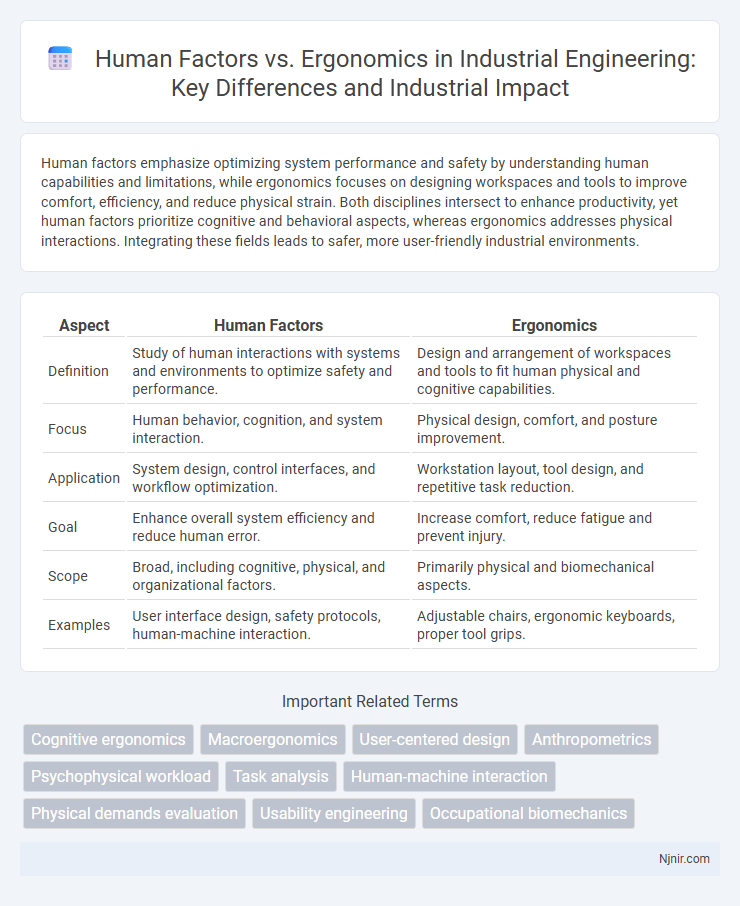

Human factors emphasize optimizing system performance and safety by understanding human capabilities and limitations, while ergonomics focuses on designing workspaces and tools to improve comfort, efficiency, and reduce physical strain. Both disciplines intersect to enhance productivity, yet human factors prioritize cognitive and behavioral aspects, whereas ergonomics addresses physical interactions. Integrating these fields leads to safer, more user-friendly industrial environments.

Table of Comparison

| Aspect | Human Factors | Ergonomics |

|---|---|---|

| Definition | Study of human interactions with systems and environments to optimize safety and performance. | Design and arrangement of workspaces and tools to fit human physical and cognitive capabilities. |

| Focus | Human behavior, cognition, and system interaction. | Physical design, comfort, and posture improvement. |

| Application | System design, control interfaces, and workflow optimization. | Workstation layout, tool design, and repetitive task reduction. |

| Goal | Enhance overall system efficiency and reduce human error. | Increase comfort, reduce fatigue and prevent injury. |

| Scope | Broad, including cognitive, physical, and organizational factors. | Primarily physical and biomechanical aspects. |

| Examples | User interface design, safety protocols, human-machine interaction. | Adjustable chairs, ergonomic keyboards, proper tool grips. |

Introduction to Human Factors and Ergonomics

Human Factors and Ergonomics study the interaction between humans and systems to enhance safety, efficiency, and comfort. Human Factors focuses on cognitive, physical, and psychological aspects affecting human performance, while Ergonomics emphasizes designing workplaces and products that fit human capabilities and limitations. This interdisciplinary field integrates principles from engineering, psychology, and design to optimize human well-being and overall system performance.

Defining Human Factors in Industrial Engineering

Human factors in industrial engineering focus on understanding human capabilities, limitations, and behaviors to optimize system performance and safety. This field integrates psychology, engineering, and design principles to enhance worker efficiency and reduce errors in industrial environments. Ergonomics complements human factors by specifically addressing the design of workstations, tools, and tasks to fit human physical and cognitive abilities.

Understanding Ergonomics: Principles and Scope

Ergonomics focuses on designing systems, products, and environments to optimize human well-being and overall system performance by applying principles such as anthropometry, biomechanics, and cognitive psychology. It encompasses physical, cognitive, and organizational factors to enhance comfort, safety, and productivity across diverse settings like workplaces, healthcare, and consumer products. Human factors is a broader discipline that integrates ergonomics with behavioral sciences to address human capabilities and limitations in complex systems.

Historical Development of Human Factors and Ergonomics

The historical development of Human Factors and Ergonomics (HFE) began during World War II, emphasizing the optimization of soldier-machine interactions to improve safety and performance. Post-war advancements integrated cognitive psychology and engineering, leading to the formalization of ergonomic principles in various industries. The establishment of professional organizations like the Human Factors and Ergonomics Society in 1957 further propelled research, standardization, and application in modern workplaces.

Key Differences Between Human Factors and Ergonomics

Human factors primarily emphasize understanding human capabilities and limitations to optimize system performance, while ergonomics focuses on designing equipment and workspaces that fit the user's physical and cognitive needs. Human factors integrate psychological and physiological principles to improve safety and usability, whereas ergonomics applies practical design solutions to enhance comfort and reduce strain. The key difference lies in human factors addressing broader system interactions, and ergonomics concentrating more specifically on physical interactions between humans and tools or environments.

Overlapping Areas and Collaborative Potential

Human factors and ergonomics share overlapping areas such as designing user-friendly interfaces, optimizing workplace safety, and enhancing human performance through system usability. Both disciplines collaborate to analyze cognitive, physical, and environmental interactions, ensuring products and environments accommodate human capabilities and limitations. This synergy fosters innovative solutions in fields like healthcare, transportation, and manufacturing, improving efficiency and reducing error rates.

Roles in Industrial System Design and Performance

Human factors focus on optimizing operator performance, safety, and comfort by understanding cognitive and physical capabilities within industrial system design. Ergonomics centers on designing tools, workstations, and environments to fit human physical requirements, reducing fatigue and injury risks while improving efficiency. Together, they enhance overall industrial system performance by aligning human capabilities with technological and organizational demands.

Applications in Workplace Safety and Productivity

Human factors and ergonomics both aim to enhance workplace safety and productivity by optimizing interactions between workers and their environment. Human factors focus on understanding cognitive, psychological, and physical capabilities to reduce errors and improve decision-making, while ergonomics emphasizes designing tools, workstations, and systems that fit users' physical needs, reducing strain and injury risks. Implementing human factors and ergonomic principles in industries such as manufacturing and healthcare leads to decreased accident rates, improved employee well-being, and higher operational efficiency.

Emerging Trends in Human Factors and Ergonomics

Emerging trends in human factors and ergonomics emphasize the integration of artificial intelligence and machine learning to enhance user experience and safety across industries. Advances in wearable technology and sensor data analytics enable real-time monitoring of human performance and environmental conditions, driving personalized ergonomic solutions. The shift towards inclusive design standards prioritizes diverse populations, ensuring accessibility and reducing workplace injuries through adaptive and context-aware systems.

Future Directions in Industrial Engineering Integration

Future directions in industrial engineering integration emphasize the convergence of human factors and ergonomics to enhance workplace safety and productivity through advanced sensor technologies and real-time data analytics. Incorporating artificial intelligence and machine learning enables predictive modeling of human-machine interactions, optimizing ergonomic designs and reducing injury risks. Collaborative robots (cobots) and adaptive workstations tailored to individual worker biomechanics represent key innovations driving this integration forward.

Cognitive ergonomics

Cognitive ergonomics examines how human mental processes such as perception, memory, and decision-making interact with system design to improve safety, efficiency, and user experience within human factors and ergonomics.

Macroergonomics

Macroergonomics examines how organizational structures and processes influence human-system interactions, while human factors and ergonomics broadly optimize individual and environmental performance for safety and efficiency.

User-centered design

User-centered design integrates human factors and ergonomics principles to optimize product usability, safety, and user satisfaction by prioritizing users' needs, capabilities, and limitations in the design process.

Anthropometrics

Human factors emphasize optimizing systems for overall human interaction, while ergonomics specifically applies anthropometric data to design tools and environments that fit human body dimensions and improve comfort and performance.

Psychophysical workload

Psychophysical workload in human factors measures individual sensory and cognitive limits affecting performance, while ergonomics designs environments and tools to optimize comfort, safety, and efficiency based on these workload assessments.

Task analysis

Task analysis in human factors evaluates cognitive and physical interactions to enhance system design, while ergonomics applies this data to optimize workplace tools and environments for user comfort and efficiency.

Human-machine interaction

Human factors optimize human capabilities and limitations in designing systems, while ergonomics specifically focuses on physical and cognitive interactions to improve human-machine interaction efficiency and safety.

Physical demands evaluation

Human factors analyze overall system performance including cognitive and physical demands, while ergonomics specifically evaluates physical demands to optimize workstation design and reduce musculoskeletal disorders.

Usability engineering

Usability engineering integrates human factors and ergonomics to optimize interface design, enhancing user performance, satisfaction, and safety in interactive systems.

Occupational biomechanics

Occupational biomechanics examines the physical interactions between workers and their tasks, integrating human factors and ergonomics principles to optimize workplace safety, efficiency, and injury prevention.

Human factors vs Ergonomics Infographic

njnir.com

njnir.com