Mass customization combines the efficiency of mass production with the flexibility of individualized products, enabling manufacturers to meet specific customer needs without sacrificing economies of scale. This approach leverages advanced technologies such as automation and digital design to streamline production processes while allowing for product variation. In contrast, traditional mass production focuses on large-scale manufacturing of standardized products, prioritizing volume and cost reduction over customization and responsiveness.

Table of Comparison

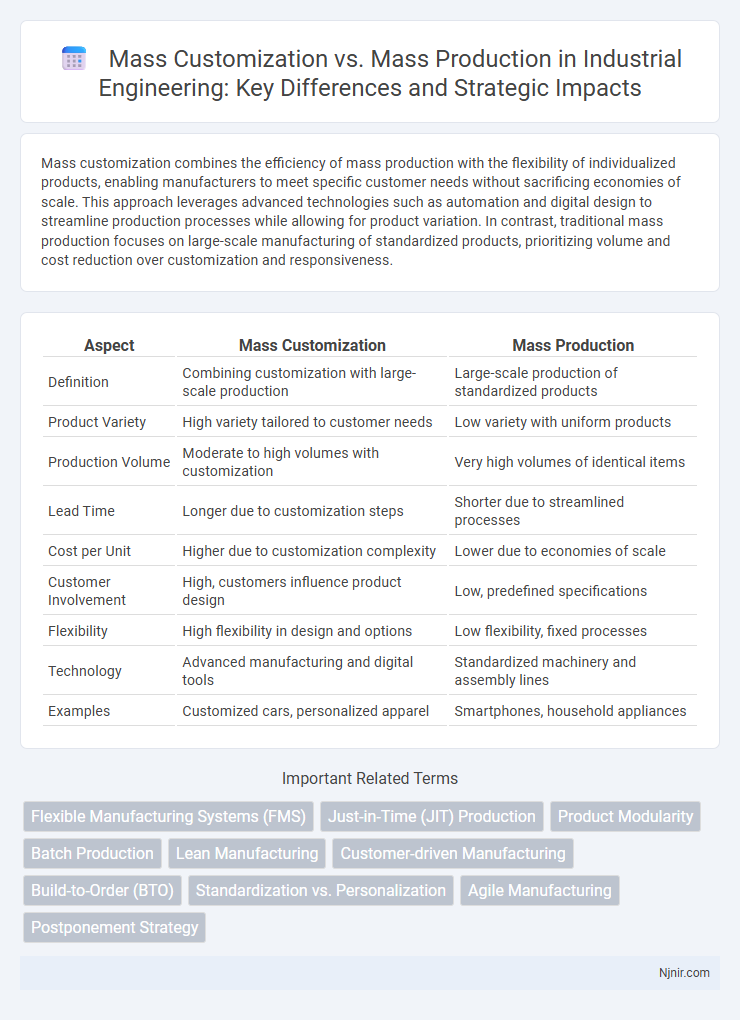

| Aspect | Mass Customization | Mass Production |

|---|---|---|

| Definition | Combining customization with large-scale production | Large-scale production of standardized products |

| Product Variety | High variety tailored to customer needs | Low variety with uniform products |

| Production Volume | Moderate to high volumes with customization | Very high volumes of identical items |

| Lead Time | Longer due to customization steps | Shorter due to streamlined processes |

| Cost per Unit | Higher due to customization complexity | Lower due to economies of scale |

| Customer Involvement | High, customers influence product design | Low, predefined specifications |

| Flexibility | High flexibility in design and options | Low flexibility, fixed processes |

| Technology | Advanced manufacturing and digital tools | Standardized machinery and assembly lines |

| Examples | Customized cars, personalized apparel | Smartphones, household appliances |

Understanding Mass Customization and Mass Production

Mass customization combines the flexibility of custom-made products with the low unit costs of mass production, allowing businesses to meet individual customer preferences at scale through advanced manufacturing technologies and modular design. Mass production relies on standardized processes and economies of scale to produce large volumes of identical products efficiently, minimizing costs and maximizing output. Understanding the trade-offs between customization and standardization is essential for companies aiming to balance responsiveness to market demand with operational efficiency.

Historical Evolution of Manufacturing Paradigms

Mass production emerged during the Industrial Revolution, revolutionizing manufacturing by standardizing products and maximizing efficiency through assembly line techniques pioneered by Henry Ford. In contrast, mass customization evolved in the late 20th century, driven by advancements in digital technologies and flexible manufacturing systems that enabled personalized products at near mass production costs. This shift reflects a transformation from economies of scale to economies of scope, addressing diverse consumer preferences without sacrificing efficiency.

Key Principles of Mass Production

Mass production relies on standardized processes, high volume output, and economies of scale to achieve cost efficiency and uniformity. Key principles include assembly line techniques, specialized labor, and continuous flow production to minimize variability and maximize productivity. This approach contrasts with mass customization, which prioritizes personalized products at scale by leveraging flexible manufacturing systems.

Defining Features of Mass Customization

Mass customization combines the personalization of individual products with the efficiency of mass production, offering tailored items that meet specific customer preferences without significant cost increases. Key features include modular product design, flexible manufacturing systems, and advanced information technology to capture and implement customer requirements. This approach enhances customer satisfaction and competitiveness by delivering unique products at near mass-production scale and prices.

Technological Enablers in Modern Manufacturing

Technological enablers such as advanced robotics, additive manufacturing, and AI-driven design systems empower mass customization by allowing flexible production lines and real-time adaptation to individual customer specifications. In contrast, mass production relies heavily on automation technologies like conveyor systems and fixed tooling to maximize efficiency and output at scale. The integration of IoT and digital twins further bridges the gap, enhancing precision and responsiveness in both manufacturing paradigms.

Cost Structures: Comparing Economies of Scale

Mass production achieves low unit costs through economies of scale by producing large volumes with standardized processes and materials, minimizing fixed and variable expenses per unit. In contrast, mass customization incurs higher costs due to flexible manufacturing systems, increased setup times, and more complex supply chains that accommodate individualized products. While mass customization reduces inventory and enhances customer value, its cost structure is less efficient than mass production, making it ideal for niche markets rather than high-volume output.

Flexibility and Lead Time Considerations

Mass customization offers greater flexibility by allowing tailored products to meet specific customer preferences, adjusting designs and production processes rapidly. In contrast, mass production prioritizes efficiency and volume but has limited flexibility due to standardized products and repetitive manufacturing steps. Lead time for mass customization varies based on order complexity, often longer than the shorter, consistent lead times achieved in mass production through streamlined assembly lines.

Impact on Supply Chain and Inventory Management

Mass customization demands a flexible supply chain capable of rapid adjustments and real-time inventory tracking to accommodate diverse customer specifications, whereas mass production relies on streamlined, high-volume processes with standardized inventory. The complexity of mass customization increases supply chain responsiveness requirements and inventory variability, leading to higher logistical coordination and cost management challenges. In contrast, mass production benefits from economies of scale, predictable inventory levels, and simplified procurement strategies, resulting in lower per-unit costs and consistent supply chain performance.

Quality Control and Product Personalization

Mass customization integrates advanced quality control mechanisms through flexible manufacturing systems, enabling tailored products without compromising consistency. In contrast, mass production emphasizes standardized quality control processes to maintain uniformity across large production volumes, often limiting personalization. The balance between product personalization and quality control defines the competitive edge in consumer satisfaction and operational efficiency.

Future Trends in Industrial Engineering Practices

Mass customization is driving the future of industrial engineering by integrating advanced technologies such as AI, IoT, and additive manufacturing to create highly personalized products at near mass production costs. Industrial engineering practices are increasingly adopting data analytics and flexible manufacturing systems to enhance efficiency and responsiveness to dynamic market demands. This shift from traditional mass production to mass customization supports sustainable production models and improved customer satisfaction through tailored products and scalable operations.

Flexible Manufacturing Systems (FMS)

Flexible Manufacturing Systems (FMS) enhance mass customization by enabling efficient production of diverse, customized products with rapid changeover, contrasting traditional mass production's emphasis on high-volume, standardized output.

Just-in-Time (JIT) Production

Just-in-Time (JIT) production enhances mass customization by minimizing inventory and enabling flexible manufacturing, whereas mass production prioritizes standardized output with larger inventories and less responsiveness to individual customer demands.

Product Modularity

Product modularity enables mass customization by allowing flexible combinations of standardized components, whereas mass production relies on rigid, uniform product designs to maximize efficiency.

Batch Production

Batch production balances the efficiency of mass production with the flexibility of mass customization by producing goods in specific groups to meet varied customer demands.

Lean Manufacturing

Lean manufacturing enhances mass customization by minimizing waste and enabling flexible production processes, whereas mass production emphasizes high-volume output with standardized products.

Customer-driven Manufacturing

Mass customization leverages customer-driven manufacturing to tailor products to individual preferences, enhancing satisfaction and market responsiveness unlike traditional mass production's standardized output.

Build-to-Order (BTO)

Build-to-Order (BTO) in mass customization enables tailored product manufacturing based on individual customer specifications, contrasting with mass production's standardized, large-scale output that prioritizes efficiency over personalization.

Standardization vs. Personalization

Mass customization balances personalization with standardized processes to offer unique products at scale, whereas mass production emphasizes strict standardization for maximum efficiency and uniformity.

Agile Manufacturing

Agile manufacturing leverages mass customization by enabling rapid adaptation to customer-specific demands, contrasting with the rigidity of traditional mass production focused on standardized products.

Postponement Strategy

The Postponement Strategy enhances mass customization by delaying product differentiation until the final stage, reducing inventory costs and increasing flexibility compared to traditional mass production.

Mass customization vs Mass production Infographic

njnir.com

njnir.com