Flexible Manufacturing Systems (FMS) offer adaptability by allowing quick changes in production processes, enabling manufacturers to respond efficiently to varying product demands and customization needs. Dedicated Manufacturing Lines are optimized for high-volume production of a single product, providing cost efficiency and consistent quality but with limited flexibility. Choosing between FMS and Dedicated Lines depends on balancing the need for product variety against the advantages of operational efficiency and reduced setup times.

Table of Comparison

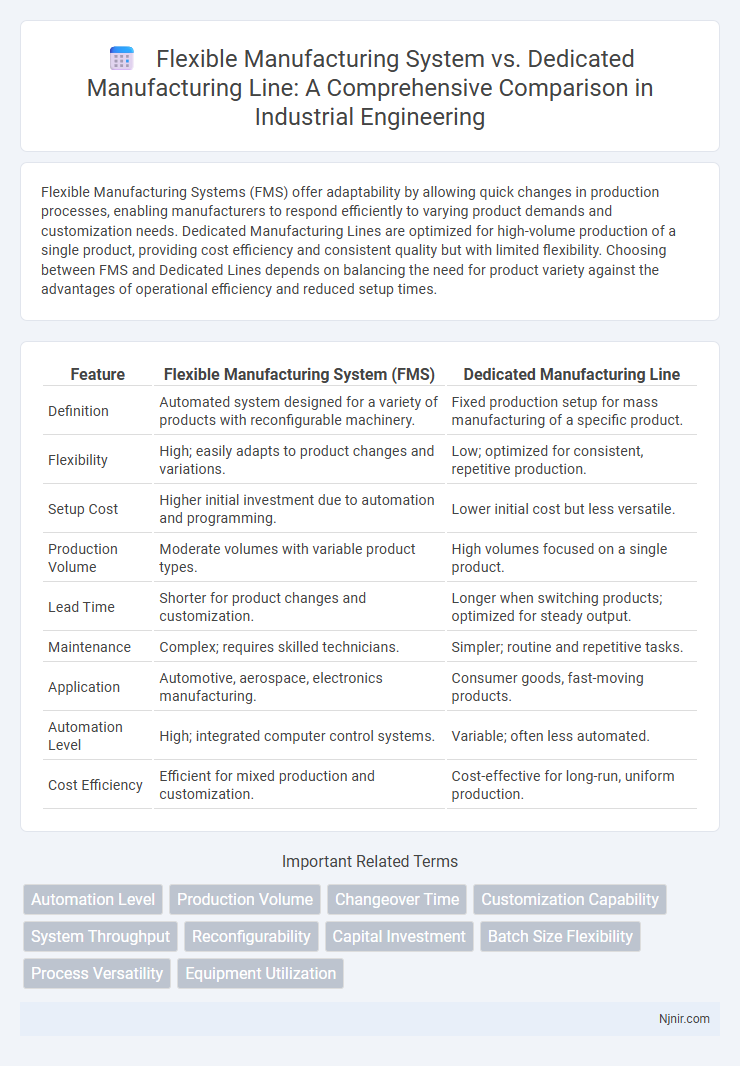

| Feature | Flexible Manufacturing System (FMS) | Dedicated Manufacturing Line |

|---|---|---|

| Definition | Automated system designed for a variety of products with reconfigurable machinery. | Fixed production setup for mass manufacturing of a specific product. |

| Flexibility | High; easily adapts to product changes and variations. | Low; optimized for consistent, repetitive production. |

| Setup Cost | Higher initial investment due to automation and programming. | Lower initial cost but less versatile. |

| Production Volume | Moderate volumes with variable product types. | High volumes focused on a single product. |

| Lead Time | Shorter for product changes and customization. | Longer when switching products; optimized for steady output. |

| Maintenance | Complex; requires skilled technicians. | Simpler; routine and repetitive tasks. |

| Application | Automotive, aerospace, electronics manufacturing. | Consumer goods, fast-moving products. |

| Automation Level | High; integrated computer control systems. | Variable; often less automated. |

| Cost Efficiency | Efficient for mixed production and customization. | Cost-effective for long-run, uniform production. |

Introduction to Manufacturing Systems

Flexible Manufacturing Systems (FMS) enable adaptability in production by integrating computer-controlled machines and automated material handling, allowing quick changes in product types without extensive reconfiguration. Dedicated Manufacturing Lines focus on high-volume, repetitive production of a specific product with specialized equipment, optimizing efficiency and reducing per-unit cost but lacking versatility. Understanding these systems is crucial for selecting the appropriate manufacturing strategy based on product variety, volume, and lead time requirements.

Overview of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) consist of integrated workstations controlled by a central computer, allowing automated production of varied products with minimal manual intervention. These systems optimize resource utilization, improve production flexibility, and reduce downtime by quickly adapting to changes in product design or volume. FMS is ideal for industries requiring efficient handling of low to medium volume production runs with frequent product variations, unlike Dedicated Manufacturing Lines designed for high-volume, single-product runs.

Dedicated Manufacturing Lines Explained

Dedicated manufacturing lines optimize production by focusing on a single product or limited product range, resulting in higher efficiency, consistent quality, and reduced setup times. These lines use specialized machinery and processes tailored to specific products, enabling faster production cycles and lower per-unit costs. Ideal for high-volume production, dedicated lines minimize downtime and simplify maintenance due to their streamlined design.

Key Differences Between FMS and Dedicated Lines

Flexible Manufacturing Systems (FMS) offer versatility by handling multiple product types and quick changeovers, whereas Dedicated Manufacturing Lines specialize in producing a single product with high efficiency and lower unit costs. FMS integrates automated machines, robots, and computer control, enabling adaptability to varying production volumes and product designs, while dedicated lines rely on specialized, fixed tooling optimized for mass production. The primary trade-off involves FMS's higher initial investment and complex setup against dedicated lines' streamlined processes and optimized throughput for uniform product output.

Flexibility and Adaptability in Production

Flexible Manufacturing Systems (FMS) offer superior adaptability by allowing rapid reconfiguration for diverse product types and volumes, reducing downtime and increasing responsiveness to market changes. Dedicated Manufacturing Lines excel in high-volume, consistent production but lack the flexibility to quickly switch between products, leading to potential inefficiencies when demand fluctuates. Investing in FMS enhances production agility through modular equipment and programmable controls, enabling manufacturers to meet varying customer requirements more effectively than fixed dedicated lines.

Cost Implications and Investment Considerations

Flexible Manufacturing Systems (FMS) demand higher initial capital investment due to advanced automation and adaptability, but reduce long-term operational costs through versatile production capabilities and minimized changeover times. Dedicated Manufacturing Lines require lower upfront expenditure but incur higher costs from limited flexibility, increased downtime, and expensive retooling when shifting product lines. Investment considerations must balance the cost efficiency of FMS in multi-product environments against the cost predictability of dedicated lines for high-volume, single-product manufacturing.

Productivity and Throughput Comparison

Flexible Manufacturing Systems (FMS) offer higher adaptability and can handle a variety of products without significant downtime, resulting in improved overall productivity for small to medium batch sizes. Dedicated Manufacturing Lines typically achieve superior throughput rates for high-volume, repetitive production due to optimized, specialized machinery and streamlined workflows. The trade-off between FMS and dedicated lines hinges on the balance between production volume demands and the need for product variety flexibility.

Suitability for Product Variety and Volume

Flexible Manufacturing Systems (FMS) excel in handling high product variety with moderate to low production volumes by quickly adapting to different designs and specifications. Dedicated Manufacturing Lines are optimized for high volume, low variety production, ensuring efficiency and consistency for standardized products. Businesses requiring rapid product changes benefit from FMS, while those prioritizing scale and unit cost reduction prefer dedicated lines.

Technological Integration and Automation

Flexible Manufacturing Systems (FMS) incorporate advanced technological integration through programmable automation, allowing rapid adaptation to different product types and volumes with minimal downtime. Dedicated Manufacturing Lines utilize fixed automation optimized for high-volume, repetitive production, offering superior efficiency and consistency but limited flexibility. The integration of IoT sensors and AI-driven control in FMS enhances real-time monitoring and decision-making, whereas dedicated lines emphasize streamlined, specialized automation with fewer variables to manage.

Future Trends in Manufacturing Systems

Flexible Manufacturing Systems (FMS) are increasingly favored for their adaptability to produce a variety of products with minimal downtime, leveraging advanced robotics and AI-driven process optimization. Dedicated Manufacturing Lines excel in high-volume production efficiency but face challenges integrating Industry 4.0 technologies at scale, potentially limiting future scalability. Emerging trends emphasize hybrid systems that combine FMS flexibility with dedicated line productivity, driven by real-time data analytics and digital twin simulations to enhance responsiveness and operational efficiency.

Automation Level

Flexible Manufacturing Systems offer higher automation levels with programmable machinery enabling versatile production, whereas Dedicated Manufacturing Lines feature fixed automation optimized for high-volume, repetitive tasks.

Production Volume

Flexible Manufacturing Systems efficiently handle low to medium production volumes with high variety, while Dedicated Manufacturing Lines excel in high production volumes with consistent product output.

Changeover Time

Flexible Manufacturing Systems reduce changeover time significantly compared to Dedicated Manufacturing Lines by enabling rapid reconfiguration for different product types.

Customization Capability

Flexible Manufacturing Systems offer superior customization capability by enabling rapid adaptation to varying product designs, unlike Dedicated Manufacturing Lines which are optimized for high-volume production but lack versatility.

System Throughput

Flexible manufacturing systems achieve higher system throughput by adapting to variable product types, whereas dedicated manufacturing lines optimize throughput for a single product with minimal changeover time.

Reconfigurability

Flexible Manufacturing Systems offer superior reconfigurability by enabling rapid adaptation to product changes, unlike Dedicated Manufacturing Lines designed for fixed, high-volume production with limited adaptability.

Capital Investment

Flexible Manufacturing Systems require higher initial capital investment due to advanced automation and adaptability, while Dedicated Manufacturing Lines demand lower upfront costs but offer limited versatility.

Batch Size Flexibility

Flexible Manufacturing Systems enable efficient production of varying batch sizes, whereas Dedicated Manufacturing Lines are optimized for large, consistent batch sizes with minimal variability.

Process Versatility

Flexible Manufacturing Systems offer superior process versatility by enabling rapid adaptation to different products through programmable automation, whereas Dedicated Manufacturing Lines prioritize high efficiency and output for a single product with limited flexibility.

Equipment Utilization

Flexible Manufacturing Systems optimize equipment utilization by enabling quick changeovers and multi-product processing, whereas Dedicated Manufacturing Lines often achieve higher utilization rates for single-product runs due to specialized, consistent setups.

Flexible Manufacturing System vs Dedicated Manufacturing Line Infographic

njnir.com

njnir.com