Value stream mapping provides a comprehensive overview of material and information flow across the entire production system, identifying value-added and non-value-added activities to optimize overall efficiency. Process mapping, on the other hand, focuses on detailing individual process steps within a specific segment to improve task-level accuracy and control. Combining both approaches enables industrial engineers to enhance throughput and reduce waste systematically.

Table of Comparison

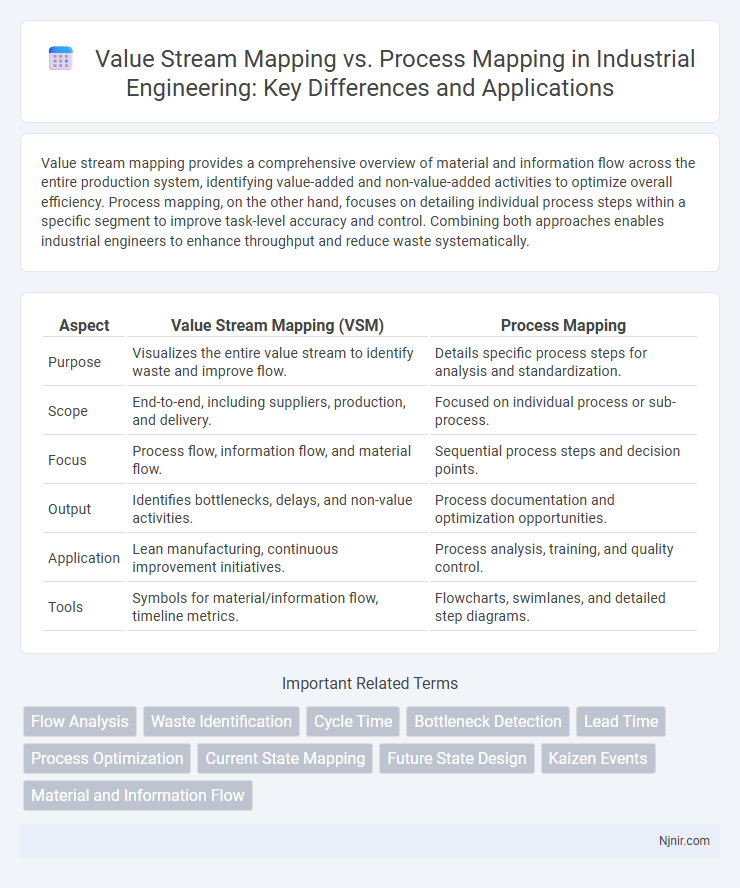

| Aspect | Value Stream Mapping (VSM) | Process Mapping |

|---|---|---|

| Purpose | Visualizes the entire value stream to identify waste and improve flow. | Details specific process steps for analysis and standardization. |

| Scope | End-to-end, including suppliers, production, and delivery. | Focused on individual process or sub-process. |

| Focus | Process flow, information flow, and material flow. | Sequential process steps and decision points. |

| Output | Identifies bottlenecks, delays, and non-value activities. | Process documentation and optimization opportunities. |

| Application | Lean manufacturing, continuous improvement initiatives. | Process analysis, training, and quality control. |

| Tools | Symbols for material/information flow, timeline metrics. | Flowcharts, swimlanes, and detailed step diagrams. |

Introduction to Value Stream Mapping and Process Mapping

Value Stream Mapping (VSM) focuses on visualizing the flow of materials and information required to deliver a product or service, highlighting value-adding and non-value-adding activities to identify waste and improve overall efficiency. Process Mapping, on the other hand, details each step within a specific process, emphasizing the sequence of tasks and decision points to analyze performance and pinpoint bottlenecks. Both techniques serve as powerful tools in Lean management, with VSM providing a broader value chain perspective while Process Mapping offers granular insights into individual workflows.

Core Principles of Value Stream Mapping

Value Stream Mapping (VSM) emphasizes identifying and eliminating waste within the entire value stream to enhance flow and reduce lead time, focusing on both material and information flow from supplier to customer. Core principles include mapping the current state to visualize inefficiencies, designing a future state to create a leaner process, and implementing continuous improvement cycles to sustain gains. Unlike traditional process mapping, which details individual process steps, VSM provides a holistic overview that aligns operations with customer value creation and operational excellence.

Fundamental Concepts of Process Mapping

Value stream mapping visualizes the flow of materials and information through all steps of a production process, identifying value-added and non-value-added activities. Process mapping, in contrast, outlines individual tasks and decision points within a specific process, emphasizing task sequences and responsible parties. Fundamental concepts of process mapping include defining process boundaries, documenting each activity in chronological order, and identifying inputs, outputs, and decision nodes to enhance workflow clarity and efficiency.

Key Differences Between Value Stream Mapping and Process Mapping

Value stream mapping emphasizes the flow of materials and information to identify waste and optimize the entire production process, while process mapping focuses on detailing individual tasks or steps within a specific process. Key differences include value stream mapping's broader scope that captures customer value and lead times, compared to process mapping's detailed view for analyzing task sequences and decision points. Value stream mapping integrates metrics like cycle time, takt time, and inventory levels, enabling strategic improvements, whereas process mapping is primarily used for documenting and standardizing workflow steps.

Applications of Value Stream Mapping in Industrial Engineering

Value Stream Mapping (VSM) in industrial engineering is primarily applied to identify and eliminate waste across manufacturing and production processes, enhancing overall efficiency and product flow. It provides a comprehensive visualization of material and information flow, enabling engineers to pinpoint bottlenecks and non-value-added activities that traditional process mapping might overlook. VSM supports lean manufacturing initiatives by highlighting opportunities for continuous improvement and facilitating strategic decision-making to optimize resource allocation and reduce lead times.

Process Mapping Use Cases in Manufacturing Operations

Process mapping in manufacturing operations helps visualize workflows, identify bottlenecks, and improve efficiency by detailing each step of production. It supports quality control, resource allocation, and training by providing a clear representation of tasks and decision points. Process mapping is essential for continuous improvement initiatives, reducing waste, and standardizing procedures across manufacturing plants.

Benefits and Limitations of Value Stream Mapping

Value Stream Mapping (VSM) offers a detailed visualization of material and information flow across the entire production process, highlighting waste and opportunities for improvement that traditional process mapping may overlook. It enables identification of both value-adding and non-value-adding activities, facilitating Lean manufacturing and operational efficiency enhancements. However, VSM can be time-consuming to create and maintain, often requiring cross-functional collaboration and extensive data collection, which may limit its practicality for smaller or less complex processes.

Advantages and Drawbacks of Process Mapping

Process mapping offers distinct advantages such as providing a clear, step-by-step visualization of workflows, which enhances communication and identifies inefficiencies in specific tasks. It allows organizations to standardize procedures and improve consistency across departments, contributing to better quality control and training. However, process mapping can be time-consuming and may oversimplify complex processes, potentially overlooking broader system interactions that value stream mapping captures more effectively.

Choosing the Appropriate Mapping Method for Your Organization

Value stream mapping provides a comprehensive overview of the entire production flow, highlighting waste and inefficiencies, while process mapping zooms in on individual tasks or subprocesses for detailed analysis. Organizations aiming to improve overall operational efficiency benefit from value stream mapping's holistic perspective, whereas those focusing on specific departmental workflows may find process mapping more effective. Selecting the appropriate method depends on the scope of improvement desired, the complexity of processes, and targeted outcomes for process optimization.

Integrating Value Stream Mapping and Process Mapping for Continuous Improvement

Integrating Value Stream Mapping (VSM) with process mapping enhances continuous improvement by combining VSM's focus on identifying waste and flow inefficiencies with process mapping's detailed visualization of individual steps and decision points. This integration enables organizations to pinpoint value-adding activities and bottlenecks more accurately, facilitating targeted process optimization and improved cycle times. Leveraging tools such as SIPOC diagrams alongside VSM fosters a comprehensive understanding of both macro and micro-level process dynamics, driving sustained operational excellence.

Flow Analysis

Value stream mapping emphasizes identifying value-added and non-value-added steps to optimize flow and eliminate waste, while process mapping provides a detailed step-by-step visualization without inherently focusing on flow efficiency.

Waste Identification

Value stream mapping identifies waste by visualizing material and information flow across the entire production system, while process mapping focuses on detailed task-level activities, making value stream mapping more effective for holistic waste identification.

Cycle Time

Value Stream Mapping provides a comprehensive visualization of cycle time across the entire production flow, while Process Mapping focuses on cycle time within individual process steps.

Bottleneck Detection

Value stream mapping identifies bottlenecks by analyzing the flow of materials and information across the entire value chain, whereas process mapping detects bottlenecks by detailing individual process steps and their cycle times.

Lead Time

Value stream mapping highlights lead time by visualizing the entire flow of value-added and non-value-added activities, whereas process mapping typically focuses on individual process steps without emphasizing overall lead time.

Process Optimization

Value stream mapping identifies waste and flow inefficiencies across the entire value chain to optimize end-to-end process performance, while process mapping focuses on detailing individual steps within a process for localized optimization and clarity.

Current State Mapping

Current State Mapping in value stream mapping visually identifies all value-adding and non-value-adding activities across the entire production flow, while process mapping typically focuses on detailed steps within individual functions.

Future State Design

Value stream mapping emphasizes identifying and eliminating waste to design an optimized Future State, while process mapping focuses on detailing each step for clarity without inherently targeting future improvements.

Kaizen Events

Value stream mapping identifies waste and improvement opportunities across entire production flows during Kaizen Events, whereas process mapping details specific process steps to analyze bottlenecks and enhance efficiency within those events.

Material and Information Flow

Value stream mapping visualizes both material and information flow across the entire production process to identify waste, while process mapping focuses primarily on detailing individual task sequences without emphasizing flow dynamics.

value stream mapping vs process mapping Infographic

njnir.com

njnir.com