Work Sampling provides a statistical estimate of how time is distributed among different activities by observing random samples, making it ideal for analyzing varied and infrequent tasks with less disruption. Time Study offers precise measurements of task durations by continuously timing specific work elements, suitable for repetitive processes requiring detailed performance standards. Selecting between Work Sampling and Time Study depends on the nature of the workflow, accuracy requirements, and available observation resources.

Table of Comparison

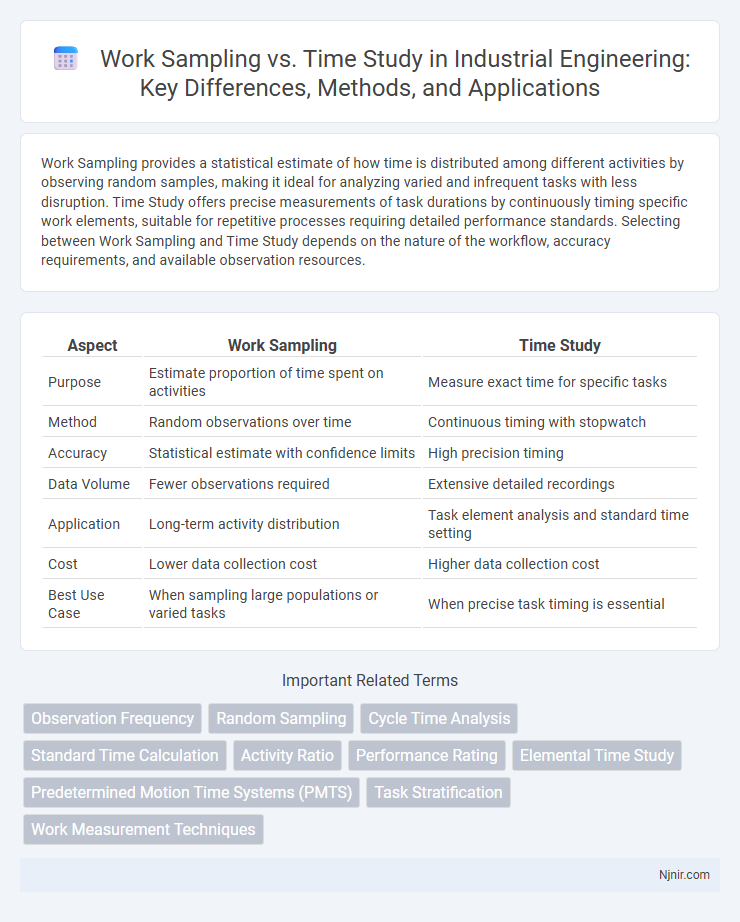

| Aspect | Work Sampling | Time Study |

|---|---|---|

| Purpose | Estimate proportion of time spent on activities | Measure exact time for specific tasks |

| Method | Random observations over time | Continuous timing with stopwatch |

| Accuracy | Statistical estimate with confidence limits | High precision timing |

| Data Volume | Fewer observations required | Extensive detailed recordings |

| Application | Long-term activity distribution | Task element analysis and standard time setting |

| Cost | Lower data collection cost | Higher data collection cost |

| Best Use Case | When sampling large populations or varied tasks | When precise task timing is essential |

Introduction to Work Sampling and Time Study

Work Sampling is a statistical technique used to estimate the proportion of time spent on various activities by observing random samples, making it ideal for analyzing tasks with irregular cycles. Time Study involves continuous timing and detailed observation of work processes to establish standard times for specific tasks, focusing on precise measurement and motion analysis. Both methods aim to improve productivity but differ in data collection approach, with Work Sampling providing probabilistic insights and Time Study delivering exact time measurements.

Key Differences Between Work Sampling and Time Study

Work sampling involves observing random samples of work at intervals to estimate the proportion of time spent on various activities, making it suitable for jobs with irregular tasks. Time study requires continuous timing of a worker's tasks to establish standard times, ideal for repetitive and standardized processes. Work sampling reduces observation time and cost but offers less precision compared to the detailed and exact measurements obtained through time study.

Principles and Objectives of Work Sampling

Work Sampling is based on statistical principles that involve observing random samples of work activities to estimate the proportion of time spent on various tasks, aiming to improve labor efficiency without continuous monitoring. Its objective is to analyze work patterns and workforce utilization by collecting representative data points that reflect actual work behavior over time. Unlike Time Study, which requires continuous timing of tasks, Work Sampling provides a cost-effective method to identify bottlenecks and optimize workflow through probabilistic analysis.

Fundamentals and Techniques of Time Study

Work Sampling provides probabilistic estimates of work activities by observing at random intervals, suitable for long-term analysis and diverse tasks, while Time Study precisely measures task durations through continuous timing to establish standard times. Time Study fundamentals involve selecting tasks, breaking them into elements, timing with a stopwatch, and applying rating factors to adjust observed times for worker pace. Techniques include continuous timing for repetitive tasks, snapback timing for variable tasks, and methods-time measurement (MTM) integration for detailed motion analysis.

Advantages of Work Sampling in Industrial Engineering

Work sampling offers significant advantages in industrial engineering by providing a cost-effective and less intrusive method for analyzing work processes compared to time studies. It enables engineers to gather representative data over extended periods without continuous observation, leading to more accurate assessments of worker utilization and machine efficiency. This approach is particularly beneficial in environments with high variability or intermittent work, improving decision-making and resource allocation.

Benefits and Limitations of Time Study

Time study offers precise measurement of task durations by breaking work into elemental steps, enabling detailed productivity analysis and standardized work procedures. Benefits include improved process efficiency, accurate labor cost estimation, and identification of bottlenecks, which facilitate better workforce planning. Limitations involve the time-intensive data collection, potential worker fatigue or altered performance due to observation, and reduced applicability in variable or non-repetitive work environments.

Applications of Work Sampling in Industry

Work sampling is widely applied in industries for measuring labor productivity, estimating machine utilization, and identifying bottlenecks in production processes. It enables managers to gather representative data on work patterns and idle times without continuous observation, facilitating cost-effective analysis of workforce efficiency across diverse sectors like manufacturing, healthcare, and logistics. This technique supports resource allocation and process improvement decisions by providing statistically reliable insights into operational performance.

Situations Ideal for Using Time Study

Time study is ideal for situations requiring precise measurement of task durations in repetitive, short-cycle operations, such as assembly line work or machining processes. It provides detailed data on individual elements of work, enabling accurate labor time standards and productivity analysis. This method is best suited for controlled environments where tasks are consistent and highly standardized.

Factors Influencing the Choice Between Work Sampling and Time Study

The choice between work sampling and time study depends on factors such as the nature of the task, required accuracy, and available resources. Work sampling suits jobs with irregular activities and large sample sizes, offering cost-effective data collection with less precision. Time study is preferred for repetitive tasks requiring high accuracy and detailed time measurements, despite being more time-consuming and resource-intensive.

Future Trends in Work Measurement Techniques

Future trends in work measurement emphasize increased adoption of artificial intelligence and machine learning to enhance accuracy in both work sampling and time study methodologies. Integration of real-time data analytics and wearable technology enables more dynamic and continuous monitoring of worker productivity and task timings. Automation and digital platforms are expected to streamline data collection, reducing human error and providing actionable insights for optimized workforce management.

Observation Frequency

Work sampling involves random, infrequent observations to estimate activity proportions, while time study uses continuous, frequent observations to measure task durations precisely.

Random Sampling

Random sampling in work sampling provides statistically reliable estimates of work distribution by observing activities at random intervals, contrasting with time study's continuous measurement of task durations.

Cycle Time Analysis

Work Sampling estimates cycle time by analyzing random observations of task performance, while Time Study measures cycle time through continuous timing of individual work elements for precise cycle time analysis.

Standard Time Calculation

Work sampling estimates standard time by analyzing random observations of work activities, while time study calculates standard time through continuous timing of tasks and detailed motion analysis.

Activity Ratio

Work sampling estimates activity ratio by analyzing random observations over time while time study calculates it through continuous task timing for precise productivity measurement.

Performance Rating

Work sampling estimates performance through random observations, while time study relies on continuous measurement adjusted by performance rating factors to assess worker efficiency accurately.

Elemental Time Study

Elemental Time Study provides precise measurement of individual task elements, enhancing accuracy over Work Sampling by capturing detailed time data for optimized workflow analysis.

Predetermined Motion Time Systems (PMTS)

Predetermined Motion Time Systems (PMTS) provide precise task time standards by analyzing elemental motions, contrasting with Work Sampling's probabilistic activity observations and Time Study's direct timing of tasks.

Task Stratification

Work sampling uses random observations to estimate task stratification percentages, while time study involves continuous timing to accurately measure task durations for detailed stratification analysis.

Work Measurement Techniques

Work sampling provides statistically reliable estimates of work distribution through random observations, while time study precisely measures task durations using continuous timing, both essential work measurement techniques for optimizing labor productivity.

Work Sampling vs Time Study Infographic

njnir.com

njnir.com