IIoT (Industrial Internet of Things) emphasizes the integration of smart sensors and connected devices to enhance machine-to-machine communication and real-time data analytics in industrial settings. Industry 4.0 represents a broader systemic transformation incorporating IIoT alongside cyber-physical systems, cloud computing, and artificial intelligence to create fully automated, intelligent factories. The synergy between IIoT and Industry 4.0 drives increased operational efficiency, predictive maintenance, and flexible manufacturing processes.

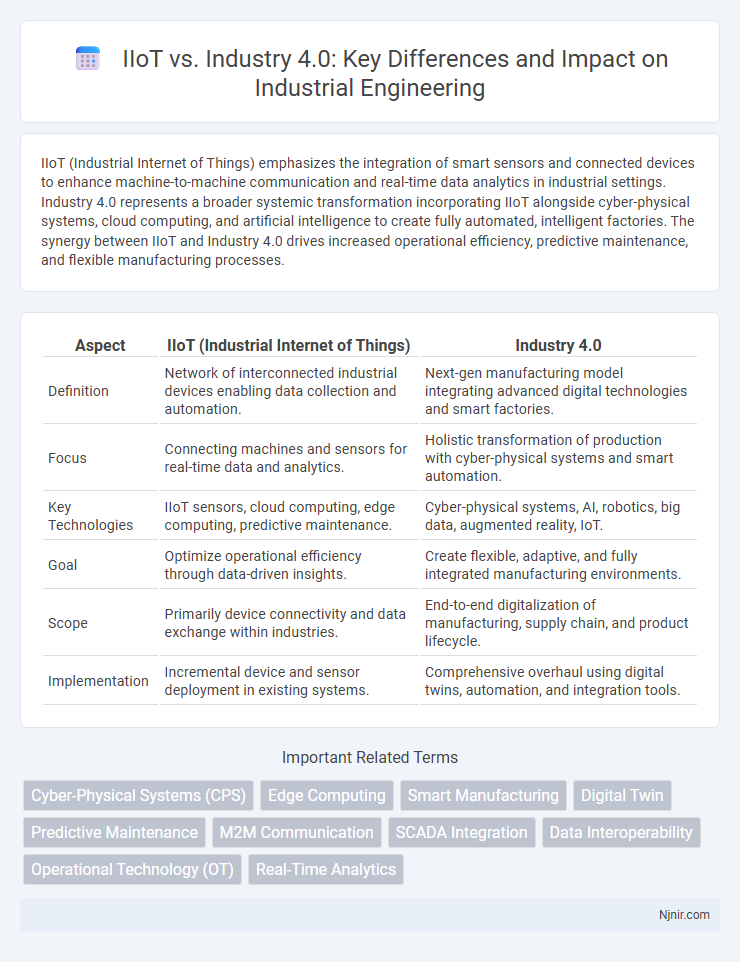

Table of Comparison

| Aspect | IIoT (Industrial Internet of Things) | Industry 4.0 |

|---|---|---|

| Definition | Network of interconnected industrial devices enabling data collection and automation. | Next-gen manufacturing model integrating advanced digital technologies and smart factories. |

| Focus | Connecting machines and sensors for real-time data and analytics. | Holistic transformation of production with cyber-physical systems and smart automation. |

| Key Technologies | IIoT sensors, cloud computing, edge computing, predictive maintenance. | Cyber-physical systems, AI, robotics, big data, augmented reality, IoT. |

| Goal | Optimize operational efficiency through data-driven insights. | Create flexible, adaptive, and fully integrated manufacturing environments. |

| Scope | Primarily device connectivity and data exchange within industries. | End-to-end digitalization of manufacturing, supply chain, and product lifecycle. |

| Implementation | Incremental device and sensor deployment in existing systems. | Comprehensive overhaul using digital twins, automation, and integration tools. |

Defining IIoT and Industry 4.0

IIoT, or Industrial Internet of Things, refers to the network of interconnected sensors, devices, and machines within industrial environments that collect and exchange data to enhance operational efficiency. Industry 4.0 encompasses a broader concept, integrating IIoT with advanced technologies such as artificial intelligence, big data analytics, and cyber-physical systems to create smart factories and highly automated manufacturing processes. The core distinction lies in IIoT focusing on connectivity and data acquisition, while Industry 4.0 targets comprehensive digital transformation in industrial production.

Key Differences Between IIoT and Industry 4.0

IIoT (Industrial Internet of Things) primarily focuses on connecting industrial devices and sensors to collect and analyze data for improving operational efficiency and predictive maintenance. Industry 4.0 encompasses a broader transformation, integrating cyber-physical systems, automation, data exchange, and smart manufacturing processes beyond just connectivity. Key differences lie in IIoT being a component of Industry 4.0's larger ecosystem, with Industry 4.0 emphasizing a comprehensive digital revolution across industrial production and supply chains.

Historical Evolution: IIoT vs Industry 4.0

IIoT originated in the early 2000s, focusing on connecting industrial devices and machinery through sensors and networks to improve operational efficiency. Industry 4.0 emerged later, around 2011, encompassing a broader framework that integrates digital technologies such as cyber-physical systems, IoT, artificial intelligence, and big data analytics to create smart factories. While IIoT centers on device connectivity and data collection, Industry 4.0 represents a holistic transformation of manufacturing processes driven by automation and real-time data integration.

Core Technologies Driving IIoT and Industry 4.0

Core technologies driving IIoT and Industry 4.0 include advanced sensors, edge computing, and artificial intelligence, enabling real-time data collection, processing, and predictive analytics. Industrial Ethernet, 5G connectivity, and cloud platforms facilitate seamless communication and integration across manufacturing systems, enhancing operational efficiency. Cyber-physical systems, digital twins, and automation technologies further empower smart factories with adaptive, autonomous decision-making and optimized production workflows.

Industrial Applications of IIoT

Industrial Internet of Things (IIoT) enables real-time data collection and analysis across manufacturing equipment, optimizing performance and predictive maintenance within Industry 4.0 frameworks. Applications of IIoT include asset tracking, remote equipment monitoring, and process automation, which enhance operational efficiency and reduce downtime in smart factories. The integration of IIoT with Industry 4.0 technologies such as AI, big data, and cloud computing drives advanced industrial automation and superior decision-making.

Industry 4.0 in Manufacturing Environments

Industry 4.0 revolutionizes manufacturing environments by integrating cyber-physical systems, the Industrial Internet of Things (IIoT), and advanced data analytics to create smart factories with enhanced automation, real-time monitoring, and predictive maintenance capabilities. This paradigm shift enables seamless communication between machines, systems, and humans, optimizing production processes, reducing downtime, and improving overall operational efficiency. Industry 4.0 leverages big data, artificial intelligence, and edge computing to transform traditional manufacturing into highly flexible, adaptive, and intelligent ecosystems.

Data Analytics and Connectivity in IIoT vs Industry 4.0

IIoT emphasizes real-time data analytics and machine-to-machine connectivity to optimize industrial processes through sensor networks and edge computing. Industry 4.0 integrates IIoT with advanced cybersecurity, cloud computing, and artificial intelligence to enable smart factories and autonomous decision-making systems. Data connectivity in Industry 4.0 relies on heterogeneous networks and interoperable protocols to support seamless communication across diverse industrial devices and platforms.

Benefits and Challenges of Adopting IIoT and Industry 4.0

IIoT enhances operational efficiency, predictive maintenance, and real-time data analytics by connecting industrial devices, while Industry 4.0 integrates IIoT with cyber-physical systems, automation, and AI to create smart factories. Benefits of adopting IIoT and Industry 4.0 include improved asset utilization, reduced downtime, and supply chain optimization, but challenges involve cybersecurity risks, high implementation costs, and workforce skill gaps. Successful adoption requires robust data management, scalable infrastructure, and continuous employee training to overcome integration hurdles and maximize technological advantages.

Integration Strategies for IIoT and Industry 4.0

Integration strategies for IIoT and Industry 4.0 emphasize seamless connectivity between industrial devices and intelligent systems through edge computing and cloud platforms. Leveraging standardized communication protocols like OPC UA and MQTT enables real-time data exchange, enhancing automation and predictive maintenance. Combining AI-driven analytics with robust cybersecurity frameworks ensures scalable, interoperable, and secure industrial ecosystems.

Future Trends and Predictions in Industrial Engineering

Future trends in IIoT emphasize enhanced connectivity through 5G integration, enabling real-time data analytics and predictive maintenance in industrial engineering. Industry 4.0 predictions highlight increased adoption of AI-driven automation, digital twins, and augmented reality to optimize manufacturing processes and supply chain management. Both paradigms drive smart factory evolution by leveraging cyber-physical systems and edge computing for improved operational efficiency and sustainability.

Cyber-Physical Systems (CPS)

Cyber-Physical Systems (CPS) serve as the foundational technology in Industry 4.0 by integrating IIoT sensors, networks, and data analytics to enable real-time monitoring, automation, and smart manufacturing processes.

Edge Computing

Edge computing in IIoT enables real-time data processing at the source, enhancing Industry 4.0 automation, efficiency, and reduced latency in smart manufacturing systems.

Smart Manufacturing

IIoT enables real-time data connectivity and automation in Smart Manufacturing, while Industry 4.0 integrates IIoT with cyber-physical systems, AI, and big data analytics to create fully optimized, intelligent production environments.

Digital Twin

Digital Twin technology in Industry 4.0 leverages IIoT data to create real-time virtual replicas of physical assets, enhancing predictive maintenance and operational efficiency.

Predictive Maintenance

Predictive maintenance leverages IIoT sensors and real-time data analytics to enhance Industry 4.0's smart factory operations by minimizing downtime and optimizing equipment performance.

M2M Communication

M2M communication in IIoT enables real-time data exchange between industrial devices, forming the core connectivity layer that drives Industry 4.0's smart factory automation and predictive maintenance capabilities.

SCADA Integration

SCADA integration in IIoT enhances real-time data acquisition and remote monitoring, driving Industry 4.0's smart manufacturing and predictive maintenance capabilities.

Data Interoperability

IIoT enhances Data Interoperability by integrating sensor-level data streams across devices, while Industry 4.0 emphasizes standardized protocols and cross-industry platforms to achieve seamless data exchange and smart manufacturing integration.

Operational Technology (OT)

Industrial Internet of Things (IIoT) integrates connected sensors and devices into Operational Technology (OT) systems to enhance real-time data analytics and automation, while Industry 4.0 encompasses a broader digital transformation including smart manufacturing, cyber-physical systems, and advanced OT-IT convergence.

Real-Time Analytics

Real-Time Analytics in IIoT enables instantaneous data processing from connected industrial devices, enhancing Industry 4.0's smart manufacturing efficiency and predictive maintenance capabilities.

IIoT vs Industry 4.0 Infographic

njnir.com

njnir.com