Digital workflows in industrial engineering streamline processes by enabling real-time data access, reducing errors, and improving collaboration across teams. Paper-based workflows often suffer from inefficiencies such as lost documents, delayed communication, and limited traceability. Transitioning to digital systems enhances productivity, accelerates decision-making, and supports sustainable, eco-friendly operations.

Table of Comparison

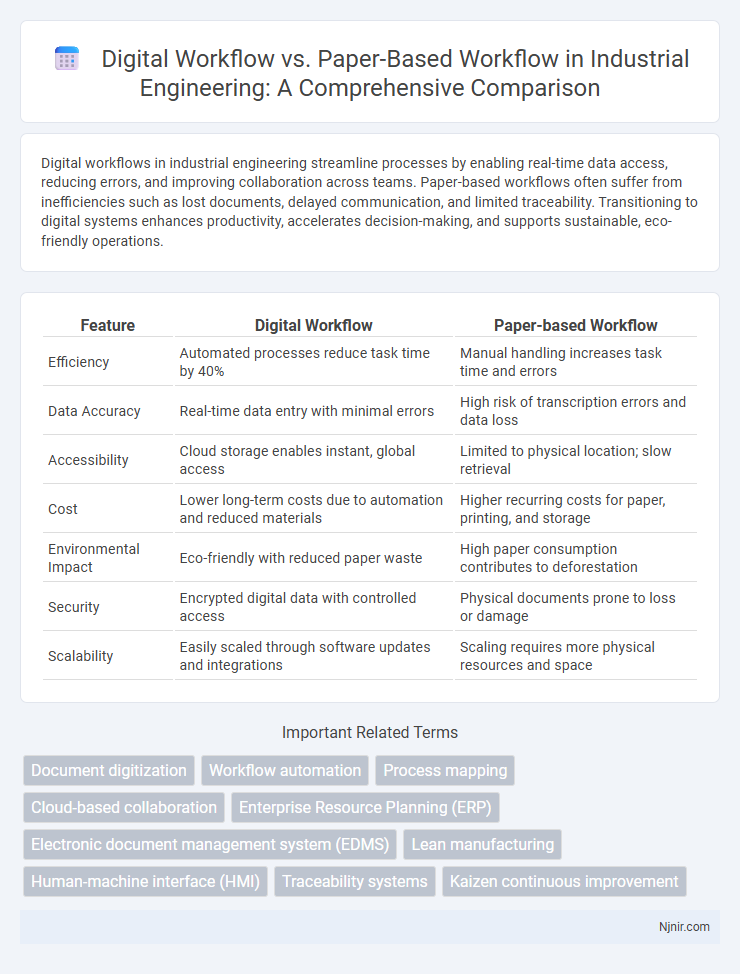

| Feature | Digital Workflow | Paper-based Workflow |

|---|---|---|

| Efficiency | Automated processes reduce task time by 40% | Manual handling increases task time and errors |

| Data Accuracy | Real-time data entry with minimal errors | High risk of transcription errors and data loss |

| Accessibility | Cloud storage enables instant, global access | Limited to physical location; slow retrieval |

| Cost | Lower long-term costs due to automation and reduced materials | Higher recurring costs for paper, printing, and storage |

| Environmental Impact | Eco-friendly with reduced paper waste | High paper consumption contributes to deforestation |

| Security | Encrypted digital data with controlled access | Physical documents prone to loss or damage |

| Scalability | Easily scaled through software updates and integrations | Scaling requires more physical resources and space |

Introduction to Workflow Systems in Industrial Engineering

Digital workflows in industrial engineering utilize automated software systems to enhance process efficiency, accuracy, and real-time data tracking, significantly reducing errors and delays compared to traditional paper-based workflows. Paper-based workflows rely on manual documentation and physical handling, which often lead to slower communication, increased risk of data loss, and limited traceability across production stages. Implementing digital workflow systems enables seamless integration of task management, resource allocation, and quality control, driving productivity and operational optimization in complex industrial environments.

Defining Digital and Paper-Based Workflows

Digital workflows automate and streamline tasks through software applications, enabling real-time collaboration, data integration, and enhanced efficiency. Paper-based workflows rely on physical documents and manual processes, often leading to slower task completion and increased risk of errors or loss. Defining digital workflows involves outlining systematic processes powered by technology, while paper-based workflows center on traditional, tangible document handling methods.

Key Process Differences: Digital vs Paper-Based

Digital workflows enable real-time collaboration, automated data entry, and seamless integration with cloud-based applications, significantly reducing processing time and errors. Paper-based workflows rely on manual data handling, physical document storage, and often result in slower communication and increased risk of misplacement or damage. The digital approach supports traceability and audit trails, whereas paper workflows lack efficient tracking and version control.

Efficiency and Productivity Comparison

Digital workflows significantly enhance efficiency by automating repetitive tasks and enabling real-time collaboration, reducing the time spent on manual data entry and minimizing errors common in paper-based workflows. Paper-based systems often result in slower process completion due to physical document handling, increased risk of loss, and difficulty in tracking progress, which hampers overall productivity. Implementation of digital workflows leads to measurable improvements in task turnaround time, resource allocation, and workflow transparency, driving higher organizational productivity levels.

Impact on Quality and Error Reduction

Digital workflows significantly improve quality and reduce errors by automating tasks, ensuring data accuracy, and enabling real-time collaboration across teams. Paper-based workflows often lead to manual entry errors, misfiled documents, and slower error detection, negatively impacting quality assurance. Implementing digital systems enhances compliance tracking and audit trails, fostering consistent and reliable process outcomes.

Cost Implications: Digital vs Paper-Based Workflows

Digital workflows significantly reduce costs by minimizing paper usage, printing expenses, and physical storage requirements, leading to long-term savings for businesses. Automated processes in digital workflows also decrease labor costs by streamlining data entry and reducing errors compared to manual, paper-based methods. While initial investments in digital tools and software exist, the overall operational efficiency and reduced resource consumption make digital workflows more cost-effective than traditional paper-based workflows.

Data Security and Compliance Considerations

Digital workflows enhance data security through encryption, access controls, and audit trails, reducing the risk of unauthorized access and data breaches common in paper-based workflows. Compliance with regulations like GDPR and HIPAA is more efficiently maintained using digital systems that automate data retention policies and provide real-time monitoring. Paper-based workflows face challenges in ensuring secure document handling, increasing vulnerability to loss, theft, and compliance violations.

Environmental Sustainability of Workflow Choices

Digital workflows significantly reduce paper consumption, leading to lower deforestation rates and decreased greenhouse gas emissions associated with paper production and disposal. Energy-efficient cloud computing and electronic data management minimize environmental footprints compared to the resource-intensive processes of printing, copying, and transporting paper documents. Transitioning to digital workflows supports sustainable business practices by lowering waste generation and promoting efficient resource utilization.

Implementation Challenges and Transition Strategies

Implementing digital workflows often faces challenges such as employee resistance, high initial costs, and integration complexities with existing systems. Transition strategies emphasize phased adoption, comprehensive training programs, and continuous support to minimize disruption and ensure user proficiency. Organizations leveraging cloud-based solutions and automation tools experience smoother shifts compared to fully manual, paper-dependent operations.

Future Trends in Industrial Workflow Management

Digital workflow systems leverage AI integration, IoT connectivity, and cloud-based platforms to enable real-time process optimization and data-driven decision-making in industrial workflow management. Paper-based workflows lack scalability and real-time visibility, making them less adaptable to Industry 4.0 demands and smart factory environments. Future trends indicate widespread adoption of automated, digital workflows with enhanced security protocols and predictive analytics to increase operational efficiency and reduce downtime.

Document digitization

Digital workflows enhance efficiency and accuracy by leveraging document digitization to automate data capture, streamline approvals, and enable real-time collaboration compared to traditional paper-based workflows.

Workflow automation

Digital workflow automation enhances efficiency and accuracy by reducing manual tasks and errors compared to traditional paper-based workflows.

Process mapping

Digital workflow simplifies process mapping by enabling real-time updates, enhanced data integration, and automated task tracking compared to the manual, error-prone steps of paper-based workflow.

Cloud-based collaboration

Cloud-based collaboration in digital workflows enhances real-time communication, file sharing, and project management, significantly outperforming traditional paper-based workflows in efficiency and accessibility.

Enterprise Resource Planning (ERP)

Digital workflow integrated with Enterprise Resource Planning (ERP) enhances efficiency, accuracy, and real-time data access compared to traditional paper-based workflows.

Electronic document management system (EDMS)

Electronic Document Management Systems (EDMS) streamline digital workflows by enabling efficient document storage, retrieval, version control, and collaboration, significantly reducing errors and delays compared to traditional paper-based workflows.

Lean manufacturing

Digital workflows enhance Lean manufacturing by minimizing waste, improving process efficiency, and enabling real-time data analytics compared to traditional paper-based workflows.

Human-machine interface (HMI)

Digital workflow enhances Human-machine interface (HMI) by enabling real-time data visualization, interactive controls, and seamless integration with automated systems, unlike paper-based workflows that rely on manual data entry and static information presentation.

Traceability systems

Digital workflows enhance traceability systems by providing real-time data tracking, automated audit trails, and secure, easily accessible records compared to limited visibility and higher error rates in paper-based workflows.

Kaizen continuous improvement

Digital workflow accelerates Kaizen continuous improvement by enabling real-time data analysis, streamlined communication, and rapid process iteration compared to slower, error-prone paper-based workflows.

Digital workflow vs Paper-based workflow Infographic

njnir.com

njnir.com