Additive layering builds components by successively depositing material, enabling complex geometries with minimal waste, while subtractive milling removes material from a solid block, often resulting in higher material loss but higher precision in finished parts. Additive manufacturing excels in rapid prototyping and customization, whereas subtractive milling suits large-scale production requiring tight tolerances. Understanding the trade-offs between material efficiency, design flexibility, and production speed is crucial for selecting the optimal manufacturing process in industrial engineering applications.

Table of Comparison

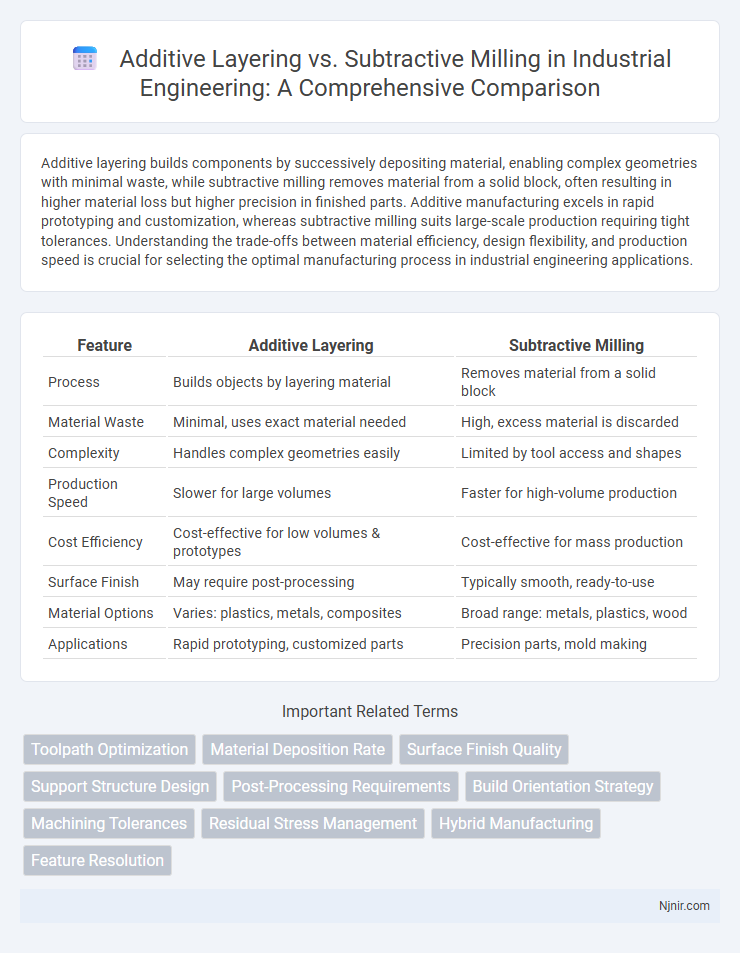

| Feature | Additive Layering | Subtractive Milling |

|---|---|---|

| Process | Builds objects by layering material | Removes material from a solid block |

| Material Waste | Minimal, uses exact material needed | High, excess material is discarded |

| Complexity | Handles complex geometries easily | Limited by tool access and shapes |

| Production Speed | Slower for large volumes | Faster for high-volume production |

| Cost Efficiency | Cost-effective for low volumes & prototypes | Cost-effective for mass production |

| Surface Finish | May require post-processing | Typically smooth, ready-to-use |

| Material Options | Varies: plastics, metals, composites | Broad range: metals, plastics, wood |

| Applications | Rapid prototyping, customized parts | Precision parts, mold making |

Introduction to Additive Layering and Subtractive Milling

Additive layering builds objects by depositing material layer by layer using techniques such as 3D printing, allowing complex geometries and minimal waste. Subtractive milling removes material from a solid block through cutting, drilling, or grinding, offering high precision and smooth finishes. Both processes serve distinct manufacturing needs, with additive layering excelling in prototyping and customization, while subtractive milling is favored for durability and accuracy in final products.

Fundamental Principles of Manufacturing Processes

Additive layering builds objects by successively depositing material, typically through methods like 3D printing, enabling complex geometries with minimal waste. Subtractive milling removes material from a solid block via cutting tools to achieve the desired shape, emphasizing precision and surface finish. Both processes rely on computer-aided design (CAD) models, but additive layering adds material layer-by-layer, while subtractive milling subtracts material to form components.

Material Utilization: Efficiency and Waste Comparison

Additive layering achieves superior material utilization by depositing precise amounts of material, minimizing waste compared to subtractive milling, which removes excess material from a solid block, generating significant scrap. In subtractive milling, up to 70-90% of the original stock can become waste, especially with complex geometries, while additive manufacturing often utilizes close to 90-95% of the material. This efficiency in additive processes leads to cost savings and sustainability benefits by reducing raw material consumption and recycling requirements.

Surface Finish and Dimensional Accuracy

Additive layering typically produces complex geometries with smooth surface finishes, but may require post-processing to achieve high dimensional accuracy due to layer-by-layer deposition variations. Subtractive milling excels in delivering precise dimensional accuracy and superior surface finishes straight off the machine by removing material from a solid block using precise cutting tools. The choice between additive layering and subtractive milling depends on balancing the need for intricate design features against strict tolerances and surface quality demands.

Design Flexibility and Complexity Capabilities

Additive layering offers superior design flexibility by enabling complex geometries and intricate internal structures that are challenging or impossible to achieve with subtractive milling. This process builds parts layer by layer, allowing for lightweight designs and material savings without compromising strength. Subtractive milling, constrained by tool access and cutting paths, often limits complexity but provides high precision for simpler, solid components.

Production Speed and Scalability

Additive layering techniques, such as 3D printing, typically offer faster production speeds for complex and customized parts due to their layer-by-layer material deposition without the need for tooling changes. Subtractive milling excels in scalability for high-volume production, enabling rapid replication of parts once the initial programming and tooling are established, but may have slower turnaround times for prototypes or one-offs. Production speed in additive layering is influenced by build size and resolution, whereas subtractive milling speed depends on material hardness and tool paths.

Energy Consumption and Environmental Impact

Additive layering, also known as 3D printing, generally consumes less energy than subtractive milling, as it builds objects layer by layer using only necessary material, minimizing waste. Subtractive milling requires more energy due to continuous removal of material, which also generates significant waste that must be managed or recycled. Environmentally, additive layering reduces raw material usage and lowers carbon emissions compared to the high energy demands and material waste associated with subtractive manufacturing processes.

Cost Considerations in Industrial Applications

Additive layering offers cost advantages in complex, low-volume industrial applications by reducing material waste and minimizing tooling expenses compared to subtractive milling. Subtractive milling requires significant upfront investment in cutting tools and generates excess material waste, leading to higher costs for intricate designs or small production runs. Industrial sectors prioritize additive layering for prototype development and custom parts to optimize cost efficiency and reduce lead times.

Industry Applications: Case Studies and Use Cases

Additive layering, utilized in industries such as aerospace and biomedical engineering, enables the creation of complex geometries and lightweight components through 3D printing techniques, significantly reducing material waste and production time. Subtractive milling remains dominant in automotive and tooling sectors where precision machining of metal parts from solid blocks ensures high surface finish and tight tolerances critical for mechanical performance. Case studies in the production of custom implants demonstrate additive layering's advantage in patient-specific designs, while subtractive milling is preferred for mass manufacturing of engine components due to scalability and material properties control.

Future Trends in Manufacturing: Integration and Innovation

Additive layering and subtractive milling are converging through hybrid manufacturing systems that combine 3D printing's material efficiency with CNC machining's precision, enabling complex part production with reduced waste. Integration of AI-driven design optimization and real-time process monitoring accelerates innovation, improving customization and scalability in manufacturing. Future trends emphasize the seamless incorporation of additive and subtractive technologies to enhance product performance, reduce lead times, and support sustainable industrial practices.

Toolpath Optimization

Toolpath optimization in additive layering minimizes material waste and build time through precise layer-by-layer deposition, whereas subtractive milling optimizes toolpaths to enhance cutting efficiency and surface finish by strategically removing material from a solid block.

Material Deposition Rate

Additive layering offers a higher material deposition rate compared to subtractive milling, enabling faster production of complex geometries with less material waste.

Surface Finish Quality

Additive layering typically produces rougher surface finishes requiring post-processing, whereas subtractive milling delivers smoother surfaces with higher dimensional accuracy directly from the machining process.

Support Structure Design

Support structure design in additive layering uses minimal, strategically placed supports to reduce material waste and facilitate complex geometries, whereas subtractive milling requires robust fixturing to securely hold the workpiece without additional support structures.

Post-Processing Requirements

Additive layering requires minimal post-processing mainly for surface smoothing, while subtractive milling demands extensive post-processing including deburring, polishing, and dimensional inspection to achieve precise finishes.

Build Orientation Strategy

Build orientation strategy in additive layering optimizes material deposition for complex geometries and minimal support structures, while in subtractive milling it aligns tool paths to enhance surface finish and reduce machining time.

Machining Tolerances

Additive layering typically achieves machining tolerances around +-0.1 mm, while subtractive milling offers higher precision with tolerances as tight as +-0.01 mm, making subtractive milling preferable for applications requiring superior dimensional accuracy.

Residual Stress Management

Additive layering reduces residual stress through controlled layer-by-layer deposition and cooling, whereas subtractive milling often induces higher residual stress due to mechanical cutting forces and thermal gradients.

Hybrid Manufacturing

Hybrid manufacturing combines additive layering and subtractive milling to optimize precision, material efficiency, and production speed in complex part fabrication.

Feature Resolution

Additive layering achieves higher feature resolution by building objects layer-by-layer with precise material deposition, while subtractive milling may have lower resolution due to tool size limitations and material removal constraints.

Additive Layering vs Subtractive Milling Infographic

njnir.com

njnir.com