Adaptive scheduling dynamically adjusts production plans based on real-time data, improving responsiveness to unexpected disruptions and demand fluctuations. Static scheduling relies on fixed plans created before production begins, offering simplicity but lacking flexibility to accommodate changes. Emphasizing adaptive scheduling enhances operational efficiency and minimizes downtime by optimizing resource allocation in industrial engineering processes.

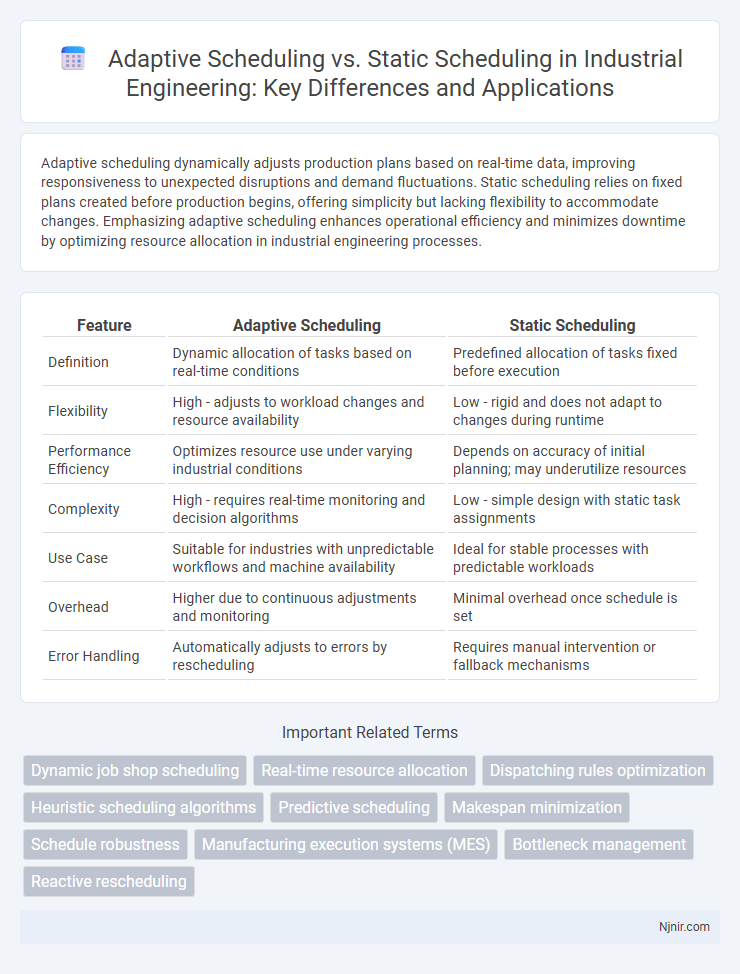

Table of Comparison

| Feature | Adaptive Scheduling | Static Scheduling |

|---|---|---|

| Definition | Dynamic allocation of tasks based on real-time conditions | Predefined allocation of tasks fixed before execution |

| Flexibility | High - adjusts to workload changes and resource availability | Low - rigid and does not adapt to changes during runtime |

| Performance Efficiency | Optimizes resource use under varying industrial conditions | Depends on accuracy of initial planning; may underutilize resources |

| Complexity | High - requires real-time monitoring and decision algorithms | Low - simple design with static task assignments |

| Use Case | Suitable for industries with unpredictable workflows and machine availability | Ideal for stable processes with predictable workloads |

| Overhead | Higher due to continuous adjustments and monitoring | Minimal overhead once schedule is set |

| Error Handling | Automatically adjusts to errors by rescheduling | Requires manual intervention or fallback mechanisms |

Introduction to Scheduling in Industrial Engineering

Adaptive scheduling dynamically adjusts production plans based on real-time data and changing shop floor conditions, enhancing flexibility and responsiveness in industrial operations. Static scheduling relies on predefined, fixed schedules that do not change during execution, suitable for stable environments with predictable tasks. Industrial engineering prioritizes adaptive scheduling to optimize resource utilization and minimize downtime amid variable manufacturing processes.

Defining Adaptive Scheduling

Adaptive scheduling dynamically adjusts task priorities and resource allocation in real-time based on system feedback and workload variations, enhancing efficiency and responsiveness. Unlike static scheduling, which assigns fixed schedules before execution, adaptive scheduling continuously monitors system performance metrics and adapts to changing conditions such as task execution times and system load. This approach is essential in environments with unpredictable workloads, enabling optimal utilization of resources and reduced latency.

Defining Static Scheduling

Static scheduling is a fixed, predetermined allocation of tasks or resources in a system, established before execution begins and remaining unchanged during runtime. It optimizes performance for predictable workloads by minimizing overhead and ensuring consistent time management. Commonly used in real-time systems, static scheduling guarantees task deadlines through precise timing and resource reservations.

Core Principles: Flexibility vs Predictability

Adaptive scheduling prioritizes flexibility by dynamically allocating tasks based on real-time system conditions, enabling efficient resource utilization and responsiveness to workload changes. Static scheduling emphasizes predictability through predefined task assignments and fixed execution timelines, ensuring consistent performance and easier analysis. The core principle difference lies in adaptive scheduling's ability to adjust to varying demands, whereas static scheduling relies on predetermined schedules for stability.

Performance Metrics Comparison

Adaptive scheduling dynamically adjusts task assignments based on real-time system states, leading to improved throughput and reduced latency compared to static scheduling, which relies on predetermined task allocation. Performance metrics such as CPU utilization and response time consistently show higher efficiency in adaptive systems, especially under variable workloads or unpredictable task arrivals. Static scheduling often results in resource underutilization and longer wait times due to its inflexible nature, highlighting the performance advantage of adaptive approaches in dynamic computing environments.

Real-Time Decision-Making in Adaptive Scheduling

Adaptive scheduling enhances real-time decision-making by dynamically adjusting task priorities and resource allocation based on current system conditions, improving responsiveness and efficiency. Unlike static scheduling, which relies on predetermined schedules, adaptive methods respond to unexpected changes such as system load variations or task arrivals, ensuring timely execution of critical tasks. This flexibility is crucial for applications requiring stringent timing constraints and high reliability, such as embedded systems and real-time computing environments.

Resource Utilization: Static vs Adaptive Approaches

Adaptive scheduling enhances resource utilization by dynamically adjusting task assignments based on real-time system states, reducing idle time and improving throughput. Static scheduling allocates resources based on predetermined plans, which may lead to underutilization or bottlenecks when workloads fluctuate. Organizations seeking optimal performance in variable environments benefit significantly from adaptive scheduling's flexibility in resource management.

Implementation Challenges and Solutions

Adaptive scheduling faces implementation challenges such as handling dynamic workload fluctuations and requiring real-time system monitoring, which increases computational overhead. Static scheduling simplifies implementation by predefining task sequences but struggles with resource utilization inefficiencies and lack of flexibility in varying conditions. Solutions include leveraging machine learning algorithms for predictive workload management in adaptive systems and employing hybrid models that combine static frameworks with on-the-fly adjustments to balance stability and responsiveness.

Industry Use Cases: Adaptive vs Static Scheduling

Adaptive scheduling enhances industrial operations by dynamically adjusting production timelines based on real-time data, improving responsiveness to demand fluctuations and equipment availability. Static scheduling relies on predefined, fixed schedules that optimize routine manufacturing processes but lack flexibility during unexpected disruptions. Industries like automotive and electronics leverage adaptive scheduling to minimize downtime and boost efficiency, while sectors with stable production lines, such as food processing, often benefit from the predictability of static scheduling.

Future Trends in Industrial Scheduling Methods

Adaptive scheduling leverages real-time data and machine learning algorithms to dynamically adjust production plans, enhancing flexibility and efficiency in complex industrial environments. Static scheduling relies on predefined, fixed schedules that lack responsiveness to unexpected disruptions, making it less suitable for modern manufacturing demands. Future trends emphasize integration of AI-driven adaptive systems with IoT connectivity, enabling predictive maintenance, demand forecasting, and optimized resource allocation to maximize productivity and minimize downtime.

Dynamic job shop scheduling

Dynamic job shop scheduling leverages adaptive scheduling techniques to optimize machine utilization and reduce job completion times by continuously adjusting job sequences in real-time, unlike static scheduling which relies on fixed, pre-determined schedules.

Real-time resource allocation

Adaptive scheduling optimizes real-time resource allocation by dynamically adjusting task priorities and resource distribution based on current system conditions, whereas static scheduling relies on pre-defined, fixed schedules that may lead to resource underutilization or delays in dynamic environments.

Dispatching rules optimization

Adaptive scheduling optimizes dispatching rules by dynamically adjusting job priorities based on real-time system states, whereas static scheduling relies on predetermined rules that do not respond to changing operational conditions.

Heuristic scheduling algorithms

Heuristic scheduling algorithms in adaptive scheduling dynamically optimize resource allocation based on real-time system feedback, outperforming static scheduling which relies on predetermined, fixed task assignments.

Predictive scheduling

Predictive scheduling uses real-time data and machine learning algorithms to dynamically adjust task allocation, enhancing efficiency and resource utilization compared to static scheduling's fixed, pre-planned task assignments.

Makespan minimization

Adaptive scheduling minimizes makespan more effectively than static scheduling by dynamically reallocating tasks based on real-time resource availability and workload variations.

Schedule robustness

Adaptive scheduling enhances schedule robustness by dynamically adjusting to disruptions and uncertainties, whereas static scheduling lacks flexibility and often results in increased delays and resource conflicts.

Manufacturing execution systems (MES)

Adaptive scheduling in Manufacturing Execution Systems (MES) dynamically adjusts production plans based on real-time data, enhancing flexibility and reducing downtime compared to static scheduling's fixed, pre-defined workflows.

Bottleneck management

Adaptive scheduling dynamically reallocates resources to address bottlenecks in real-time, significantly improving system throughput compared to static scheduling's fixed resource allocation.

Reactive rescheduling

Adaptive scheduling enables real-time reactive rescheduling by dynamically adjusting tasks based on changing conditions, unlike static scheduling which follows a fixed plan without flexibility.

Adaptive scheduling vs Static scheduling Infographic

njnir.com

njnir.com