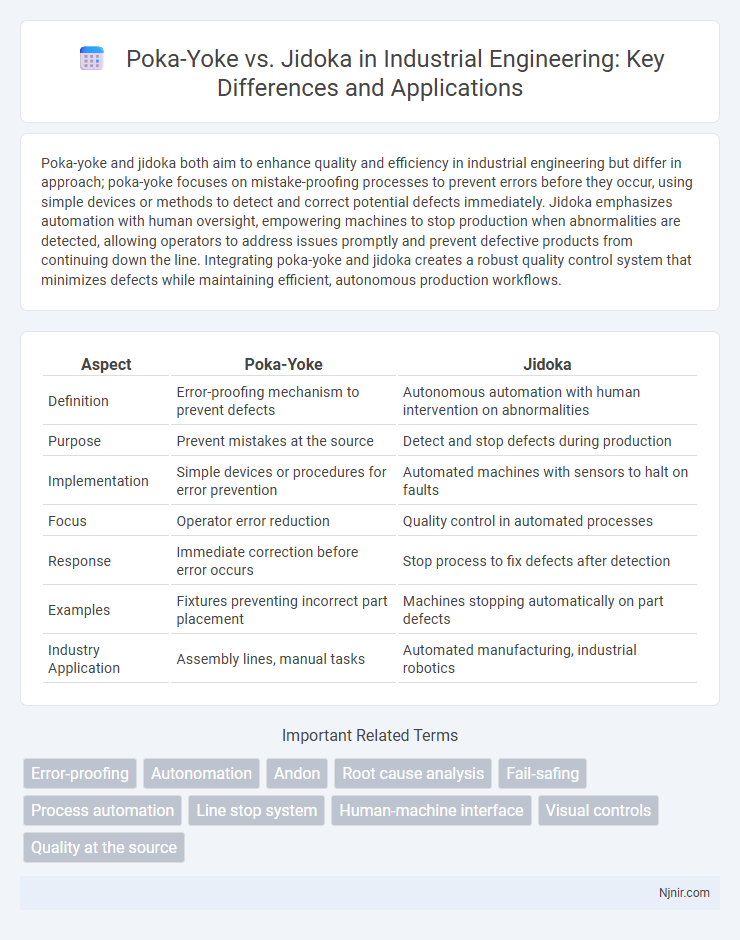

Poka-yoke and jidoka both aim to enhance quality and efficiency in industrial engineering but differ in approach; poka-yoke focuses on mistake-proofing processes to prevent errors before they occur, using simple devices or methods to detect and correct potential defects immediately. Jidoka emphasizes automation with human oversight, empowering machines to stop production when abnormalities are detected, allowing operators to address issues promptly and prevent defective products from continuing down the line. Integrating poka-yoke and jidoka creates a robust quality control system that minimizes defects while maintaining efficient, autonomous production workflows.

Table of Comparison

| Aspect | Poka-Yoke | Jidoka |

|---|---|---|

| Definition | Error-proofing mechanism to prevent defects | Autonomous automation with human intervention on abnormalities |

| Purpose | Prevent mistakes at the source | Detect and stop defects during production |

| Implementation | Simple devices or procedures for error prevention | Automated machines with sensors to halt on faults |

| Focus | Operator error reduction | Quality control in automated processes |

| Response | Immediate correction before error occurs | Stop process to fix defects after detection |

| Examples | Fixtures preventing incorrect part placement | Machines stopping automatically on part defects |

| Industry Application | Assembly lines, manual tasks | Automated manufacturing, industrial robotics |

Introduction to Poka-Yoke and Jidoka

Poka-Yoke, a Japanese term meaning "mistake-proofing," is a quality management technique designed to prevent errors by implementing simple, effective mechanisms during the manufacturing process. Jidoka, or "automation with a human touch," emphasizes instilling intelligent automation systems that detect abnormalities and halt production to address issues immediately. Both concepts originated from the Toyota Production System and play crucial roles in enhancing operational efficiency and reducing defects in lean manufacturing.

Historical Background and Evolution

Poka-yoke, introduced by Shigeo Shingo in the 1960s, evolved as a mistake-proofing method to eliminate errors in manufacturing processes, enhancing quality control at the source. Jidoka, originating from Toyota's early 20th-century production system, empowered machines and operators to detect abnormalities and halt processes immediately to prevent defects. Both concepts have significantly shaped lean manufacturing by embedding quality assurance into production workflows and continuous improvement practices.

Core Principles of Poka-Yoke

Poka-yoke centers on mistake-proofing by designing processes and tools to prevent errors before they occur, emphasizing simple, low-cost devices that detect and correct deviations immediately. Core principles include error detection at the source, elimination of defects through automatic feedback, and ensuring operator awareness without relying on human memory or vigilance. Unlike jidoka, which integrates automation with human judgment to stop production when abnormalities arise, poka-yoke focuses specifically on proactive error prevention mechanisms embedded within the workflow.

Core Principles of Jidoka

Jidoka centers on the principle of autonomation, empowering machines and operators to detect abnormalities immediately and halt production to prevent defects. Its core principles emphasize intelligent automation, real-time problem identification, and enabling human intervention for quality assurance. This approach enhances manufacturing efficiency by ensuring issues are addressed promptly, minimizing waste and downtime.

Key Differences Between Poka-Yoke and Jidoka

Poka-Yoke is a mistake-proofing technique designed to prevent errors at the source by implementing simple, low-cost devices or methods, whereas Jidoka focuses on automating quality control by stopping the production process when abnormalities occur. Poka-Yoke ensures error prevention during operation, while Jidoka enables immediate detection and correction of defects, enhancing overall process control and worker autonomy. The primary difference lies in Poka-Yoke's prevention of human error through physical or procedural safeguards, contrasted with Jidoka's automated intervention to maintain quality standards during manufacturing.

Implementation Techniques in Industrial Settings

Poka-yoke implementation techniques in industrial settings primarily involve error-proofing devices such as sensors, alarms, and physical constraints designed to detect and prevent defects at the source. Jidoka focuses on automation with a human touch, incorporating mechanisms that stop the production line automatically when abnormalities occur, allowing operators to address issues immediately. Both techniques improve quality control, with poka-yoke emphasizing defect prevention and jidoka enabling real-time problem-solving for continuous improvement.

Impact on Quality Assurance and Defect Reduction

Poka-yoke enhances quality assurance by implementing simple, fail-safe mechanisms to prevent errors at the source, drastically reducing defect rates in manufacturing processes. Jidoka empowers workers and machines to detect abnormalities immediately, stopping production to address issues before defective products advance further. Combining poka-yoke's error-proofing with jidoka's real-time problem identification results in robust defect prevention and continuous quality improvement in production systems.

Case Studies: Poka-Yoke and Jidoka in Action

Case studies highlight Poka-Yoke as an error-proofing method implemented in Toyota's assembly line, drastically reducing defects by using simple mistake-proof devices like color-coded fixtures. Jidoka, exemplified by the Andon system at Toyota, empowers workers to halt production immediately upon detecting abnormalities, ensuring quality control and swift problem resolution. Both techniques synergize to elevate manufacturing efficiency and product quality, demonstrating their vital roles in lean production environments.

Challenges and Best Practices

Poka-yoke challenges include designing effective error-proofing mechanisms that do not disrupt workflow, while jidoka faces difficulties integrating automation with human intervention for quality control. Best practices for poka-yoke emphasize simplicity and immediate feedback to prevent defects at the source, whereas jidoka requires continuous monitoring and empowering operators to halt production when abnormalities arise. Combining these approaches enhances overall quality by addressing both error prevention and autonomous problem resolution in manufacturing processes.

Future Trends in Error Proofing and Automation

Poka-yoke and jidoka are evolving with the integration of advanced technologies such as AI, IoT, and machine learning to enhance error proofing and automation precision. Future trends emphasize real-time data analytics and predictive maintenance, enabling systems to autonomously detect and correct defects before they occur. The convergence of smart sensors and cyber-physical systems is driving a shift toward more adaptive, self-correcting manufacturing environments that maximize efficiency and minimize human intervention.

Error-proofing

Poka-yoke employs simple, automated error-proofing techniques to prevent defects in manufacturing processes, while jidoka integrates automatic error detection with immediate machine stoppage to enhance quality control and prevent defect escalation.

Autonomation

Poka-yoke implements simple error-proofing techniques to prevent mistakes at the source, while jidoka--also known as autonomation--integrates automated detection of defects with immediate halting of production to ensure quality control and empower workers to address issues promptly.

Andon

Andon systems serve as a critical poka-yoke tool by visually signaling defects or abnormalities on the production line, enabling immediate jidoka actions to stop the process and ensure quality control.

Root cause analysis

Poka-yoke prevents errors by designing fail-safes to stop mistakes at the source, while jidoka empowers machines and operators to detect abnormalities and halt production for immediate root cause analysis and corrective action.

Fail-safing

Poka-yoke implements fail-safing by preventing errors at the source through simple, low-cost devices, while jidoka emphasizes fail-safing by automatically detecting defects and stopping production to enable immediate correction.

Process automation

Poka-yoke enhances process automation by preventing errors through simple fail-safes, whereas jidoka focuses on automated defect detection and immediate process halt to ensure quality control.

Line stop system

Poka-yoke implements simple error-proofing devices to prevent defects before they occur, while jidoka integrates immediate line stop mechanisms triggered by detecting abnormalities to ensure quality control during production.

Human-machine interface

Poka-yoke enhances the human-machine interface by preventing operator errors through simple, mistake-proofing devices, while jidoka empowers machines to autonomously detect abnormalities and halt operations, ensuring quality control with minimal human intervention.

Visual controls

Poka-yoke uses simple visual controls to prevent errors at the source, while jidoka employs visual signals to detect and stop defects during production for immediate corrective action.

Quality at the source

Poka-yoke prevents defects by error-proofing processes at the source, while jidoka empowers machines and operators to detect and stop abnormalities immediately to ensure quality at the source.

poka-yoke vs jidoka Infographic

njnir.com

njnir.com