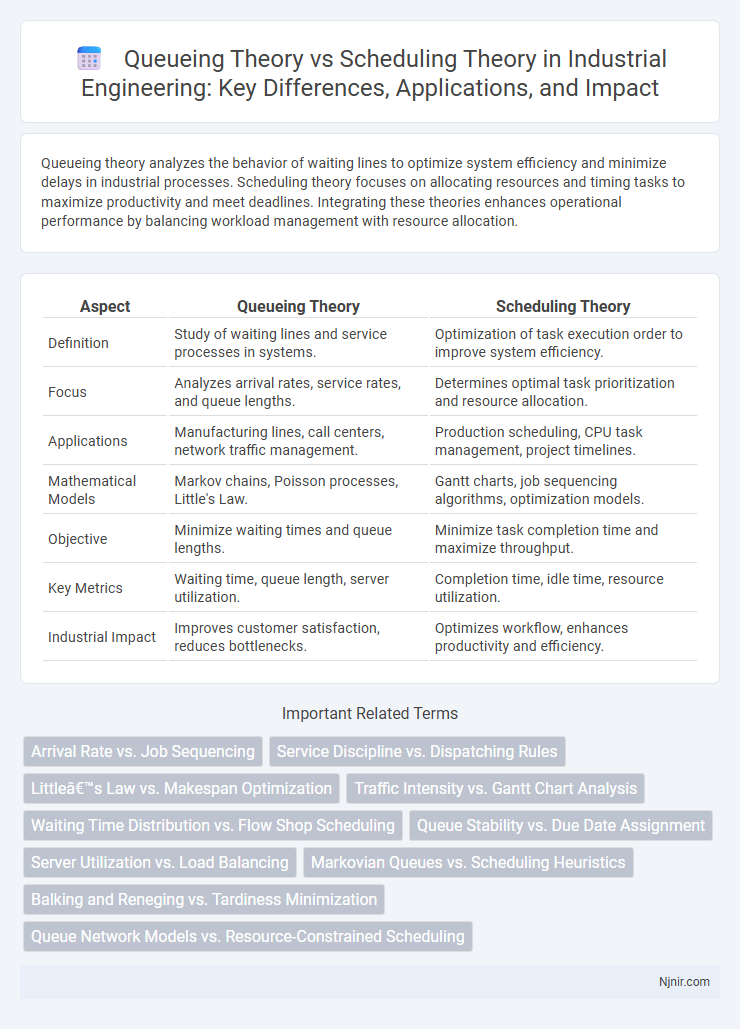

Queueing theory analyzes the behavior of waiting lines to optimize system efficiency and minimize delays in industrial processes. Scheduling theory focuses on allocating resources and timing tasks to maximize productivity and meet deadlines. Integrating these theories enhances operational performance by balancing workload management with resource allocation.

Table of Comparison

| Aspect | Queueing Theory | Scheduling Theory |

|---|---|---|

| Definition | Study of waiting lines and service processes in systems. | Optimization of task execution order to improve system efficiency. |

| Focus | Analyzes arrival rates, service rates, and queue lengths. | Determines optimal task prioritization and resource allocation. |

| Applications | Manufacturing lines, call centers, network traffic management. | Production scheduling, CPU task management, project timelines. |

| Mathematical Models | Markov chains, Poisson processes, Little's Law. | Gantt charts, job sequencing algorithms, optimization models. |

| Objective | Minimize waiting times and queue lengths. | Minimize task completion time and maximize throughput. |

| Key Metrics | Waiting time, queue length, server utilization. | Completion time, idle time, resource utilization. |

| Industrial Impact | Improves customer satisfaction, reduces bottlenecks. | Optimizes workflow, enhances productivity and efficiency. |

Introduction to Queueing Theory and Scheduling Theory

Queueing theory analyzes the behavior of waiting lines, focusing on metrics like arrival rates, service rates, and system capacity to optimize the flow and reduce wait times. Scheduling theory studies the allocation of resources over time to perform a collection of tasks efficiently, emphasizing task prioritization, deadlines, and processing sequences. Both theories are crucial in operations research and computer science for improving system performance and resource utilization.

Fundamental Concepts in Queueing Theory

Queueing theory fundamentally analyzes the behavior of waiting lines, focusing on arrival rates, service rates, and system capacity to optimize resource allocation and minimize wait times. Core models include the M/M/1 and M/G/1 queues, which describe various combinations of Markovian arrival or service processes with single-server queues. Key metrics such as average queue length, waiting time, and system utilization provide essential insights for managing congestion and improving efficiency in service systems.

Core Principles of Scheduling Theory

Scheduling theory centers on allocating limited resources to tasks over time to optimize objectives such as minimizing completion time, maximizing resource utilization, or adhering to deadlines. Core principles include task prioritization based on deadlines or importance, managing resource constraints to avoid conflicts, and sequencing to reduce overall processing time and idle periods. It contrasts with queueing theory, which primarily analyzes stochastic arrival and service processes to predict system performance metrics like wait times and queue lengths.

Key Differences Between Queueing and Scheduling Theories

Queueing theory analyzes the behavior and performance of waiting lines by modeling arrival rates, service rates, and system capacity to minimize wait times and optimize throughput. Scheduling theory focuses on allocating resources or tasks over time, prioritizing task order and resource utilization to enhance efficiency and meet deadlines. While queueing theory emphasizes stochastic processes and system dynamics, scheduling theory centers on deterministic or heuristic algorithms for task sequencing and optimal resource management.

Applications of Queueing Theory in Industrial Engineering

Queueing theory optimizes resource allocation and reduces waiting times in manufacturing systems, material handling, and assembly lines by analyzing arrival rates and service processes. It is crucial for designing efficient production layouts, managing inventory flow, and minimizing bottlenecks in supply chain operations. Industrial engineers apply queueing models to improve system throughput, enhance customer service levels, and balance workloads across multiple service stations.

Scheduling Theory Applications in Manufacturing and Services

Scheduling theory optimizes task assignment and timing in manufacturing and service systems to improve resource utilization, reduce waiting times, and enhance overall efficiency. Applications include production line scheduling, workforce allocation, and maintenance planning, driving cost reductions and meeting delivery deadlines. Queueing theory complements this by analyzing system congestion and service processes, but scheduling theory directly addresses prioritization and sequencing for operational excellence.

Performance Metrics: Comparing Queueing and Scheduling

Queueing theory analyzes system performance by measuring metrics such as average wait time, queue length, and system utilization, focusing on stochastic arrival and service processes. Scheduling theory evaluates job completion times, throughput, and resource allocation efficiency, emphasizing deterministic or priority-based scheduling policies. Comparing both, queueing theory optimizes process flow under uncertainty, while scheduling theory maximizes task ordering and resource management for performance enhancement.

Integration of Queueing and Scheduling in System Design

Integration of queueing theory and scheduling theory in system design enhances performance by optimizing resource allocation and reducing waiting times. Queueing models provide analytical insights into traffic patterns and bottlenecks, while scheduling algorithms prioritize tasks based on these insights to improve throughput and service quality. Combining these approaches enables dynamic and efficient management of workloads in complex systems such as manufacturing lines, telecommunications, and computing networks.

Challenges in Implementing Queueing and Scheduling Solutions

Queueing theory faces challenges such as accurately modeling complex arrival patterns and service times in dynamic systems, which often lead to unpredictable bottlenecks. Scheduling theory struggles with optimizing resource allocation under constraints like varying priorities, deadlines, and the need for real-time adjustments. Both fields require balancing efficiency with fairness, scalability, and adaptability to changing workloads in practical implementations.

Future Trends in Queueing and Scheduling Theories for Industry

Future trends in queueing theory emphasize integrating machine learning algorithms to predict and manage dynamic service demands in real-time, enhancing operational efficiency in manufacturing and logistics. Scheduling theory advancements focus on adaptive algorithms that optimize resource allocation under uncertainty, leveraging IoT data to improve responsiveness in smart factories. Both fields converge toward developing hybrid models that combine stochastic analysis with AI-driven decision-making to support Industry 4.0's automation and flexibility requirements.

Arrival Rate vs. Job Sequencing

Queueing theory analyzes arrival rate to model system congestion, while scheduling theory optimizes job sequencing to improve task execution order and resource utilization.

Service Discipline vs. Dispatching Rules

Service discipline in queueing theory governs the order in which customers receive service, while dispatching rules in scheduling theory determine the sequence of job processing to optimize system performance.

Little’s Law vs. Makespan Optimization

Little's Law in queueing theory quantifies average system occupancy by relating arrival rate and waiting time, whereas scheduling theory's makespan optimization focuses on minimizing total completion time of tasks to improve resource utilization.

Traffic Intensity vs. Gantt Chart Analysis

Queueing theory evaluates system performance through traffic intensity metrics to measure workload and congestion, while scheduling theory utilizes Gantt chart analysis to optimize task sequencing and resource allocation.

Waiting Time Distribution vs. Flow Shop Scheduling

Queueing theory analyzes waiting time distribution to optimize system delays, while scheduling theory, especially flow shop scheduling, focuses on sequencing tasks to minimize total completion time and improve workflow efficiency.

Queue Stability vs. Due Date Assignment

Queue stability in queueing theory ensures system equilibrium by preventing infinite backlog, while due date assignment in scheduling theory optimizes task prioritization to meet deadlines.

Server Utilization vs. Load Balancing

Queueing theory analyzes server utilization by modeling system capacity and arrival rates, while scheduling theory optimizes load balancing to improve task allocation and resource efficiency.

Markovian Queues vs. Scheduling Heuristics

Markovian queues analyze stochastic arrival and service processes using memoryless properties for modeling system states, while scheduling heuristics optimize task order and resource allocation in deterministic or dynamic environments without relying on probabilistic assumptions.

Balking and Reneging vs. Tardiness Minimization

Queueing theory analyzes balking and reneging behaviors impacting system congestion and customer wait times, while scheduling theory focuses on minimizing tardiness to optimize task completion and resource utilization.

Queue Network Models vs. Resource-Constrained Scheduling

Queue Network Models analyze system performance through interconnected queues to optimize flow and waiting times, while Resource-Constrained Scheduling focuses on allocating limited resources efficiently to minimize project duration and meet deadlines.

queueing theory vs scheduling theory Infographic

njnir.com

njnir.com