FMEA (Failure Modes and Effects Analysis) systematically identifies potential failure modes and their impacts on industrial processes, enabling proactive risk mitigation. FMECA (Failure Modes, Effects, and Criticality Analysis) extends FMEA by incorporating a criticality assessment that quantifies the severity and likelihood of each failure, prioritizing failure modes for corrective actions. This integration of risk prioritization in FMECA allows industrial engineers to allocate resources more effectively and enhance process reliability.

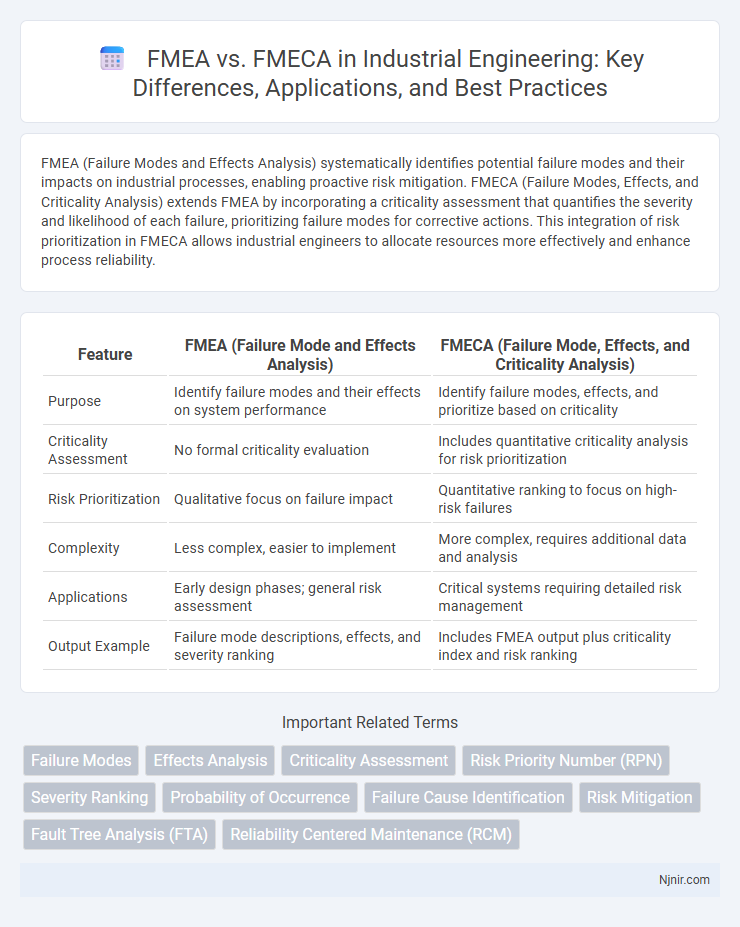

Table of Comparison

| Feature | FMEA (Failure Mode and Effects Analysis) | FMECA (Failure Mode, Effects, and Criticality Analysis) |

|---|---|---|

| Purpose | Identify failure modes and their effects on system performance | Identify failure modes, effects, and prioritize based on criticality |

| Criticality Assessment | No formal criticality evaluation | Includes quantitative criticality analysis for risk prioritization |

| Risk Prioritization | Qualitative focus on failure impact | Quantitative ranking to focus on high-risk failures |

| Complexity | Less complex, easier to implement | More complex, requires additional data and analysis |

| Applications | Early design phases; general risk assessment | Critical systems requiring detailed risk management |

| Output Example | Failure mode descriptions, effects, and severity ranking | Includes FMEA output plus criticality index and risk ranking |

Introduction to FMEA and FMECA

FMEA (Failure Mode and Effects Analysis) is a systematic method used to identify potential failure modes in a product or process and assess their impact on system performance. FMECA (Failure Mode, Effects, and Criticality Analysis) builds on FMEA by incorporating a criticality assessment to prioritize failures based on severity and occurrence probability. Both techniques enhance reliability and risk management during design and operational phases.

Definitions: FMEA vs FMECA

FMEA (Failure Modes and Effects Analysis) systematically identifies potential failure modes within a system and assesses their impact on system performance. FMECA (Failure Modes, Effects, and Criticality Analysis) extends FMEA by incorporating a criticality assessment, prioritizing failure modes based on severity, occurrence, and detectability to guide risk management efforts. The primary difference lies in FMECA's additional focus on quantifying risk, enabling focused mitigation strategies for the most critical failure modes.

Historical Development and Evolution

FMEA (Failure Modes and Effects Analysis) originated in the 1940s within the aerospace industry to systematically identify potential failure modes and their effects on system performance. FMECA (Failure Modes, Effects, and Criticality Analysis) evolved from FMEA in the 1960s by integrating a criticality assessment to prioritize failures based on their severity, frequency, and detectability, enhancing risk management strategies. Both methodologies have continuously advanced through industries such as automotive, defense, and healthcare, driven by increasing complexity and regulatory requirements for safety and reliability.

Objectives and Scope of Each Method

FMEA (Failure Modes and Effects Analysis) aims to identify potential failure modes within a system, assessing their effects to enhance reliability and safety, typically focusing on qualitative analysis of risks. FMECA (Failure Modes, Effects, and Criticality Analysis) extends FMEA by quantifying the criticality of each failure mode, incorporating severity, occurrence, and detection ratings to prioritize risk mitigation efforts more precisely. The scope of FMEA covers overall failure identification and preventive measures, whereas FMECA includes a detailed criticality assessment to support decision-making in reliability engineering and maintenance planning.

Key Steps in FMEA Process

The key steps in the FMEA process include identifying failure modes, analyzing potential effects, and assessing severity, occurrence, and detection ratings to calculate risk priority numbers (RPN). This systematic approach enables teams to prioritize risks and develop effective mitigation strategies for product or process reliability. FMECA extends FMEA by incorporating criticality analysis, which quantifies the impact and likelihood of failures to focus resources on the most critical issues.

Key Steps in FMECA Process

FMECA (Failure Modes, Effects, and Criticality Analysis) extends FMEA by incorporating a criticality assessment that prioritizes failure modes based on their severity, occurrence, and detectability. Key steps in the FMECA process include identifying potential failure modes, analyzing their effects, assigning severity ratings, calculating criticality by combining probability and impact, and prioritizing risks for mitigation. This method enables organizations to focus resources on the most critical failure modes to enhance system reliability and safety.

Differences Between FMEA and FMECA

FMEA (Failure Mode and Effects Analysis) identifies potential failure modes and their effects to improve product reliability, while FMECA (Failure Mode, Effects, and Criticality Analysis) extends this by quantitatively assessing the criticality or severity of each failure mode to prioritize risks. FMECA integrates a risk priority number (RPN) or criticality index to rank failure modes based on severity, occurrence, and detectability, unlike FMEA, which typically focuses on qualitative analysis. The criticality assessment in FMECA enables more precise resource allocation for mitigation efforts compared to the broader scope of FMEA.

Advantages and Limitations of FMEA

FMEA (Failure Modes and Effects Analysis) offers a systematic approach to identify potential failure modes and their causes, enabling proactive risk mitigation and improving product reliability. Its advantages include simplicity, cost-effectiveness, and ease of implementation across various industries. Limitations of FMEA involve its qualitative nature, potential subjectivity in risk prioritization, and insufficient emphasis on criticality assessment without integrating FMECA (Failure Modes, Effects, and Criticality Analysis).

Advantages and Limitations of FMECA

FMECA (Failure Modes, Effects, and Criticality Analysis) extends FMEA by incorporating a criticality assessment that quantifies the severity and probability of failures, enabling prioritization of risks based on their impact on system reliability and safety. Advantages of FMECA include enhanced decision-making support through risk ranking, improved allocation of resources to address the most critical failure modes, and better compliance with safety standards in aerospace, automotive, and defense industries. Limitations involve increased complexity and time requirements compared to FMEA, potential subjectivity in criticality scoring, and the need for detailed data, which may not be readily available in early design phases.

Best Practices for Implementing FMEA and FMECA in Industry

Effective implementation of FMEA and FMECA in industry requires cross-functional team collaboration to thoroughly identify potential failure modes and assess their effects on system reliability. Utilizing risk priority numbers (RPN) or criticality analysis ensures prioritization of the most significant risks, guiding mitigation efforts efficiently. Continuous documentation updates and feedback loops facilitate dynamic risk management, enhancing product quality and safety throughout the lifecycle.

Failure Modes

FMEA identifies and analyzes potential failure modes and their effects, while FMECA extends this by also assessing the criticality to prioritize risks effectively.

Effects Analysis

FMECA extends FMEA by incorporating criticality analysis to prioritize failure effects based on their severity and likelihood, enhancing risk assessment accuracy.

Criticality Assessment

FMECA enhances FMEA by integrating Criticality Assessment, quantifying risk to prioritize failure modes based on severity, occurrence, and detectability for more effective risk management.

Risk Priority Number (RPN)

FMECA enhances FMEA by incorporating criticality analysis alongside the Risk Priority Number (RPN) to prioritize failure modes based on severity, occurrence, and detectability.

Severity Ranking

FMECA enhances FMEA by incorporating a Severity Ranking to prioritize potential failure modes based on their impact on system performance and safety.

Probability of Occurrence

FMECA enhances FMEA by incorporating the Probability of Occurrence to prioritize potential failure modes based on their likelihood and severity for effective risk management.

Failure Cause Identification

FMECA enhances FMEA by incorporating criticality analysis to prioritize failure cause identification based on risk severity and likelihood.

Risk Mitigation

FMECA enhances FMEA by quantitatively assessing failure modes with severity, occurrence, and detection ratings to prioritize risk mitigation efforts more effectively.

Fault Tree Analysis (FTA)

FMECA enhances FMEA by incorporating criticality analysis and integrates Fault Tree Analysis (FTA) to systematically identify root causes and failure propagation paths, improving risk prioritization and mitigation strategies.

Reliability Centered Maintenance (RCM)

FMECA enhances FMEA by incorporating criticality analysis, making it essential for Reliability Centered Maintenance (RCM) to prioritize maintenance tasks based on failure impact and likelihood.

FMEA vs FMECA Infographic

njnir.com

njnir.com