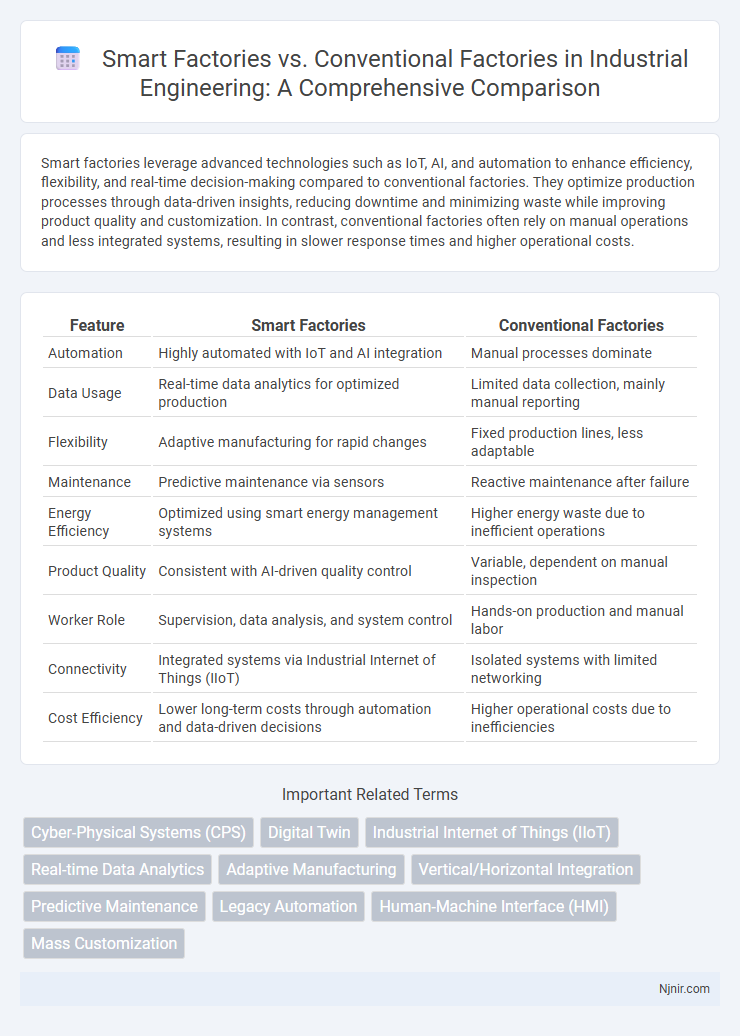

Smart factories leverage advanced technologies such as IoT, AI, and automation to enhance efficiency, flexibility, and real-time decision-making compared to conventional factories. They optimize production processes through data-driven insights, reducing downtime and minimizing waste while improving product quality and customization. In contrast, conventional factories often rely on manual operations and less integrated systems, resulting in slower response times and higher operational costs.

Table of Comparison

| Feature | Smart Factories | Conventional Factories |

|---|---|---|

| Automation | Highly automated with IoT and AI integration | Manual processes dominate |

| Data Usage | Real-time data analytics for optimized production | Limited data collection, mainly manual reporting |

| Flexibility | Adaptive manufacturing for rapid changes | Fixed production lines, less adaptable |

| Maintenance | Predictive maintenance via sensors | Reactive maintenance after failure |

| Energy Efficiency | Optimized using smart energy management systems | Higher energy waste due to inefficient operations |

| Product Quality | Consistent with AI-driven quality control | Variable, dependent on manual inspection |

| Worker Role | Supervision, data analysis, and system control | Hands-on production and manual labor |

| Connectivity | Integrated systems via Industrial Internet of Things (IIoT) | Isolated systems with limited networking |

| Cost Efficiency | Lower long-term costs through automation and data-driven decisions | Higher operational costs due to inefficiencies |

Introduction to Smart and Conventional Factories

Smart factories integrate advanced technologies such as IoT, AI, and robotics to enable real-time data exchange and automated processes, enhancing efficiency and flexibility. Conventional factories rely primarily on manual labor and traditional machinery, with limited automation and slower response to production changes. The shift to smart factories transforms manufacturing through interconnected systems that optimize operations, reduce downtime, and improve product quality.

Core Principles of Smart Factories

Smart factories leverage advanced technologies such as IoT, AI, and robotics to enable real-time data exchange, automation, and predictive maintenance, leading to increased efficiency and flexibility. Core principles include connectivity, where machines and systems communicate seamlessly, and data-driven decision-making powered by continuous analytics. These factories emphasize adaptability through modular production systems, allowing rapid customization and minimal downtime compared to conventional factories reliant on manual processes and fixed workflows.

Key Characteristics of Conventional Factories

Conventional factories primarily rely on manual processes and human labor, with limited automation and minimal integration of digital technologies. Production is often linear and rigid, featuring separate workflows that hinder real-time data sharing and adaptive decision-making. Equipment maintenance and quality control are typically reactive, leading to longer downtimes and inconsistent product quality compared to smart factory environments.

Technology Integration in Manufacturing Processes

Smart factories leverage advanced technologies such as IoT sensors, AI-driven analytics, and automation systems to seamlessly integrate manufacturing processes, enhancing real-time data exchange and operational efficiency. Conventional factories rely heavily on manual controls and isolated machinery, resulting in slower response times and limited process visibility. The integration of digital technologies in smart factories enables predictive maintenance, adaptive production workflows, and improved quality control compared to traditional manufacturing setups.

Operational Efficiency: Smart vs Conventional

Smart factories leverage IoT sensors, real-time data analytics, and automation to optimize production workflows, drastically reducing downtime and waste compared to conventional factories. Machine learning algorithms enable predictive maintenance, enhancing equipment lifespan and operational efficiency beyond the reactive approach typical of traditional manufacturing. Conventional factories rely heavily on manual monitoring, resulting in slower response times and higher operational costs due to unplanned stoppages and less precise resource allocation.

Workforce and Skill Requirements

Smart factories require a workforce skilled in digital technologies, robotics, and data analytics, emphasizing continuous learning and adaptability to operate advanced automated systems. Conventional factories depend more on manual labor and routine skills, with less emphasis on digital proficiency and technological integration. The transition to smart manufacturing drives demand for multidisciplinary expertise and fosters upskilling to maintain competitiveness in Industry 4.0 environments.

Data Utilization and Decision-Making

Smart factories leverage advanced data analytics and real-time sensor data to optimize production processes and enable predictive maintenance, significantly improving operational efficiency. Conventional factories rely primarily on manual data collection and historical records, which often results in slower decision-making and less accuracy. The integration of IoT and AI in smart factories facilitates dynamic decision-making through continuous data feedback, whereas conventional factories depend on static data inputs, limiting agility and responsiveness.

Sustainability and Environmental Impact

Smart factories utilize advanced IoT technologies and real-time data analytics to optimize energy consumption, significantly reducing carbon footprints compared to conventional factories that rely on less efficient, manual processes. Automation in smart factories minimizes waste through precision manufacturing and predictive maintenance, whereas traditional factories often generate higher levels of scrap and emissions. Environmental sustainability in smart factories is further enhanced by integrating renewable energy sources and closed-loop recycling systems, outperforming conventional factory models in reducing environmental impact.

Cost Implications and Return on Investment

Smart factories leverage automation, IoT, and AI technologies to optimize production processes, significantly reducing labor costs and minimizing downtime, which lowers overall operational expenses compared to conventional factories. Initial capital investment for smart factories is higher due to advanced equipment and software integration, but the improved efficiency and predictive maintenance capabilities lead to faster Return on Investment (ROI) through enhanced productivity and reduced waste. In contrast, conventional factories face ongoing high labor and maintenance costs, resulting in slower ROI despite lower upfront expenditures.

Future Prospects and Industrial Evolution

Smart factories leverage IoT, AI, and robotics to enable real-time data analytics, predictive maintenance, and adaptive manufacturing processes, driving unprecedented efficiency and customization. Future prospects involve seamless integration of digital twins, advanced machine learning algorithms, and decentralized supply chains, fostering resilient and scalable industrial ecosystems. The industrial evolution is marked by a shift from manual labor and rigid production lines in conventional factories to autonomous, interconnected systems in smart factories, accelerating Industry 4.0 transformation and sustainable manufacturing practices.

Cyber-Physical Systems (CPS)

Smart factories leverage advanced Cyber-Physical Systems (CPS) integrating IoT sensors, real-time data analytics, and autonomous robotics to optimize production efficiency and flexibility, unlike conventional factories that rely on manual processes and isolated machinery.

Digital Twin

Digital Twin technology enables smart factories to simulate and optimize production processes in real-time, significantly enhancing efficiency and predictive maintenance compared to conventional factories.

Industrial Internet of Things (IIoT)

Smart factories leverage Industrial Internet of Things (IIoT) technologies to enhance real-time data analytics, automation, and predictive maintenance, significantly outperforming conventional factories in efficiency and operational agility.

Real-time Data Analytics

Smart factories leverage real-time data analytics to optimize production efficiency, reduce downtime, and enable predictive maintenance, outperforming conventional factories that rely on delayed and manual data processing.

Adaptive Manufacturing

Smart factories leverage adaptive manufacturing technologies such as IoT, AI, and real-time data analytics to optimize production processes and enable dynamic responsiveness, whereas conventional factories rely on fixed, manual operations with limited flexibility.

Vertical/Horizontal Integration

Smart factories achieve superior operational efficiency and real-time data flow through seamless vertical and horizontal integration, unlike conventional factories that rely on isolated, fragmented processes.

Predictive Maintenance

Smart factories utilize advanced IoT sensors and AI algorithms for predictive maintenance, significantly reducing downtime and maintenance costs compared to conventional factories that rely on reactive or scheduled maintenance methods.

Legacy Automation

Smart factories integrate advanced IoT and AI technologies to overcome legacy automation limitations in conventional factories, enhancing real-time data analysis, flexibility, and operational efficiency.

Human-Machine Interface (HMI)

Smart factories leverage advanced Human-Machine Interface (HMI) technologies like touchscreens, voice recognition, and augmented reality to enhance real-time monitoring and control, whereas conventional factories rely on basic, manual interfaces that limit operational efficiency and data integration.

Mass Customization

Smart factories leverage advanced automation and IoT technologies to enable efficient mass customization, unlike conventional factories that rely on standardized mass production with limited flexibility.

Smart factories vs Conventional factories Infographic

njnir.com

njnir.com