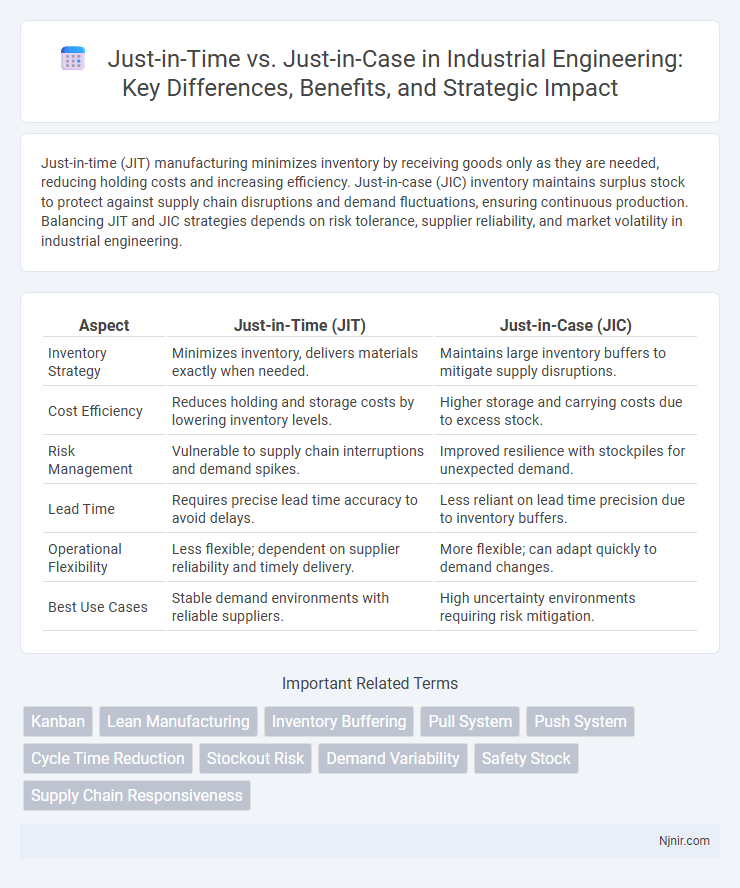

Just-in-time (JIT) manufacturing minimizes inventory by receiving goods only as they are needed, reducing holding costs and increasing efficiency. Just-in-case (JIC) inventory maintains surplus stock to protect against supply chain disruptions and demand fluctuations, ensuring continuous production. Balancing JIT and JIC strategies depends on risk tolerance, supplier reliability, and market volatility in industrial engineering.

Table of Comparison

| Aspect | Just-in-Time (JIT) | Just-in-Case (JIC) |

|---|---|---|

| Inventory Strategy | Minimizes inventory, delivers materials exactly when needed. | Maintains large inventory buffers to mitigate supply disruptions. |

| Cost Efficiency | Reduces holding and storage costs by lowering inventory levels. | Higher storage and carrying costs due to excess stock. |

| Risk Management | Vulnerable to supply chain interruptions and demand spikes. | Improved resilience with stockpiles for unexpected demand. |

| Lead Time | Requires precise lead time accuracy to avoid delays. | Less reliant on lead time precision due to inventory buffers. |

| Operational Flexibility | Less flexible; dependent on supplier reliability and timely delivery. | More flexible; can adapt quickly to demand changes. |

| Best Use Cases | Stable demand environments with reliable suppliers. | High uncertainty environments requiring risk mitigation. |

Introduction to Just-in-Time and Just-in-Case Systems

Just-in-Time (JIT) systems emphasize minimizing inventory by receiving goods only as they are needed in the production process, reducing storage costs and waste. Just-in-Case (JIC) systems prioritize maintaining extra inventory to prevent stockouts and ensure production continuity during supply chain disruptions. Understanding these inventory management strategies is crucial for optimizing supply chain efficiency and balancing cost control with risk mitigation.

Historical Evolution of Inventory Management Strategies

Just-in-time (JIT) inventory management emerged in the 1970s through Toyota's production system, revolutionizing manufacturing by minimizing stock levels and reducing waste. Just-in-case (JIC) inventory strategies predate JIT, rooted in traditional stockpiling methods to mitigate supply chain disruptions and demand fluctuations. The historical shift from JIC to JIT reflects advancements in technology, data analytics, and lean manufacturing principles that prioritize efficiency and cost reduction.

Core Principles of Just-in-Time (JIT)

Just-in-Time (JIT) inventory management centers on minimizing waste by receiving goods only as they are needed in the production process, reducing inventory holding costs and enhancing efficiency. The core principles include continuous flow production, pull systems driven by actual demand rather than forecasts, and strong supplier relationships to ensure timely deliveries. Emphasizing quality control and employee involvement further supports JIT's goal of streamlining operations and improving responsiveness to customer requirements.

Core Principles of Just-in-Case (JIC)

Just-in-Case (JIC) inventory management is centered on maintaining high stock levels to mitigate risks of supply chain disruptions, demand fluctuations, or unforeseen events. Its core principles emphasize safety stock accumulation, risk aversion, and readiness for variability by holding excess inventory as a buffer. This approach prioritizes reliability and continuous availability over cost efficiency by safeguarding against uncertainties.

Comparative Analysis: JIT vs. JIC in Industrial Engineering

Just-in-time (JIT) manufacturing minimizes inventory by producing goods only as needed, reducing waste and lowering holding costs, whereas Just-in-case (JIC) prioritizes buffer stock to mitigate supply chain disruptions, ensuring production continuity. JIT enhances operational efficiency and responsiveness but is vulnerable to supply delays, while JIC increases inventory investment and potential obsolescence but offers robust risk management against demand fluctuations. Industrial engineering applications balance JIT's lean principles with JIC's risk mitigation, optimizing production systems through demand forecasting accuracy and supplier reliability.

Benefits and Limitations of JIT in Manufacturing

Just-in-time (JIT) manufacturing reduces inventory costs and minimizes waste by producing goods only as needed, improving cash flow and operational efficiency. Limitations of JIT include vulnerability to supply chain disruptions and demand fluctuations, which can lead to production delays and stockouts. Successful implementation requires robust supplier relationships and precise demand forecasting to balance efficiency with risk management.

Advantages and Drawbacks of JIC in Operations

Just-in-case (JIC) inventory management ensures operational resilience by maintaining buffer stocks to prevent stockouts, enhancing service levels during demand fluctuations and supply chain disruptions. This approach, however, incurs higher holding costs and risks inventory obsolescence due to excess stock. The trade-off between increased safety stock and elevated carrying costs makes JIC suitable for industries with unpredictable demand or long lead times.

Risk Management: Supply Chain Resilience in JIT vs. JIC

Just-in-time (JIT) emphasizes minimizing inventory to reduce costs but increases vulnerability to supply chain disruptions, requiring robust risk mitigation strategies such as real-time demand forecasting and supplier diversification. Just-in-case (JIC) maintains higher inventory levels as a buffer against uncertainties, enhancing supply chain resilience by ensuring product availability during disruptions at the expense of higher holding costs. Supply chain risk management in JIT relies heavily on agility and transparency, while JIC focuses on redundancy and preparedness to withstand unexpected events.

Industry Case Studies: Practical Applications of JIT and JIC

Industry case studies highlight how Toyota revolutionized manufacturing with Just-in-Time (JIT), minimizing inventory costs by synchronizing production closely with demand. Conversely, companies like Walmart employ Just-in-Case (JIC) strategies to maintain robust inventory levels that mitigate supply chain disruptions during peak seasons. Pharmaceutical firms balance JIT's efficiency with JIC's risk management by stockpiling critical drugs to ensure availability amidst unpredictable demand fluctuations.

Future Trends in Inventory Management: Integrating JIT and JIC

Future trends in inventory management emphasize the integration of Just-in-Time (JIT) and Just-in-Case (JIC) strategies to balance efficiency and risk mitigation. Advanced AI-driven analytics enable dynamic adjustments between lean JIT processes and safety stock buffers of JIC, optimizing supply chain responsiveness. This hybrid approach supports resilience against disruptions while minimizing holding costs, driving more adaptive and predictive inventory control systems.

Kanban

Kanban optimizes inventory and workflow through Just-in-time principles, minimizing waste by signaling demand only when needed rather than maintaining excess stock as in Just-in-case strategies.

Lean Manufacturing

Just-in-time (JIT) in Lean Manufacturing minimizes inventory and reduces waste by producing goods only as needed, whereas Just-in-case (JIC) maintains excess stock to buffer against uncertainties, often leading to higher holding costs and inefficiencies.

Inventory Buffering

Just-in-time inventory buffering minimizes stock levels by synchronizing supply with demand, while just-in-case buffering maintains excess inventory to mitigate supply chain disruptions.

Pull System

The Pull System in Just-in-time inventory management minimizes waste by producing goods only in response to actual demand, contrasting with the stockpiling approach of Just-in-case strategies.

Push System

Push systems in Just-in-case inventory management produce goods based on forecasted demand to maintain safety stock, contrasting with Just-in-time's demand-driven pull approach.

Cycle Time Reduction

Just-in-time inventory management minimizes cycle time by synchronizing production schedules with demand, while just-in-case prioritizes stockpiling, often extending cycle times due to excess inventory handling.

Stockout Risk

Just-in-time inventory systems minimize stockout risk by synchronizing supply with demand, while Just-in-case strategies reduce stockout risk through maintaining higher buffer stock levels.

Demand Variability

Just-in-time inventory reduces costs by aligning production with low-demand variability, while just-in-case inventory mitigates risk by accommodating high-demand variability through excess stock.

Safety Stock

Just-in-time minimizes safety stock by synchronizing inventory with demand, while just-in-case maintains higher safety stock to buffer against supply chain uncertainties.

Supply Chain Responsiveness

Just-in-time supply chains enhance responsiveness by minimizing inventory and enabling rapid adaptation to demand fluctuations, while just-in-case strategies prioritize buffer stock to mitigate supply disruptions but may reduce flexibility.

Just-in-time vs Just-in-case Infographic

njnir.com

njnir.com