Push systems in industrial engineering rely on forecast-driven production schedules, aiming to optimize efficiency by anticipating demand. Pull systems, conversely, initiate production based on actual customer demand, minimizing inventory and reducing waste. Implementing a pull system enhances responsiveness and aligns production closely with real-time consumption patterns.

Table of Comparison

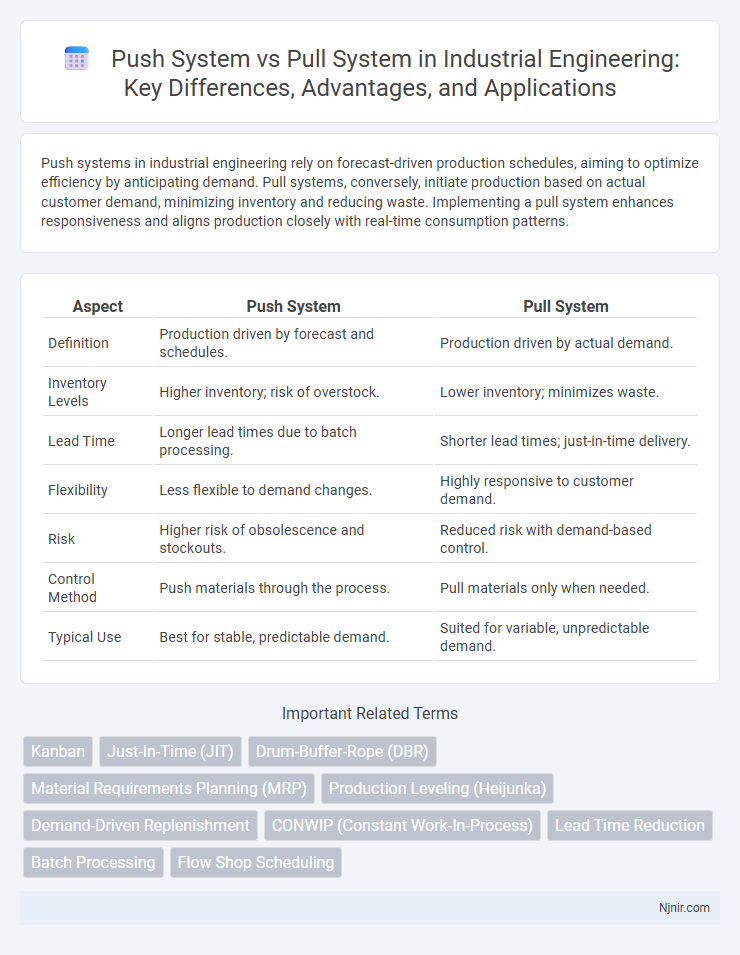

| Aspect | Push System | Pull System |

|---|---|---|

| Definition | Production driven by forecast and schedules. | Production driven by actual demand. |

| Inventory Levels | Higher inventory; risk of overstock. | Lower inventory; minimizes waste. |

| Lead Time | Longer lead times due to batch processing. | Shorter lead times; just-in-time delivery. |

| Flexibility | Less flexible to demand changes. | Highly responsive to customer demand. |

| Risk | Higher risk of obsolescence and stockouts. | Reduced risk with demand-based control. |

| Control Method | Push materials through the process. | Pull materials only when needed. |

| Typical Use | Best for stable, predictable demand. | Suited for variable, unpredictable demand. |

Introduction to Push and Pull Systems in Industrial Engineering

Push systems in industrial engineering rely on forecasted demand to schedule production and inventory replenishment, often leading to excess inventory and slower response to market changes. Pull systems operate based on actual customer demand, triggering production only when needed, which minimizes waste and enhances flexibility. Implementing pull systems, such as Just-In-Time (JIT), improves efficiency by aligning production closely with consumption patterns, reducing lead times and inventory holding costs.

Fundamental Principles of Push Systems

Push systems operate based on forecasted demand, where production and inventory decisions are made in advance and goods are pushed through the supply chain. These systems rely on predetermined schedules, aiming to optimize manufacturing efficiency by maintaining consistent workflow and minimizing downtime. Inventory levels in push systems are typically higher due to the anticipation of customer demand rather than real-time order signals.

Core Concepts of Pull Systems

Pull systems operate on the core principle of producing goods based on actual customer demand, minimizing inventory levels and reducing waste. This approach relies on real-time demand signals to trigger production, ensuring resources are utilized only when needed. Key elements include just-in-time delivery, continuous flow, and the use of kanban cards to control workflow and prevent overproduction.

Comparison: Push System vs Pull System

Push systems forecast demand and produce goods in advance, leading to high inventory levels and potential overproduction, whereas pull systems rely on actual customer demand to initiate production, minimizing inventory and reducing waste. Push systems suit environments with predictable demand and long production lead times, while pull systems excel in flexible, just-in-time manufacturing settings requiring rapid response to market changes. Efficiency metrics often show pull systems achieving lower inventory costs and higher responsiveness, contrasting with push systems' ability to optimize for economies of scale.

Inventory Management in Push and Pull Systems

Inventory management in push systems relies on forecast-driven production, resulting in higher stock levels and increased risk of excess or obsolete inventory. Pull systems manage inventory based on actual customer demand, which minimizes stock levels and reduces carrying costs by producing only what is needed. Efficient pull inventory practices enhance responsiveness and decrease waste, while push systems may suffer from rigidity and increased inventory holding costs.

Impact on Production Efficiency

Push systems schedule production based on forecasted demand, often leading to overproduction and increased inventory costs that reduce overall efficiency. Pull systems rely on actual customer demand to trigger production, minimizing waste and aligning output closely with consumption, thereby enhancing efficiency. Implementing pull systems can streamline workflows, reduce lead times, and improve resource utilization within manufacturing processes.

Flexibility and Responsiveness to Demand

Pull systems enhance flexibility and responsiveness by producing goods based on actual customer demand, minimizing overproduction and inventory costs. Push systems rely on forecast-driven production schedules, which can lead to inefficiencies and slower reaction to market changes. Businesses aiming for agile supply chains often prefer pull systems to quickly adapt to fluctuating demand patterns.

Implementation Challenges and Solutions

Push systems often face challenges such as inaccurate demand forecasting leading to overproduction and increased inventory costs. Implementing advanced analytics and real-time data integration can help improve demand forecasting accuracy and align production with actual customer needs. Pull systems encounter difficulties like slower response times and dependency on supplier reliability, which can be mitigated by establishing strong supplier relationships and adopting flexible manufacturing processes.

Real-world Applications in Manufacturing

Push systems in manufacturing rely on forecast-driven production schedules, commonly used in industries like automotive and electronics where high-volume, standardized output is essential. Pull systems, such as Just-In-Time (JIT) implemented by Toyota, respond to actual demand, reducing inventory costs and minimizing waste in lean manufacturing environments. Manufacturers often combine both systems to balance efficiency, flexibility, and responsiveness to fluctuating market demands.

Choosing the Right System for Your Operation

Selecting the optimal production system hinges on factors such as demand variability, inventory costs, and lead times. A push system suits operations with stable demand and allows for efficient bulk production and inventory buildup, whereas a pull system minimizes waste and enhances responsiveness by producing only what is needed based on actual customer demand. Evaluating your supply chain flexibility and workforce capacity will guide the choice between these two systems to maximize efficiency and customer satisfaction.

Kanban

Kanban is a pull system that uses visual signals to control work in progress, improving efficiency and reducing waste compared to traditional push systems.

Just-In-Time (JIT)

Just-In-Time (JIT) manufacturing uses a pull system to minimize inventory and reduce waste by producing only what is needed when it is needed.

Drum-Buffer-Rope (DBR)

Drum-Buffer-Rope (DBR) optimizes production by using a pull system to pace workflow based on the bottleneck resource (drum), protect it with a time buffer, and synchronize upstream processes through the rope to prevent overproduction and reduce inventory.

Material Requirements Planning (MRP)

Material Requirements Planning (MRP) uses a push system by scheduling production based on forecasted demand and planned orders to ensure timely inventory availability.

Production Leveling (Heijunka)

Production Leveling (Heijunka) optimizes pull systems by smoothing production schedules to reduce waste and improve flow, unlike push systems that schedule based on forecasted demand causing variability and overproduction.

Demand-Driven Replenishment

Demand-driven replenishment prioritizes pull systems by triggering inventory restocking based on real-time customer demand, reducing excess stock and improving supply chain responsiveness compared to traditional push systems.

CONWIP (Constant Work-In-Process)

CONWIP (Constant Work-In-Process) combines push and pull system advantages by maintaining a fixed inventory level to control workflow and optimize production efficiency.

Lead Time Reduction

Pull systems significantly reduce lead time by producing goods only in response to actual demand, minimizing work-in-progress and inventory delays compared to push systems that forecast and push products through the supply chain.

Batch Processing

The push system in batch processing schedules tasks based on predetermined timelines, while the pull system triggers processing only when downstream demand or capacity signals are received.

Flow Shop Scheduling

Push systems in Flow Shop Scheduling pre-schedule production based on forecasted demand, whereas pull systems dynamically adjust production based on actual consumption to minimize work-in-progress and reduce lead times.

push system vs pull system Infographic

njnir.com

njnir.com