A pull system in industrial engineering reduces inventory waste by producing items only when there is customer demand, improving efficiency and responsiveness. In contrast, a push system relies on forecast-driven production, often leading to excess inventory and increased lead times. Implementing a pull system enhances lean manufacturing practices by minimizing overproduction and aligning production closely with actual demand.

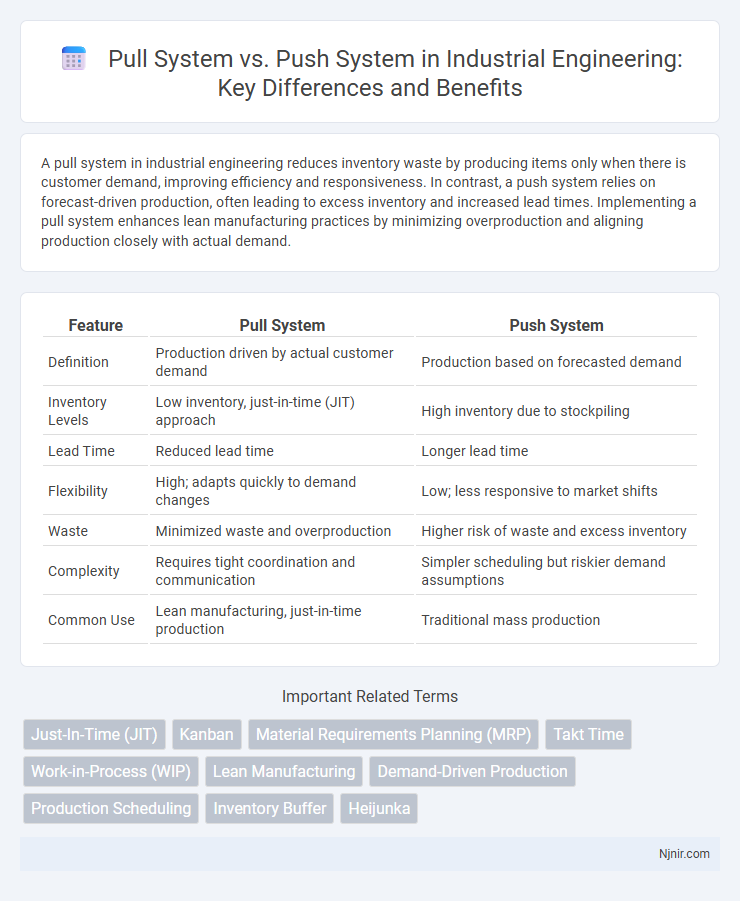

Table of Comparison

| Feature | Pull System | Push System |

|---|---|---|

| Definition | Production driven by actual customer demand | Production based on forecasted demand |

| Inventory Levels | Low inventory, just-in-time (JIT) approach | High inventory due to stockpiling |

| Lead Time | Reduced lead time | Longer lead time |

| Flexibility | High; adapts quickly to demand changes | Low; less responsive to market shifts |

| Waste | Minimized waste and overproduction | Higher risk of waste and excess inventory |

| Complexity | Requires tight coordination and communication | Simpler scheduling but riskier demand assumptions |

| Common Use | Lean manufacturing, just-in-time production | Traditional mass production |

Introduction to Pull and Push Systems in Industrial Engineering

Pull and push systems represent two fundamental production control strategies in industrial engineering. A pull system initiates production based on actual demand, minimizing inventory and reducing waste through just-in-time manufacturing principles. Conversely, a push system relies on forecasted demand to drive production, often resulting in higher inventory levels and increased risk of overproduction.

Core Principles of Pull Systems

Pull systems operate on the core principle of producing goods or services only in response to actual customer demand, minimizing inventory levels and reducing waste. Key elements include just-in-time production, continuous flow, and demand-driven replenishment, ensuring resources are efficiently allocated and lead times shortened. This approach enhances flexibility and responsiveness, aligning production closely with real-time consumption patterns.

Essential Concepts of Push Systems

Push systems operate on forecasted demand, where production and inventory decisions are made based on predicted customer orders, often leading to higher inventory levels. This system relies on scheduled workflows and predefined production plans, which can result in excess stock or stockouts if forecasts are inaccurate. Key metrics include inventory turnover rates and forecast accuracy, critical for optimizing the push system's efficiency and reducing carrying costs.

Key Differences Between Pull and Push Approaches

The pull system is driven by actual customer demand, triggering production only when there is a real need, which minimizes inventory and reduces waste. The push system relies on forecasted demand, producing goods in advance and pushing them through the supply chain, often leading to excess inventory and higher storage costs. Key differences include responsiveness to demand, inventory levels, and production scheduling, with pull systems emphasizing lean manufacturing principles and push systems focusing on mass production and forecasting accuracy.

Advantages of Pull Systems in Manufacturing

Pull systems in manufacturing minimize inventory levels by producing goods only in response to actual demand, reducing waste and storage costs. This approach enhances production flexibility and improves quality control through real-time feedback and continuous improvement processes. By aligning production with customer orders, pull systems also shorten lead times and increase overall operational efficiency.

Benefits and Challenges of Push Systems

Push systems enhance production efficiency by scheduling based on forecasted demand, allowing companies to maintain consistent workflow and optimize inventory levels. However, challenges include the risk of overproduction, increased inventory holding costs, and reduced flexibility to respond to actual market fluctuations. Managing these risks requires accurate demand forecasting and robust supply chain coordination to prevent waste and obsolescence.

Impact on Inventory Management and Lead Times

A pull system reduces inventory levels by producing goods only in response to actual demand, minimizing excess stock and decreasing carrying costs. In contrast, a push system relies on forecast-driven production, often resulting in higher inventory levels and increased risk of obsolescence. Lead times in a pull system tend to be shorter and more responsive to market changes, while push systems typically experience longer lead times due to batch production and stockpiling.

Implementation Considerations for Pull and Push Systems

Implementing a pull system requires precise demand forecasting and real-time inventory management to minimize overproduction and reduce waste, making it ideal for just-in-time manufacturing environments. Push systems rely heavily on accurate production scheduling and capacity planning to maintain consistent output and meet forecasted demand, often leading to higher inventory levels. Both systems necessitate robust ERP integration and clear communication channels to optimize workflow efficiency and respond swiftly to market changes.

Case Studies: Pull vs Push in Industrial Settings

Case studies in industrial settings reveal that pull systems significantly improve inventory turnover and reduce waste compared to push systems, particularly in lean manufacturing environments like Toyota Production System. In automotive assembly lines, companies adopting pull strategies report enhanced responsiveness to demand fluctuations and increased operational efficiency. Push systems often lead to overproduction and higher carrying costs, whereas pull systems align production closely with real-time customer demand, optimizing resource utilization.

Choosing the Right System: Strategic Recommendations

Choosing the right production system depends on demand variability and inventory costs, with pull systems excelling in environments requiring high flexibility and minimal waste due to real-time demand signals. Push systems suit stable demand scenarios by enabling forecast-driven production and bulk inventory management, optimizing economies of scale. Strategic recommendations emphasize analyzing customer demand patterns, lead times, and supply chain responsiveness to align system choice with operational efficiency and cost reduction goals.

Just-In-Time (JIT)

The Pull system, central to Just-In-Time (JIT) manufacturing, reduces inventory by producing goods based on actual demand, while the Push system forecasts demand and produces in advance, often leading to excess inventory and inefficiencies.

Kanban

The Kanban pull system optimizes workflow by signaling tasks based on actual demand, contrasting with the push system's pre-planned task assignments that can cause overproduction and inefficiencies.

Material Requirements Planning (MRP)

The Pull system enhances inventory efficiency by producing goods based on actual demand, while the Push system driven by Material Requirements Planning (MRP) schedules production based on forecasted demand and planned orders.

Takt Time

Pull systems synchronize production with Takt Time to minimize inventory and respond directly to customer demand, while Push systems schedule production based on forecasts without strict adherence to Takt Time, often leading to overproduction.

Work-in-Process (WIP)

Pull systems minimize Work-in-Process (WIP) by producing only what is needed based on customer demand, whereas Push systems often result in higher WIP due to scheduled production regardless of current demand.

Lean Manufacturing

The Pull system in Lean Manufacturing minimizes inventory and reduces waste by producing only what is needed based on real-time demand, unlike the Push system which relies on forecast-driven production leading to excess inventory and inefficiencies.

Demand-Driven Production

Demand-driven production in a pull system minimizes inventory waste by producing goods only in response to actual customer demand, whereas push systems rely on forecast-based production that often leads to excess stock and inefficiencies.

Production Scheduling

The pull system in production scheduling minimizes inventory and reduces lead times by initiating production based on actual demand, whereas the push system schedules production according to forecasted demand, often resulting in higher inventory levels and potential overproduction.

Inventory Buffer

A Pull system minimizes inventory buffers by producing goods based on actual demand, while a Push system relies on forecasted demand, often resulting in larger inventory buffers.

Heijunka

Heijunka, a key Lean manufacturing technique, optimizes production flow by leveling workload and reducing inventory in a pull system, contrasting with push systems that often lead to overproduction and inefficiencies.

Pull system vs Push system Infographic

njnir.com

njnir.com