Flexible automation offers versatile production capabilities by allowing easy reprogramming and adaptation to different tasks, enhancing efficiency in dynamic manufacturing environments. Fixed automation, characterized by specialized machinery designed for a specific production process, excels in high-volume, repetitive operations with minimal variation. The choice between flexible and fixed automation depends on production volume, product variety, and the need for adaptability in industrial engineering applications.

Table of Comparison

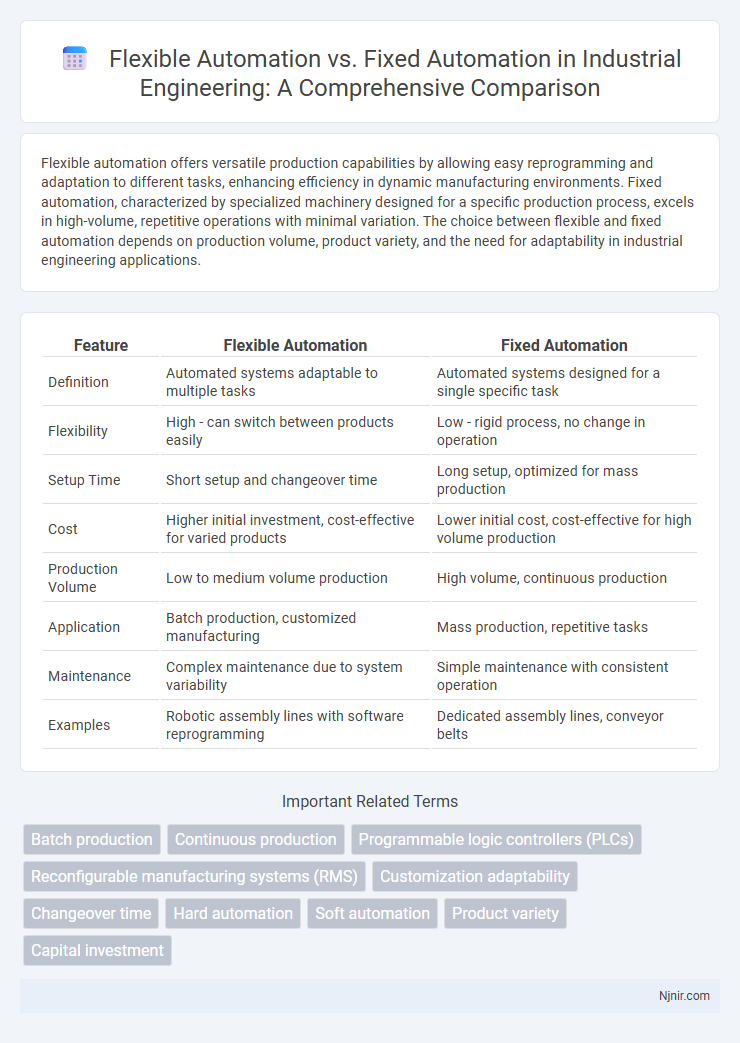

| Feature | Flexible Automation | Fixed Automation |

|---|---|---|

| Definition | Automated systems adaptable to multiple tasks | Automated systems designed for a single specific task |

| Flexibility | High - can switch between products easily | Low - rigid process, no change in operation |

| Setup Time | Short setup and changeover time | Long setup, optimized for mass production |

| Cost | Higher initial investment, cost-effective for varied products | Lower initial cost, cost-effective for high volume production |

| Production Volume | Low to medium volume production | High volume, continuous production |

| Application | Batch production, customized manufacturing | Mass production, repetitive tasks |

| Maintenance | Complex maintenance due to system variability | Simple maintenance with consistent operation |

| Examples | Robotic assembly lines with software reprogramming | Dedicated assembly lines, conveyor belts |

Introduction to Automation in Industrial Engineering

Flexible automation allows for rapid reprogramming of machines to handle varying product designs, making it ideal for industries with diverse production needs and frequent product changes. Fixed automation uses specialized equipment for high-volume manufacturing of a single product, optimizing speed and efficiency but lacking adaptability. Industrial engineering leverages both automation types to balance cost, flexibility, and throughput in manufacturing processes.

Understanding Fixed Automation: Definition and Applications

Fixed automation, also known as hard automation, involves the use of specialized equipment designed for high-volume production with little to no variation in product design. This type of automation excels in industries such as automotive manufacturing, where the repetitive assembly of identical parts demands consistent precision and speed. Its primary applications include mass production of standardized items like car engines, electronic circuit boards, and household appliances, offering optimal efficiency but limited flexibility for product changes.

Defining Flexible Automation and Its Benefits

Flexible automation refers to a production system designed to easily adapt to changes in product types and volumes without extensive reconfiguration. It offers significant benefits such as reduced downtime, increased efficiency in manufacturing diverse products, and enhanced responsiveness to market demands. This automation type supports customization, facilitating quick adjustments that optimize resource utilization and lower operational costs.

Key Differences Between Flexible and Fixed Automation

Flexible automation systems enable quick adaptation to varying product designs and small batch sizes through programmable machines, enhancing versatility and production agility. Fixed automation relies on dedicated equipment designed for high-volume, repetitive tasks, delivering higher efficiency but limited flexibility. The primary difference lies in flexibility versus efficiency, where flexible automation suits dynamic manufacturing environments, and fixed automation excels in stable, high-output processes.

Cost Considerations: Flexible vs Fixed Automation

Flexible automation typically involves higher initial capital investment due to advanced programmable equipment but offers lower long-term costs through adaptability and reduced changeover time. Fixed automation requires substantial upfront costs for dedicated machinery and tooling, with minimal flexibility leading to potentially higher expenses if product design or volume changes occur. Evaluating cost efficiency depends on production volume, product variety, and the need for rapid reconfiguration versus stable, high-volume manufacturing.

Impact on Production Efficiency and Throughput

Flexible automation enhances production efficiency by allowing quick adaptation to product changes without significant downtime, increasing throughput through the ability to handle multiple product variants simultaneously. Fixed automation, while delivering high throughput for standardized tasks due to its specialized design, lacks adaptability, leading to reduced efficiency during product changeovers or demand fluctuations. The choice between the two impacts production scalability and responsiveness, with flexible systems supporting dynamic manufacturing environments and fixed automation excelling in high-volume, repetitive processes.

Scalability and Adaptability in Manufacturing Systems

Flexible automation excels in scalability and adaptability by allowing manufacturers to quickly reprogram or reconfigure equipment for different products, accommodating varying production volumes without extensive downtime. Fixed automation, while highly efficient for high-volume, repetitive tasks, lacks the flexibility to adapt to product changes, making it less scalable for diverse manufacturing needs. The ability of flexible automation systems to integrate advanced robotics and AI-driven controls enhances responsiveness to market demand shifts and customization trends.

Technology Requirements for Flexible and Fixed Automation

Flexible automation demands advanced programmable controllers and sophisticated robotics capable of quick changeovers to accommodate varying product designs. Fixed automation requires specialized machinery with dedicated control systems optimized for high-volume, repetitive tasks with minimal variation. Both systems rely on sensors and actuators, but flexible automation integrates more complex software for adaptability, whereas fixed automation emphasizes durability and precision in a consistent production environment.

Industry Use Cases: When to Choose Flexible or Fixed Automation

Flexible automation excels in industries requiring frequent product changes and customization, such as automotive prototyping and electronics manufacturing, where adaptability reduces downtime and meets diverse demands. Fixed automation suits high-volume, repetitive tasks like automotive assembly lines or bottling plants, offering higher speed, precision, and lower unit costs. Choosing between flexible and fixed automation depends on production volume, product variety, and cost-efficiency priorities in sectors like consumer goods, aerospace, and pharmaceuticals.

Future Trends in Industrial Automation

Future trends in industrial automation emphasize the growing shift towards flexible automation systems capable of rapid reconfiguration and adaptation to varied product lines, driven by advancements in AI, machine learning, and robotics. Fixed automation, while still valuable for high-volume, repetitive tasks, is increasingly supplemented or replaced by modular, software-driven platforms that enable real-time customization and scalability. Emerging technologies such as digital twins and IoT integration are enhancing flexible automation's efficiency and predictive maintenance, positioning it as the dominant approach for Industry 4.0 and smart manufacturing environments.

Batch production

Flexible automation enhances batch production by quickly adapting machinery for varied products, while fixed automation is suited for high-volume, repetitive batch processes with minimal changeover.

Continuous production

Flexible automation enhances continuous production by allowing quick adjustments to different products, whereas fixed automation maximizes efficiency for high-volume, uniform output with minimal variation.

Programmable logic controllers (PLCs)

Programmable logic controllers (PLCs) enable flexible automation by allowing easy reprogramming for varied tasks, unlike fixed automation which relies on hardwired, unchangeable systems.

Reconfigurable manufacturing systems (RMS)

Reconfigurable manufacturing systems (RMS) offer superior adaptability compared to fixed automation by enabling rapid reconfiguration of equipment and processes to accommodate product variety and changing production volumes, bridging the gap between rigid fixed automation and highly flexible automation.

Customization adaptability

Flexible automation offers higher customization adaptability by enabling rapid changes to production processes, while fixed automation provides limited adaptability with predefined, rigid setups.

Changeover time

Flexible automation significantly reduces changeover time by enabling quick adaptations between different tasks, whereas fixed automation involves longer, costly changeovers due to its rigid, specialized setup.

Hard automation

Hard automation in fixed automation systems uses specialized equipment designed for high-volume, repetitive tasks, offering efficiency but limited flexibility compared to flexible automation.

Soft automation

Soft automation enhances flexible automation by integrating programmable controls and adaptable machinery that quickly switch tasks, unlike fixed automation which relies on rigid, specialized equipment for high-volume production.

Product variety

Flexible automation efficiently handles high product variety with quick changeovers, while fixed automation is optimized for low product variety with high volume production.

Capital investment

Flexible automation requires lower capital investment than fixed automation due to its adaptability for multiple product types.

Flexible automation vs Fixed automation Infographic

njnir.com

njnir.com