Automated Guided Vehicles (AGVs) follow predetermined paths using physical markers or wires, making them suitable for repetitive material handling tasks in controlled environments. Autonomous Mobile Robots (AMRs) leverage advanced sensors and AI to navigate dynamically and adapt to changes in their surroundings, enhancing flexibility in complex industrial settings. The choice between AGVs and AMRs depends on factors such as facility layout, operational complexity, and scalability requirements.

Table of Comparison

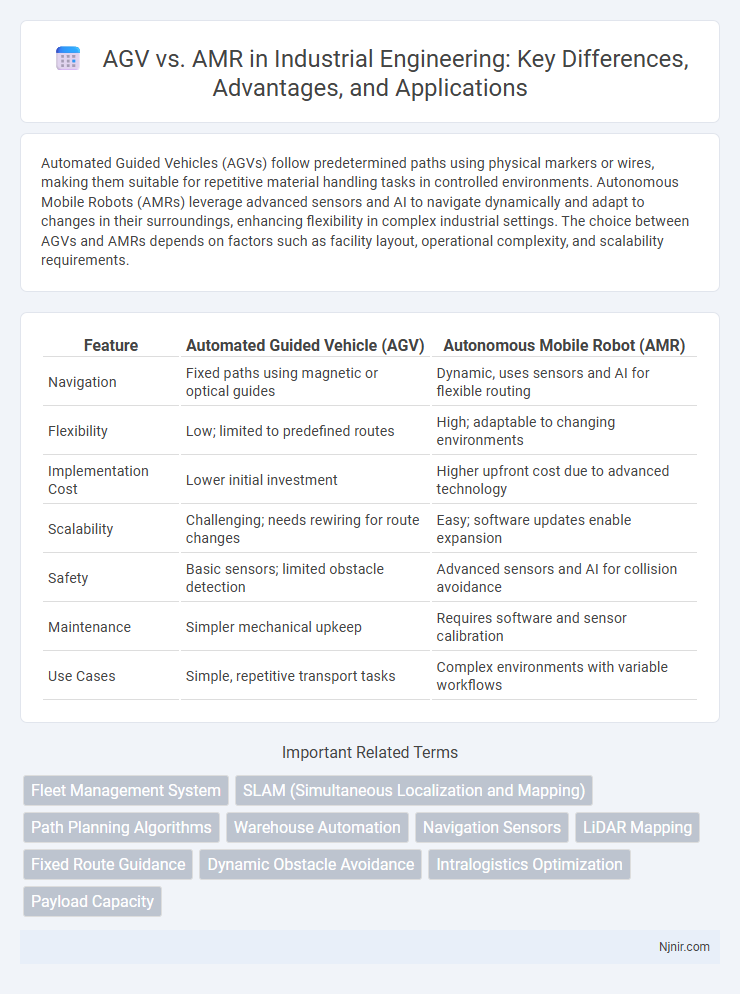

| Feature | Automated Guided Vehicle (AGV) | Autonomous Mobile Robot (AMR) |

|---|---|---|

| Navigation | Fixed paths using magnetic or optical guides | Dynamic, uses sensors and AI for flexible routing |

| Flexibility | Low; limited to predefined routes | High; adaptable to changing environments |

| Implementation Cost | Lower initial investment | Higher upfront cost due to advanced technology |

| Scalability | Challenging; needs rewiring for route changes | Easy; software updates enable expansion |

| Safety | Basic sensors; limited obstacle detection | Advanced sensors and AI for collision avoidance |

| Maintenance | Simpler mechanical upkeep | Requires software and sensor calibration |

| Use Cases | Simple, repetitive transport tasks | Complex environments with variable workflows |

Introduction to AGV and AMR Technologies

Automated Guided Vehicles (AGVs) are traditional robotic systems following fixed paths using markers or wires embedded in factory floors, primarily designed for repetitive material transport tasks. Autonomous Mobile Robots (AMRs) use advanced sensors, cameras, and AI mapping algorithms to navigate dynamic environments, allowing flexible route planning and real-time obstacle avoidance. Both technologies enhance operational efficiency in warehouses and manufacturing, but AMRs offer greater adaptability and scalability compared to AGVs due to their intelligent navigation capabilities.

Key Differences Between AGVs and AMRs

Automated Guided Vehicles (AGVs) follow fixed paths using markers or wires embedded in the floor, whereas Autonomous Mobile Robots (AMRs) navigate dynamically through complex environments using advanced sensors and AI-driven mapping. AGVs require predefined routes and external guidance systems, limiting flexibility, while AMRs adapt in real-time to obstacles and changes, enhancing operational efficiency. The integration of AMRs supports scalable automation in warehouses and manufacturing, contrasting with AGVs' reliance on structured settings for repetitive tasks.

Operational Principles of AGVs

Automated Guided Vehicles (AGVs) operate using fixed-path navigation systems such as magnetic tape, laser guidance, or wire tracks embedded in the floor, enabling precise movement along predetermined routes. Sensors and onboard controls ensure obstacle detection and safety compliance, facilitating repeatable and reliable material transport in structured environments. AGVs excel in tasks requiring consistent routing with minimal deviation, making them ideal for assembly lines and warehouses with stable layouts.

How AMRs Navigate Industrial Environments

Autonomous Mobile Robots (AMRs) use advanced sensors, such as LiDAR, cameras, and ultrasonic detectors, combined with sophisticated algorithms to map and interpret complex industrial environments. Unlike Automated Guided Vehicles (AGVs) that rely on fixed paths like magnetic tape or predefined tracks, AMRs dynamically plan and adjust their routes in real-time to avoid obstacles and optimize efficiency. This capability allows AMRs to operate flexibly in changing layouts, improving workflow automation in warehouses and manufacturing facilities.

Applications of AGV in Industrial Settings

Automated Guided Vehicles (AGVs) excel in industrial settings by efficiently transporting heavy materials and supplies across manufacturing floors, assembly lines, and warehouses, minimizing human labor and enhancing safety. They are widely used in automotive manufacturing, electronics assembly, and pharmaceutical production for repetitive tasks requiring precise navigation along fixed routes. AGVs improve workflow automation, reduce operational costs, and facilitate just-in-time inventory management by seamlessly integrating with warehouse management systems (WMS) and manufacturing execution systems (MES).

Industrial Use Cases for AMR Deployment

Autonomous Mobile Robots (AMRs) offer superior flexibility and adaptability in industrial environments compared to Automated Guided Vehicles (AGVs), enabling efficient navigation around dynamic obstacles and complex layouts. Industries utilize AMRs for tasks such as material transport, inventory management, and order fulfillment, significantly enhancing productivity and reducing labor costs. AMRs' advanced sensors and AI-driven path planning optimize workflows in warehouses, manufacturing plants, and distribution centers, making them ideal for scalable, automated industrial operations.

Advantages and Limitations of AGVs

Automated Guided Vehicles (AGVs) offer precise navigation and repeatability using fixed magnetic or optical paths, ensuring consistent material transport in controlled environments like warehouses or manufacturing floors. Advantages include high reliability, low operational complexity, and predictable routes that minimize collision risks. Limitations involve reduced flexibility due to dependence on predefined tracks, limited adaptability to dynamic obstacles, and challenges integrating with complex or rapidly changing workflows compared to Autonomous Mobile Robots (AMRs).

Benefits and Challenges of AMRs

Autonomous Mobile Robots (AMRs) offer greater flexibility and adaptability compared to Automated Guided Vehicles (AGVs) by utilizing advanced sensors and AI for dynamic navigation in complex environments, resulting in improved operational efficiency and reduced downtime. AMRs enhance scalability and ease of integration within existing workflows, supporting real-time decision-making and optimized route planning. Challenges include higher initial investment, the need for sophisticated IT infrastructure, and ongoing maintenance requirements to ensure reliable performance and cybersecurity.

Cost Analysis: AGV vs AMR Implementation

Automated Guided Vehicles (AGVs) typically require substantial upfront investment due to their reliance on fixed infrastructure such as magnetic strips or wires, leading to higher installation and maintenance costs. Autonomous Mobile Robots (AMRs) offer a more flexible, scalable solution with lower implementation costs as they employ advanced sensors and AI for navigation without dependence on physical guides. Cost analysis reveals that while AGVs may have lower operational expenses in highly structured environments, AMRs provide significant savings in dynamic settings through reduced downtime and adaptability.

Future Trends in Industrial Mobility Solutions

Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are evolving rapidly with integration of AI, advanced sensors, and real-time data analytics to enhance flexibility and efficiency in industrial mobility. Future trends indicate a shift towards AMRs leveraging cloud-based navigation systems and collaborative robotics to optimize dynamic warehouse layouts and cross-functional tasks. Increasing adoption of 5G connectivity and edge computing further enables seamless communication and predictive maintenance, driving smarter, scalable automation solutions in manufacturing and logistics.

Fleet Management System

Fleet management systems for AMRs offer dynamic route optimization and real-time coordination, outperforming traditional AGV systems that rely on fixed paths and centralized control.

SLAM (Simultaneous Localization and Mapping)

AMRs leverage advanced SLAM technology for dynamic, real-time mapping and navigation, surpassing traditional AGVs that rely on fixed paths and external guidance systems.

Path Planning Algorithms

AMRs utilize advanced AI-based path planning algorithms like SLAM and A* for dynamic, real-time navigation, while AGVs rely on fixed, pre-programmed paths using simple line-following or waypoint algorithms.

Warehouse Automation

Automated Guided Vehicles (AGVs) follow fixed paths using predefined routes and infrastructure for warehouse automation, while Autonomous Mobile Robots (AMRs) navigate dynamically with advanced sensors and AI to optimize material handling flexibility and efficiency.

Navigation Sensors

AGVs primarily rely on fixed guidance systems like magnetic tape or laser sensors, while AMRs utilize advanced navigation sensors such as LIDAR, cameras, and SLAM technology for dynamic, autonomous navigation.

LiDAR Mapping

AGVs rely on fixed-path navigation with limited or no LiDAR mapping, while AMRs utilize advanced LiDAR mapping for dynamic environment sensing and autonomous route optimization.

Fixed Route Guidance

Fixed route guidance in AGVs relies on predetermined paths such as magnetic strips or wires, whereas AMRs use dynamic navigation systems with sensors and AI to adapt routes in real-time.

Dynamic Obstacle Avoidance

Autonomous Mobile Robots (AMRs) outperform Automated Guided Vehicles (AGVs) in dynamic obstacle avoidance by utilizing advanced sensors and AI-driven navigation to adapt in real-time to changing environments.

Intralogistics Optimization

AMRs enhance intralogistics optimization by offering dynamic route planning and autonomous decision-making, outperforming traditional AGVs limited to fixed-path navigation.

Payload Capacity

Autonomous Mobile Robots (AMRs) typically offer more flexible and higher payload capacities ranging from 100 kg to over 1,000 kg compared to Automated Guided Vehicles (AGVs), which often have fixed, lower payload limits typically between 200 kg and 1,200 kg.

AGV vs AMR Infographic

njnir.com

njnir.com