Demand forecasting involves predicting future customer demand using historical data and statistical models to optimize inventory levels and production schedules. Demand planning incorporates these forecasts to develop actionable strategies that align supply chain operations, procurement, and resource allocation with anticipated market needs. Effective integration of demand forecasting and planning enhances operational efficiency, reduces costs, and improves customer satisfaction in industrial engineering contexts.

Table of Comparison

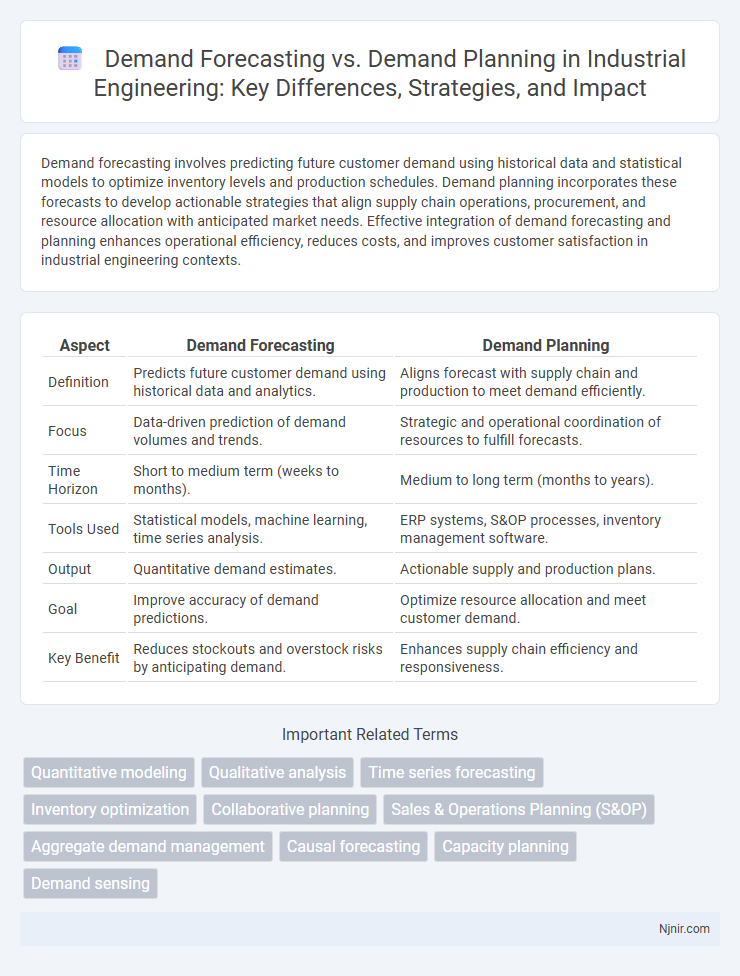

| Aspect | Demand Forecasting | Demand Planning |

|---|---|---|

| Definition | Predicts future customer demand using historical data and analytics. | Aligns forecast with supply chain and production to meet demand efficiently. |

| Focus | Data-driven prediction of demand volumes and trends. | Strategic and operational coordination of resources to fulfill forecasts. |

| Time Horizon | Short to medium term (weeks to months). | Medium to long term (months to years). |

| Tools Used | Statistical models, machine learning, time series analysis. | ERP systems, S&OP processes, inventory management software. |

| Output | Quantitative demand estimates. | Actionable supply and production plans. |

| Goal | Improve accuracy of demand predictions. | Optimize resource allocation and meet customer demand. |

| Key Benefit | Reduces stockouts and overstock risks by anticipating demand. | Enhances supply chain efficiency and responsiveness. |

Understanding Demand Forecasting in Industrial Engineering

Demand forecasting in industrial engineering involves using historical data, statistical models, and machine learning algorithms to predict future product demand with high accuracy. It enables manufacturers to optimize inventory levels, reduce lead times, and improve production scheduling by anticipating market fluctuations. Accurate demand forecasting drives efficient resource allocation, minimizes stockouts and overproduction, and supports strategic decision-making in supply chain management.

The Role of Demand Planning in Modern Industries

Demand planning plays a critical role in modern industries by using historical sales data, market trends, and predictive analytics to create accurate forecasts that drive inventory management and production schedules. Effective demand planning integrates cross-functional collaboration between sales, marketing, and supply chain teams to align supply with customer demand and minimize costs. By anticipating fluctuations and disruptions, demand planning enhances operational efficiency and supports strategic decision-making in dynamic market environments.

Key Differences Between Demand Forecasting and Demand Planning

Demand forecasting involves analyzing historical sales data and market trends to predict future customer demand with statistical models and algorithms. Demand planning encompasses a broader process, integrating demand forecasts with inventory management, supply chain coordination, and sales strategies to create actionable plans that meet business objectives. Key differences include demand forecasting's focus on prediction accuracy, while demand planning emphasizes aligning forecasts with operational capabilities and business goals.

Importance of Accurate Demand Forecasting for Operations

Accurate demand forecasting is critical for optimizing inventory levels, reducing stockouts, and minimizing holding costs within supply chain operations. It provides a data-driven foundation for effective demand planning, enabling companies to align production schedules, procurement, and distribution with anticipated market demand. Enhanced forecast accuracy supports improved customer satisfaction, resource allocation, and operational efficiency, directly impacting profitability and competitive advantage.

Integrating Demand Planning into Industrial Supply Chains

Demand forecasting involves predicting future customer demand using historical data and statistical models, while demand planning integrates these forecasts into broader supply chain strategies to ensure optimal inventory levels and resource allocation. Integrating demand planning into industrial supply chains enhances responsiveness, reduces stockouts, and improves production scheduling by aligning procurement and manufacturing processes with anticipated market needs. Advanced demand planning systems leverage real-time data analytics and collaboration across departments to create a synchronized supply chain that boosts operational efficiency and minimizes costs.

Tools and Techniques for Effective Demand Forecasting

Demand forecasting relies on statistical models, machine learning algorithms, and time series analysis to predict future customer demand with precision. Demand planning integrates these forecasts with inventory management, supply chain coordination, and sales strategies to align production and distribution. Popular tools like SAP Integrated Business Planning, Oracle Demantra, and Microsoft Power BI enable data-driven insights by combining historical sales data, market trends, and real-time analytics for effective demand forecasting.

Collaboration and Data Sharing in Demand Planning

Demand planning relies heavily on collaboration and data sharing between cross-functional teams, including sales, marketing, supply chain, and finance, to create accurate and actionable forecasts. Effective demand planning integrates real-time data from various sources, enabling teams to adjust plans dynamically and align inventory levels with market demand. Enhanced collaboration in demand planning minimizes forecast errors, reduces stockouts, and optimizes resource allocation across the supply chain.

Challenges and Limitations of Demand Forecasting

Demand forecasting faces challenges such as data quality issues, market volatility, and limited ability to predict sudden changes in consumer behavior, which impact accuracy. Limitations include reliance on historical data that may not reflect future trends and difficulties in incorporating external factors like economic shifts or competitor actions. These constraints often necessitate demand planning to integrate forecasting insights with strategic decision-making for more resilient supply chain management.

Best Practices for Aligning Demand Forecasting with Demand Planning

Accurate demand forecasting relies on integrating historical sales data, market trends, and customer insights to generate precise predictions, which sets the foundation for effective demand planning processes. Best practices for aligning demand forecasting with demand planning include implementing collaborative cross-functional teams, utilizing advanced analytics tools, and continuously monitoring forecast accuracy to adjust plans dynamically. Synchronizing these elements enhances inventory management, optimizes supply chain efficiency, and minimizes stockouts and excess inventory.

Future Trends in Demand Forecasting and Planning in Industry

Demand forecasting and demand planning are evolving with advancements in artificial intelligence and machine learning, enabling more accurate predictions based on real-time data and complex algorithms. Industry 4.0 integration and IoT devices facilitate dynamic demand planning by continuously monitoring supply chain variables and market fluctuations. Future trends emphasize increased automation, predictive analytics, and collaboration platforms, improving responsiveness and reducing inventory risks across manufacturing and retail sectors.

Quantitative modeling

Demand forecasting relies on quantitative modeling techniques such as time series analysis, regression, and machine learning to predict future customer demand, while demand planning integrates these forecasts with inventory management and supply chain strategies to align production and distribution.

Qualitative analysis

Demand forecasting utilizes qualitative analysis techniques such as expert judgment and market research to predict future demand patterns, while demand planning integrates these insights into strategic inventory and supply chain decisions.

Time series forecasting

Demand forecasting uses time series forecasting techniques to predict future customer demand patterns, while demand planning integrates these forecasts into inventory and supply chain decisions for optimized resource allocation.

Inventory optimization

Demand forecasting uses historical sales data and predictive analytics to estimate future customer demand, while demand planning integrates these forecasts with inventory optimization strategies to balance stock levels, reduce carrying costs, and prevent stockouts.

Collaborative planning

Collaborative planning enhances demand forecasting and demand planning by integrating cross-functional teams and real-time data to improve accuracy and alignment in supply chain decisions.

Sales & Operations Planning (S&OP)

Demand forecasting predicts future customer demand using historical sales data, while demand planning integrates these forecasts within Sales & Operations Planning (S&OP) to align production, inventory, and sales strategies for optimized supply chain management.

Aggregate demand management

Aggregate demand management integrates demand forecasting to predict overall market needs while demand planning allocates resources to meet those projected demands efficiently.

Causal forecasting

Causal forecasting in demand forecasting uses external variables like economic indicators or marketing campaigns to predict future demand, while demand planning integrates these forecasts with inventory and supply chain strategies to ensure product availability.

Capacity planning

Demand forecasting predicts future customer demand using historical data and market trends, while demand planning integrates these forecasts with capacity planning to align production resources and optimize supply chain efficiency.

Demand sensing

Demand sensing leverages real-time data and advanced analytics to improve demand forecasting accuracy by quickly detecting short-term market changes and customer behavior shifts, bridging the gap between demand forecasting and demand planning.

Demand forecasting vs Demand planning Infographic

njnir.com

njnir.com