Predictive maintenance leverages real-time data and advanced analytics to forecast equipment failures before they occur, optimizing maintenance schedules and reducing unplanned downtime. Condition-based maintenance relies on continuous monitoring of equipment health parameters to trigger maintenance only when specific threshold values are reached. While both strategies aim to enhance asset reliability, predictive maintenance offers a more proactive approach by anticipating issues and enabling timely interventions.

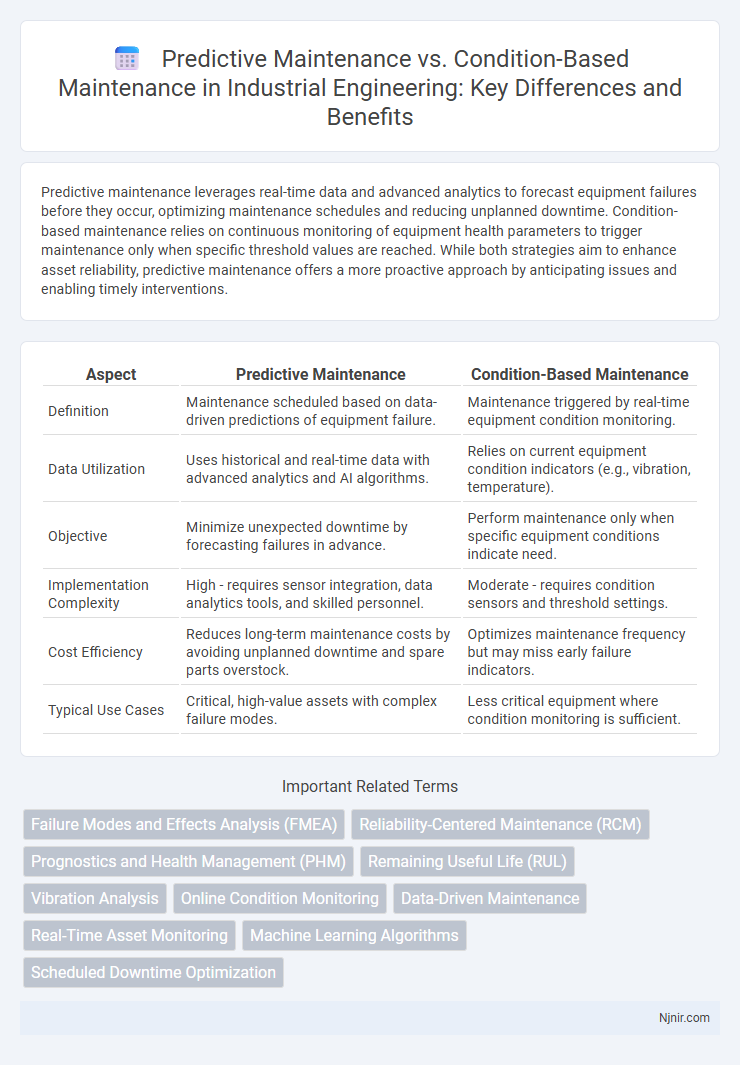

Table of Comparison

| Aspect | Predictive Maintenance | Condition-Based Maintenance |

|---|---|---|

| Definition | Maintenance scheduled based on data-driven predictions of equipment failure. | Maintenance triggered by real-time equipment condition monitoring. |

| Data Utilization | Uses historical and real-time data with advanced analytics and AI algorithms. | Relies on current equipment condition indicators (e.g., vibration, temperature). |

| Objective | Minimize unexpected downtime by forecasting failures in advance. | Perform maintenance only when specific equipment conditions indicate need. |

| Implementation Complexity | High - requires sensor integration, data analytics tools, and skilled personnel. | Moderate - requires condition sensors and threshold settings. |

| Cost Efficiency | Reduces long-term maintenance costs by avoiding unplanned downtime and spare parts overstock. | Optimizes maintenance frequency but may miss early failure indicators. |

| Typical Use Cases | Critical, high-value assets with complex failure modes. | Less critical equipment where condition monitoring is sufficient. |

Introduction to Predictive and Condition-Based Maintenance

Predictive maintenance uses data analysis, machine learning, and real-time monitoring to forecast equipment failures, minimizing downtime and maintenance costs. Condition-based maintenance relies on real-time condition monitoring techniques such as vibration analysis, temperature measurement, and oil analysis to perform maintenance only when specific signs of deterioration appear. Both strategies aim to enhance asset reliability and operational efficiency by shifting from time-based schedules to condition-driven interventions.

Key Principles of Predictive Maintenance

Predictive maintenance relies on real-time data analysis and advanced analytics such as machine learning and IoT sensors to forecast equipment failures before they occur, minimizing unexpected downtime. It emphasizes continuous monitoring and trend analysis of asset conditions, enabling maintenance interventions precisely when needed based on predictive insights. Key principles include data-driven decision making, early fault detection, and optimizing maintenance schedules to enhance asset lifecycle and operational efficiency.

Fundamentals of Condition-Based Maintenance

Condition-Based Maintenance (CBM) relies on real-time data from sensors monitoring equipment health, enabling maintenance activities based on actual machine conditions rather than preset schedules. This method focuses on key parameters such as vibration, temperature, and pressure to detect early signs of wear or failure, reducing downtime and maintenance costs. Unlike Predictive Maintenance, which uses historical data and advanced analytics to forecast failures, CBM directly addresses current operational status to provide timely interventions.

Core Differences Between Predictive and Condition-Based Maintenance

Predictive maintenance leverages advanced data analytics, sensors, and machine learning algorithms to forecast equipment failures before they occur, enabling proactive scheduling of repairs. Condition-based maintenance relies on real-time monitoring of equipment conditions, such as vibration, temperature, or pressure thresholds, to determine when maintenance actions are necessary. The core difference lies in predictive maintenance's focus on anticipation and trend analysis versus condition-based maintenance's reliance on current state and specific condition triggers.

Data Collection Methods in Maintenance Strategies

Predictive maintenance relies on advanced data collection methods such as IoT sensors, real-time monitoring, and machine learning algorithms to analyze equipment performance trends and predict failures before they occur. Condition-based maintenance primarily uses condition monitoring tools like vibration analysis, thermography, and oil analysis to assess the current state of machinery and determine maintenance needs. Both strategies emphasize data accuracy and frequency, but predictive maintenance integrates broader data sources for proactive decision-making, while condition-based maintenance focuses on immediate equipment condition diagnostics.

Advantages of Predictive Maintenance in Industrial Engineering

Predictive maintenance leverages real-time data analytics and machine learning algorithms to anticipate equipment failures before they occur, enabling timely interventions that minimize downtime and optimize resource allocation. This approach enhances operational efficiency by reducing unexpected breakdowns and maintenance costs compared to condition-based maintenance, which relies solely on periodic inspections and threshold-based alerts. Industrial engineering benefits from predictive maintenance through extended asset life, improved safety, and increased production reliability.

Benefits of Condition-Based Maintenance for Industrial Operations

Condition-Based Maintenance (CBM) significantly enhances industrial operations by enabling real-time monitoring and precise detection of equipment health, which minimizes unplanned downtime and extends asset lifespan. CBM leverages advanced sensors and IoT technology to provide accurate data for timely maintenance interventions, reducing unnecessary part replacements and optimizing maintenance costs. This targeted approach increases operational efficiency, improves safety, and delivers higher overall equipment effectiveness (OEE) compared to traditional predictive maintenance methods.

Implementation Challenges and Solutions

Implementation challenges in predictive maintenance include the need for advanced data analytics, high sensor integration costs, and the complexity of developing accurate machine learning models. Condition-based maintenance faces difficulties such as limited real-time data accuracy, sensor degradation, and the challenge of setting precise maintenance thresholds. Solutions involve investing in robust IoT infrastructure, employing adaptive algorithms with continuous model training, and integrating edge computing to improve data reliability and reduce latency.

Cost-Benefit Analysis: Predictive vs. Condition-Based Maintenance

Predictive maintenance leverages real-time data analytics and machine learning algorithms to forecast equipment failures, enabling proactive interventions that reduce downtime and repair costs. Condition-based maintenance relies on specific equipment condition indicators, such as vibration or temperature thresholds, leading to maintenance only when necessary, which can lower unnecessary inspections but may risk unexpected failures. Cost-benefit analysis reveals predictive maintenance often yields higher return on investment by optimizing maintenance schedules and extending asset life, while condition-based maintenance offers a more straightforward, lower-cost approach suitable for less critical assets.

Future Trends in Industrial Maintenance Technologies

Future trends in industrial maintenance technologies emphasize the integration of predictive maintenance with advanced AI algorithms and IoT sensors to enable real-time data analytics and anomaly detection. Condition-based maintenance continues evolving through enhanced machine learning models that improve the accuracy of equipment health assessments and optimize maintenance schedules. The convergence of edge computing and digital twins is set to revolutionize maintenance strategies by providing dynamic, data-driven insights and reducing downtime more effectively than traditional methods.

Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) enhances predictive maintenance by identifying potential failure modes and their effects early, enabling condition-based maintenance to prioritize real-time monitoring and targeted interventions.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) integrates predictive and condition-based maintenance by prioritizing maintenance tasks based on system reliability data and real-time condition monitoring to optimize asset performance and reduce downtime.

Prognostics and Health Management (PHM)

Prognostics and Health Management (PHM) enhances predictive maintenance by using real-time condition data and advanced analytics to forecast equipment failures more accurately than traditional condition-based maintenance.

Remaining Useful Life (RUL)

Predictive maintenance leverages Remaining Useful Life (RUL) models to forecast equipment failure and schedule maintenance proactively, whereas condition-based maintenance relies on real-time sensor data to perform maintenance only when specific indicators show degradation.

Vibration Analysis

Vibration analysis enhances predictive maintenance by continuously monitoring equipment conditions to detect early faults, whereas condition-based maintenance relies on specific threshold triggers for intervention.

Online Condition Monitoring

Online condition monitoring enhances predictive maintenance by continuously analyzing real-time data to forecast equipment failures more accurately than traditional condition-based maintenance methods.

Data-Driven Maintenance

Data-driven maintenance leverages real-time sensor data and advanced analytics to optimize predictive maintenance strategies, surpassing condition-based maintenance by enabling more accurate failure forecasts and minimizing unplanned downtime.

Real-Time Asset Monitoring

Real-time asset monitoring enables predictive maintenance by continuously analyzing sensor data to forecast equipment failures, whereas condition-based maintenance relies on threshold alerts triggered by specific asset conditions.

Machine Learning Algorithms

Machine learning algorithms enhance predictive maintenance by analyzing real-time condition-based data to forecast equipment failures and optimize maintenance schedules.

Scheduled Downtime Optimization

Predictive maintenance leverages real-time data and analytics to optimize scheduled downtime by accurately forecasting equipment failures, whereas condition-based maintenance relies on fixed thresholds that may lead to less efficient downtime scheduling.

predictive maintenance vs condition-based maintenance Infographic

njnir.com

njnir.com