Process simulation significantly reduces time-to-market by enabling rapid virtual testing and iteration of designs without the delays associated with building physical prototypes. Physical prototyping, while valuable for hands-on validation, often involves longer lead times due to manufacturing, assembly, and rework cycles. Leveraging advanced simulation software accelerates product development timelines, allowing faster decision-making and market entry.

Accuracy and Predictive Capabilities

Process simulation offers higher accuracy in predicting system behavior by utilizing detailed mathematical models and real-time data integration, enabling precise forecasting of outcomes before physical implementation. Physical prototyping provides tangible validation but often involves higher costs and longer development cycles, with limitations in replicating complex operating conditions. The predictive capabilities of process simulation surpass physical prototyping by allowing virtual testing of multiple scenarios, reducing uncertainties and optimizing designs efficiently.

Scalability and Flexibility in Manufacturing

Process simulation offers unparalleled scalability and flexibility in manufacturing by enabling rapid adjustments to production variables without the costs and time associated with physical prototyping. Digital twins and virtual modeling allow manufacturers to test multiple scenarios, optimize processes, and scale operations efficiently while minimizing risks. Physical prototyping, while valuable for tangible validation, often lacks the adaptability and speed required for iterative scaling and flexibility in modern manufacturing environments.

Integration with Digital Manufacturing Systems

Process simulation offers seamless integration with digital manufacturing systems by enabling real-time data exchange, predictive analytics, and virtual testing of production workflows. Physical prototyping, while valuable for tactile validation, often lacks direct connectivity to digital platforms, limiting its effectiveness in dynamic process adjustments and automated feedback loops. Incorporating process simulation enhances decision-making efficiency, reduces time-to-market, and supports continuous optimization in Industry 4.0 environments.

Future Trends in Process Simulation and Prototyping

Future trends in process simulation emphasize the integration of artificial intelligence and machine learning to enhance accuracy and reduce development time by predicting outcomes and optimizing parameters in real-time. Advanced digital twins and augmented reality are transforming physical prototyping by enabling immersive, interactive testing environments that minimize material waste and production costs. The convergence of cloud computing and IoT technologies facilitates collaborative, scalable simulation platforms that accelerate innovation cycles across manufacturing and product design industries.

Virtual Commissioning

Virtual commissioning accelerates system validation by using process simulation to replicate physical prototyping environments, reducing time and costs in manufacturing automation.

Digital Twin

Digital twin technology enhances process simulation by creating real-time, data-driven virtual replicas of physical prototypes, enabling dynamic testing and optimization without costly or time-consuming physical iterations.

Discrete Event Simulation

Discrete Event Simulation offers cost-effective, detailed process analysis and optimization by modeling workflows virtually, reducing the need for expensive and time-consuming physical prototyping.

Parametric Modeling

Parametric modeling in process simulation enables rapid design iterations and accurate performance predictions that reduce the time and cost compared to traditional physical prototyping.

Rapid Prototyping

Rapid prototyping leverages process simulation to accelerate design validation by virtually testing product performance, reducing the time and cost compared to traditional physical prototyping.

Hardware-in-the-Loop (HIL)

Hardware-in-the-Loop (HIL) enhances process simulation by integrating real hardware components for real-time testing, reducing costs and development time compared to traditional physical prototyping.

Layout Optimization

Process simulation enables precise layout optimization by modeling workflows and resource allocation digitally, reducing costs and time compared to physical prototyping.

Computational Experimentation

Computational experimentation in process simulation enables precise virtual testing and optimization of manufacturing workflows, significantly reducing time and costs compared to traditional physical prototyping.

Pilot Plant Testing

Pilot plant testing bridges process simulation and physical prototyping by providing scalable, real-world data to validate models and optimize production before full-scale manufacturing.

Model-Based Systems Engineering (MBSE)

Model-Based Systems Engineering (MBSE) enhances process simulation by enabling accurate virtual prototyping and system validation, reducing the cost and time compared to traditional physical prototyping.

Process Simulation vs Physical Prototyping Infographic

njnir.com

njnir.com