Rapid prototyping accelerates the creation of physical models from digital designs, enabling quick evaluation and iteration of product concepts. Rapid tooling, on the other hand, focuses on producing molds or tooling components swiftly to facilitate short-run manufacturing and testing of final parts. While rapid prototyping prioritizes design validation and concept testing, rapid tooling bridges the gap between prototype development and mass production by providing functional tools.

Table of Comparison

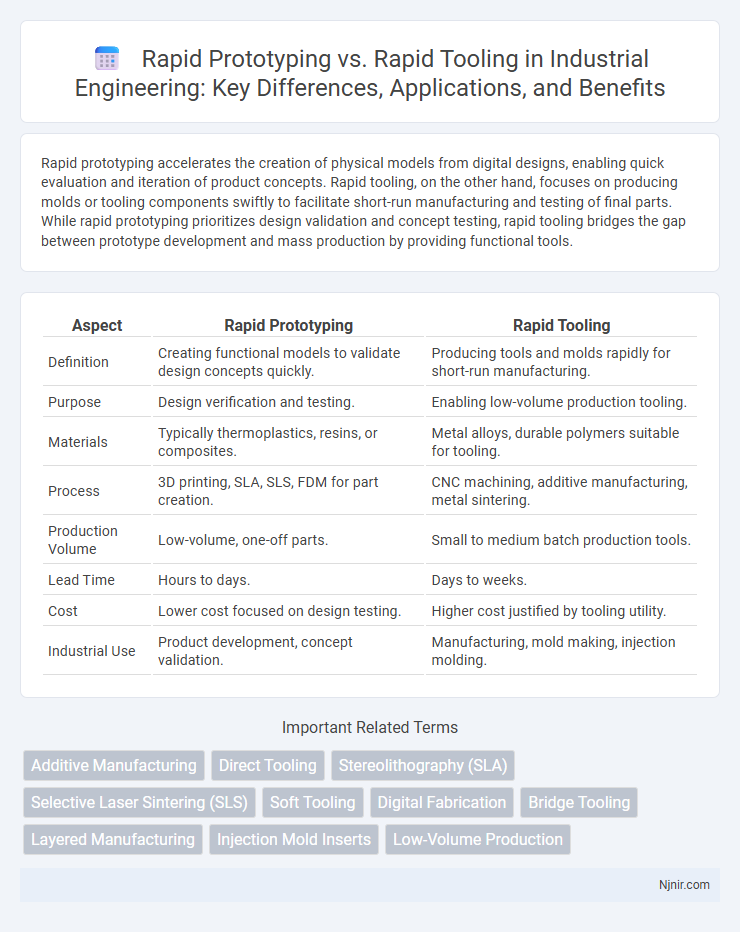

| Aspect | Rapid Prototyping | Rapid Tooling |

|---|---|---|

| Definition | Creating functional models to validate design concepts quickly. | Producing tools and molds rapidly for short-run manufacturing. |

| Purpose | Design verification and testing. | Enabling low-volume production tooling. |

| Materials | Typically thermoplastics, resins, or composites. | Metal alloys, durable polymers suitable for tooling. |

| Process | 3D printing, SLA, SLS, FDM for part creation. | CNC machining, additive manufacturing, metal sintering. |

| Production Volume | Low-volume, one-off parts. | Small to medium batch production tools. |

| Lead Time | Hours to days. | Days to weeks. |

| Cost | Lower cost focused on design testing. | Higher cost justified by tooling utility. |

| Industrial Use | Product development, concept validation. | Manufacturing, mold making, injection molding. |

Introduction to Rapid Prototyping and Rapid Tooling

Rapid prototyping refers to the fast fabrication of a scale model or functional part using 3D printing or additive manufacturing techniques to test form, fit, and function before mass production. Rapid tooling involves creating molds, dies, or tooling components quickly using similar technologies to produce short-run or initial production parts for validation and manufacturing process optimization. Both processes accelerate product development cycles by reducing traditional lead times and enabling early-stage design verification.

Core Principles of Rapid Prototyping

Rapid prototyping centers on quickly creating physical models or parts using additive manufacturing techniques like 3D printing, enabling fast design validation and iterative development. Core principles include speed, accuracy, and flexibility to produce functional prototypes that mimic final product geometry and material properties for testing purposes. Unlike rapid tooling, which focuses on producing molds or tools for mass production, rapid prototyping prioritizes design exploration and refinement.

Fundamentals of Rapid Tooling in Industrial Engineering

Rapid tooling in industrial engineering involves creating tools and molds quickly using additive manufacturing or hybrid processes to accelerate production cycles and reduce costs. This method complements rapid prototyping by focusing on producing functional tools for manufacturing rather than just design validation models. Key fundamentals include material selection, tool durability, and integration with CNC machining to ensure high-quality, precise components for mass production.

Key Technology Differences: Prototyping vs Tooling

Rapid prototyping primarily utilizes additive manufacturing techniques such as 3D printing to quickly create functional or visual models, focusing on speed and design iteration efficiency. In contrast, rapid tooling involves fabricating molds or dies using methods like CNC machining or direct metal laser sintering, emphasizing durability and precision for mass production. The key technological difference lies in prototyping's emphasis on form and functionality testing, while tooling is centered on producing high-quality, repeatable manufacturing tools.

Material Selection for Prototyping and Tooling

Material selection for rapid prototyping typically emphasizes cost-effectiveness, ease of machining, and realistic representation of final product properties, using materials like PLA, ABS, and photopolymer resins. In contrast, rapid tooling requires durable, heat-resistant materials such as aluminum alloys, tool steels, or specialized composites to withstand manufacturing stresses and ensure tool longevity. Optimizing material choice directly impacts the accuracy, functionality, and production efficiency in both prototyping and tooling processes.

Advantages of Rapid Prototyping in Product Development

Rapid prototyping accelerates product development by enabling quick visualization and testing of design concepts, reducing time-to-market and costs associated with traditional methods. It allows for early detection of design flaws and iterative improvements, enhancing product functionality and customer satisfaction. The flexibility of rapid prototyping supports diverse materials and complex geometries, facilitating innovation and effective communication among development teams.

Benefits of Rapid Tooling in Manufacturing Processes

Rapid tooling significantly reduces production lead times by enabling faster creation of molds and components essential for manufacturing processes. It enhances cost-efficiency by minimizing material waste and labor expenses compared to traditional tooling methods. The precision and flexibility offered by rapid tooling improve product quality and allow for quick design modifications, accelerating overall time-to-market.

Limitations and Challenges: Prototyping vs Tooling

Rapid prototyping faces limitations in material properties, scalability, and durability, making prototypes less representative of final products compared to rapid tooling, which struggles with high initial costs, complex tool design, and longer lead times for production tools. Prototyping challenges include accuracy and functional testing constraints, while tooling challenges involve precision in mold fabrication and wear resistance under mass production conditions. The divergence in application goals also dictates distinct limitations, where prototyping emphasizes speed over functionality and tooling focuses on replicability and longevity.

Industry Applications: Choosing the Right Approach

Rapid prototyping accelerates product design validation through quick, low-cost models, ideal for early-stage development in automotive, aerospace, and consumer electronics industries. Rapid tooling, on the other hand, produces functional molds and tools for small-batch manufacturing, crucial in sectors like medical devices and injection molding where precision and short lead times are vital. Selecting between approaches depends on project goals: prototyping suits concept testing, while tooling supports efficient production and end-use part fabrication.

Future Trends in Rapid Manufacturing Technologies

Rapid prototyping is evolving towards integrating multi-material and high-speed additive manufacturing techniques, enabling faster iteration cycles and complex design validations. Rapid tooling is advancing with hybrid manufacturing processes that combine 3D printing and traditional machining to produce durable, functional molds with reduced lead times and costs. Future trends in rapid manufacturing technologies emphasize automation, AI-driven design optimization, and the use of advanced materials like high-performance polymers and metal alloys to enhance production efficiency and product customization.

Additive Manufacturing

Rapid prototyping uses additive manufacturing to quickly create functional models for design evaluation, while rapid tooling employs additive manufacturing to produce molds and tools for efficient low-volume production.

Direct Tooling

Rapid tooling, especially direct tooling, accelerates manufacturing by creating molds or tools directly from CAD data, enabling faster production cycles compared to rapid prototyping, which focuses on producing functional or conceptual prototypes.

Stereolithography (SLA)

Rapid prototyping using Stereolithography (SLA) enables fast, high-detail model creation for design validation, while rapid tooling with SLA produces durable molds or functional parts for limited production runs.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) enables rapid prototyping by quickly producing complex, functional prototypes from powdered materials, while in rapid tooling, SLS creates durable molds that accelerate manufacturing processes and reduce lead times.

Soft Tooling

Soft tooling in rapid prototyping enables faster, cost-effective production of low-volume parts using flexible materials, contrasting with rapid tooling which often targets durable molds for higher-volume manufacturing.

Digital Fabrication

Rapid prototyping in digital fabrication swiftly creates functional models for design validation, while rapid tooling focuses on producing durable molds and tools for efficient mass production.

Bridge Tooling

Bridge tooling rapidly produces functional prototypes using intermediate materials to test form and fit before final mass production tooling is created.

Layered Manufacturing

Layered manufacturing enables rapid prototyping by quickly creating physical models layer-by-layer for design validation, while rapid tooling uses similar layered techniques to produce molds or dies that facilitate mass production.

Injection Mold Inserts

Rapid prototyping uses 3D-printed injection mold inserts for quick design validation, while rapid tooling produces durable, functional mold inserts for short-run injection molding production.

Low-Volume Production

Rapid tooling enables cost-effective low-volume production by creating durable molds, whereas rapid prototyping primarily produces functional models for design validation without tooling durability.

Rapid prototyping vs Rapid tooling Infographic

njnir.com

njnir.com