Single-minute exchange of dies (SMED) is a lean manufacturing technique aimed at reducing setup times to less than 10 minutes by separating internal and external setup activities and streamlining processes. Quick changeover encompasses a broader range of strategies designed to minimize downtime during equipment changeovers, focusing on efficiency and flexibility across various manufacturing operations. Both methods improve production responsiveness and reduce waste, but SMED specifically targets die changes within presses, while quick changeover applies to diverse machine setups.

Table of Comparison

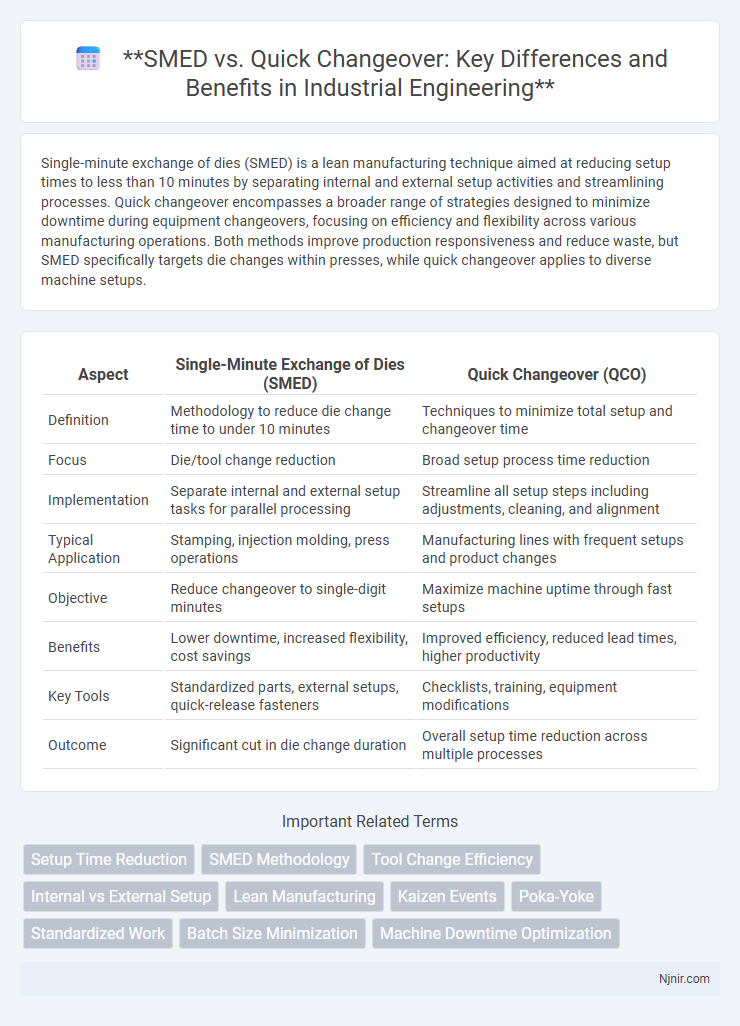

| Aspect | Single-Minute Exchange of Dies (SMED) | Quick Changeover (QCO) |

|---|---|---|

| Definition | Methodology to reduce die change time to under 10 minutes | Techniques to minimize total setup and changeover time |

| Focus | Die/tool change reduction | Broad setup process time reduction |

| Implementation | Separate internal and external setup tasks for parallel processing | Streamline all setup steps including adjustments, cleaning, and alignment |

| Typical Application | Stamping, injection molding, press operations | Manufacturing lines with frequent setups and product changes |

| Objective | Reduce changeover to single-digit minutes | Maximize machine uptime through fast setups |

| Benefits | Lower downtime, increased flexibility, cost savings | Improved efficiency, reduced lead times, higher productivity |

| Key Tools | Standardized parts, external setups, quick-release fasteners | Checklists, training, equipment modifications |

| Outcome | Significant cut in die change duration | Overall setup time reduction across multiple processes |

Introduction to SMED and Quick Changeover

Single-Minute Exchange of Dies (SMED) is a lean manufacturing technique aimed at reducing equipment setup times to under 10 minutes, enhancing production efficiency and flexibility. Quick changeover refers broadly to methods that minimize downtime during machine or process transitions, encompassing SMED as a specific, structured approach. Implementing SMED involves distinguishing internal and external setup tasks, streamlining workflows to enable rapid changeovers without sacrificing quality or safety.

Defining Single-Minute Exchange of Dies (SMED)

Single-Minute Exchange of Dies (SMED) is a methodology aimed at reducing equipment setup times to less than 10 minutes, focusing on streamlining and separating internal and external setup activities. This technique enhances production efficiency by minimizing downtime during tool or die changes without compromising quality. Unlike general quick changeover processes, SMED emphasizes converting internal setup tasks, which require machine stoppage, into external tasks performed while the machine is running.

Understanding Quick Changeover Techniques

Single-minute exchange of dies (SMED) is a lean manufacturing method specifically aimed at reducing die change times to under 10 minutes, enhancing production efficiency. Quick changeover techniques encompass a broader range of strategies designed to minimize setup times across various equipment beyond dies, including standardized tools, parallel operations, and streamlined workflows. Understanding quick changeover techniques involves analyzing process steps to separate internal and external tasks, allowing simultaneous preparation and drastically reducing downtime in manufacturing environments.

Historical Development and Evolution

Single-minute exchange of dies (SMED) was pioneered by Shigeo Shingo in the 1950s to drastically reduce die changeover times from hours to minutes, revolutionizing manufacturing efficiency. The concept evolved from initial internal and external setup distinction to a structured methodology that minimized setup waste. Quick changeover techniques have since expanded beyond dies to include tools, molds, and fixtures, integrating lean manufacturing principles and digital automation for continuous process improvement.

Key Principles of SMED

Single-Minute Exchange of Dies (SMED) emphasizes reducing setup times to less than 10 minutes by separating internal and external setup activities, standardizing procedures, and streamlining operations. Key principles include converting internal setup tasks (requiring machine stoppage) into external tasks (performed while the machine runs), organizing tools and parts for immediate access, and simplifying adjustments to minimize downtime. SMED's focus on rapid changeover enhances manufacturing flexibility, reduces inventory costs, and improves overall equipment effectiveness (OEE) compared to general quick changeover methods.

Benefits of Quick Changeover Processes

Quick changeover processes significantly enhance manufacturing efficiency by drastically reducing downtime between production runs, enabling faster response to market demands and smaller batch sizes. They improve overall equipment effectiveness (OEE) and increase flexibility, allowing manufacturers to switch products seamlessly without sacrificing quality. These processes lead to lower inventory costs and higher throughput, fostering a leaner, more agile production environment.

SMED vs Quick Changeover: Core Differences

Single-Minute Exchange of Dies (SMED) emphasizes reducing setup times to under 10 minutes by meticulously analyzing and separating internal and external tasks, whereas Quick Changeover broadly aims to minimize downtime without a strict time target. SMED provides a structured methodology with specific steps, such as converting internal tasks to external ones and streamlining all processes, while Quick Changeover often refers to any effort to speed up equipment changeover. The core difference lies in SMED's detailed, step-by-step approach focused on achieving single-digit minute setups compared to the more general, goal-oriented nature of Quick Changeover practices.

Implementation Steps and Best Practices

Single-minute exchange of dies (SMED) focuses on reducing setup times to under 10 minutes by separating internal and external setup tasks and streamlining each step. Quick changeover similarly aims to minimize downtime by standardizing procedures, utilizing modular tools, and organizing workspace efficiently to achieve faster transitions between processes. Best practices include thorough training, continuous measurement of setup times, implementing visual aids, and fostering a culture of continuous improvement for sustained effectiveness.

Challenges and Common Pitfalls

Single-minute exchange of dies (SMED) and quick changeover both aim to reduce setup times, but SMED specifically targets minimizing die change duration to under 10 minutes, which can be technically challenging due to complex die handling and precision requirements. Common pitfalls include inadequate preparation, insufficient training, and failure to standardize procedures, leading to inconsistent changeover times and increased downtime. Organizations often struggle with identifying internal versus external setup tasks, causing inefficiencies and undermining the benefits of both SMED and quick changeover methodologies.

Case Studies: Real-World Industrial Applications

Single-minute exchange of dies (SMED) and quick changeover techniques significantly reduce equipment downtime in manufacturing, as demonstrated by Toyota's implementation that cut changeover times from hours to under 10 minutes. Industry examples, such as Bosch and Caterpillar, reveal 40-70% productivity gains through structured SMED methodologies, minimizing production delays and increasing flexibility. Case studies highlight how integrating quick changeover processes enhances lean manufacturing, reduces setup waste, and improves overall equipment effectiveness (OEE) in sectors like automotive and heavy machinery.

Setup Time Reduction

Single-minute exchange of dies (SMED) focuses on reducing setup time to under 10 minutes, while quick changeover encompasses various techniques aimed at minimizing overall setup duration to enhance manufacturing efficiency.

SMED Methodology

Single-minute exchange of dies (SMED) methodology reduces manufacturing setup times to under 10 minutes by systematically separating internal and external setup tasks, while quick changeover broadly refers to any approach aimed at minimizing equipment adjustment durations.

Tool Change Efficiency

Single-minute exchange of dies (SMED) optimizes tool change efficiency by reducing setup time to under 10 minutes, whereas quick changeover focuses more broadly on minimizing total equipment downtime during tool replacement.

Internal vs External Setup

Single-minute exchange of dies (SMED) minimizes internal setup time by converting tasks to external setup, whereas quick changeover emphasizes reducing total changeover time through efficient coordination of both internal and external activities.

Lean Manufacturing

Single-minute exchange of dies (SMED) is a Lean Manufacturing technique that reduces machine setup times to under 10 minutes, directly enhancing production flexibility and efficiency compared to general quick changeover methods.

Kaizen Events

Kaizen Events streamline Single-minute Exchange of Dies (SMED) by reducing setup times through systematic analysis and implementation of quick changeover techniques.

Poka-Yoke

Single-minute exchange of dies (SMED) significantly reduces setup times by separating internal and external tasks, while Quick Changeover focuses on minimizing downtime through streamlined processes, with both methods leveraging Poka-Yoke to prevent errors and ensure consistent, error-free transitions.

Standardized Work

Single-minute exchange of dies (SMED) standardizes work processes to reduce setup times, enhancing efficiency more effectively than general quick changeover methods by emphasizing detailed task analysis and elimination of internal setup steps.

Batch Size Minimization

Single-minute exchange of dies (SMED) significantly reduces batch size by minimizing setup times, enabling faster changeovers compared to traditional quick changeover methods.

Machine Downtime Optimization

Single-minute exchange of dies (SMED) significantly reduces machine downtime by enabling faster tool changeovers compared to general quick changeover techniques, optimizing production efficiency and minimizing idle time.

Single-minute exchange of dies vs Quick changeover Infographic

njnir.com

njnir.com