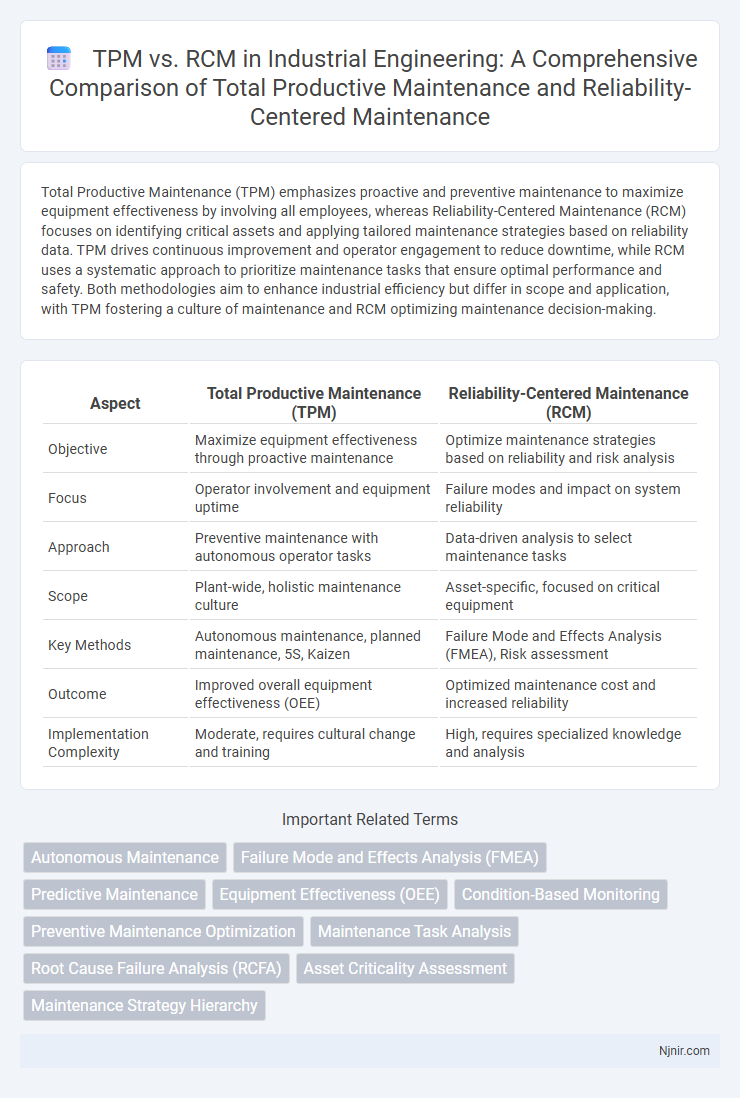

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance to maximize equipment effectiveness by involving all employees, whereas Reliability-Centered Maintenance (RCM) focuses on identifying critical assets and applying tailored maintenance strategies based on reliability data. TPM drives continuous improvement and operator engagement to reduce downtime, while RCM uses a systematic approach to prioritize maintenance tasks that ensure optimal performance and safety. Both methodologies aim to enhance industrial efficiency but differ in scope and application, with TPM fostering a culture of maintenance and RCM optimizing maintenance decision-making.

Table of Comparison

| Aspect | Total Productive Maintenance (TPM) | Reliability-Centered Maintenance (RCM) |

|---|---|---|

| Objective | Maximize equipment effectiveness through proactive maintenance | Optimize maintenance strategies based on reliability and risk analysis |

| Focus | Operator involvement and equipment uptime | Failure modes and impact on system reliability |

| Approach | Preventive maintenance with autonomous operator tasks | Data-driven analysis to select maintenance tasks |

| Scope | Plant-wide, holistic maintenance culture | Asset-specific, focused on critical equipment |

| Key Methods | Autonomous maintenance, planned maintenance, 5S, Kaizen | Failure Mode and Effects Analysis (FMEA), Risk assessment |

| Outcome | Improved overall equipment effectiveness (OEE) | Optimized maintenance cost and increased reliability |

| Implementation Complexity | Moderate, requires cultural change and training | High, requires specialized knowledge and analysis |

Introduction to TPM and RCM in Industrial Engineering

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance to maximize equipment effectiveness by involving all employees in continuous improvement and reducing downtime. Reliability-Centered Maintenance (RCM) focuses on identifying and prioritizing maintenance tasks based on equipment reliability and failure modes to optimize maintenance resources and enhance system availability. Both TPM and RCM are essential industrial engineering strategies aimed at improving operational efficiency and equipment lifecycle management while minimizing maintenance costs.

Core Principles of Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance to maximize equipment effectiveness by involving all employees in maintaining and improving production systems. TPM's core principles include Autonomous Maintenance, where operators carry out daily maintenance tasks to prevent breakdowns, and Planned Maintenance, focusing on scheduling maintenance activities to reduce downtime. Continuous improvement and cross-functional teamwork enhance overall equipment efficiency, aiming to achieve zero defects, zero breakdowns, and zero accidents.

Core Principles of Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) centers on identifying critical assets and selecting maintenance strategies that preserve their functions, emphasizing failure mode analysis and risk prioritization. Core principles include understanding asset function, assessing potential failures and their consequences, and implementing targeted maintenance tasks to mitigate risks while optimizing reliability. Unlike Total Productive Maintenance (TPM), which focuses broadly on operator involvement and equipment productivity, RCM prioritizes systematic decision-making based on reliability and safety data.

Key Objectives: TPM vs RCM

Total Productive Maintenance (TPM) focuses on maximizing overall equipment effectiveness (OEE) by involving all employees in proactive and preventive maintenance to reduce downtime and enhance productivity. Reliability-Centered Maintenance (RCM) aims to optimize maintenance strategies based on the reliability and criticality of assets, ensuring safety, operational continuity, and cost-effectiveness. TPM emphasizes equipment uptime and operator involvement, while RCM prioritizes failure analysis and tailored maintenance plans to maintain system reliability.

Methodologies and Implementation Steps

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance involving all employees to maximize equipment effectiveness through eight pillars such as autonomous maintenance and planned maintenance. Reliability-Centered Maintenance (RCM) focuses on identifying critical assets and failure modes to develop optimized maintenance strategies based on reliability data and risk assessment. Implementation of TPM typically starts with operator training and autonomous maintenance, while RCM involves detailed failure mode effects analysis (FMEA), prioritization of maintenance tasks, and continuous monitoring of asset health.

Impact on Equipment Reliability and Efficiency

Total Productive Maintenance (TPM) enhances equipment reliability by involving all employees in proactive maintenance activities, reducing downtime and improving overall equipment efficiency through continuous, routine inspections. Reliability-Centered Maintenance (RCM) emphasizes identifying critical failure modes and applying tailored maintenance strategies, ensuring optimal reliability by focusing resources on high-risk components. TPM boosts overall equipment effectiveness with a broad, organization-wide approach, while RCM targets reliability through data-driven, risk-prioritized maintenance interventions.

Human Factors: Roles in TPM and RCM

TPM emphasizes active involvement of all employees, from operators to maintenance teams, encouraging proactive maintenance and ownership of equipment reliability to prevent breakdowns. RCM focuses more on specialized maintenance personnel who analyze failure modes and optimize maintenance strategies based on equipment criticality and risk assessments. Human roles in TPM are geared towards continuous improvement and equipment care at the operational level, whereas RCM assigns technical decision-making to experts to ensure system reliability and safety.

Cost Implications and ROI Analysis

Total Productive Maintenance (TPM) emphasizes proactive equipment upkeep to minimize downtime, leading to reduced maintenance costs and improved operational efficiency, thereby enhancing ROI through increased production output. Reliability-Centered Maintenance (RCM) focuses on identifying critical assets and applying targeted maintenance strategies, optimizing resource allocation and lowering lifecycle costs, which can result in significant long-term financial savings. Comparing cost implications, TPM tends to generate quicker ROI via broad process improvements, while RCM delivers higher value in complex systems by prioritizing reliability and minimizing failure-related expenses.

Case Studies: TPM and RCM in Manufacturing

Case studies in manufacturing reveal that Total Productive Maintenance (TPM) significantly improves equipment efficiency by engaging operators in routine maintenance, leading to a 25% increase in Overall Equipment Effectiveness (OEE). Reliability-Centered Maintenance (RCM) focuses on identifying critical assets and applying targeted maintenance strategies, resulting in a 30% reduction in unexpected downtime in automotive factories. Combining TPM's operator-driven approach with RCM's data-driven asset prioritization creates a robust maintenance framework enhancing productivity and reliability.

Choosing the Right Maintenance Strategy

Choosing the right maintenance strategy involves evaluating TPM and RCM based on organizational goals and equipment criticality. TPM emphasizes proactive operator involvement and continuous improvements to maximize equipment effectiveness and reduce downtime, ideal for environments focusing on lean manufacturing. RCM prioritizes reliability by analyzing failure modes and implementing condition-based maintenance, making it suitable for industries where asset reliability and safety are paramount.

Autonomous Maintenance

Autonomous Maintenance in TPM empowers operators to perform routine equipment upkeep, enhancing daily operational reliability, whereas RCM prioritizes strategic maintenance based on risk and failure modes to optimize long-term asset performance.

Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is primarily integrated within Reliability-Centered Maintenance (RCM) to systematically identify and prioritize failure modes, whereas Total Productive Maintenance (TPM) emphasizes operator involvement and proactive equipment care without a formalized FMEA process.

Predictive Maintenance

Predictive Maintenance in TPM emphasizes continuous equipment monitoring to reduce downtime, while RCM uses failure mode analysis to prioritize maintenance based on reliability and safety impact.

Equipment Effectiveness (OEE)

Total Productive Maintenance (TPM) enhances Overall Equipment Effectiveness (OEE) through operator-driven proactive care and continuous improvement, while Reliability-Centered Maintenance (RCM) optimizes OEE by prioritizing maintenance based on functional failure modes and risk assessments.

Condition-Based Monitoring

Condition-Based Monitoring in Total Productive Maintenance emphasizes proactive equipment upkeep through operator involvement and continuous condition tracking, while Reliability-Centered Maintenance uses it as a critical strategy to prioritize maintenance tasks based on failure modes and asset criticality.

Preventive Maintenance Optimization

TPM emphasizes operator-driven preventive maintenance to maximize equipment efficiency, while RCM focuses on systematic preventive maintenance strategies based on reliability data to optimize asset performance and reduce failures.

Maintenance Task Analysis

Maintenance Task Analysis in TPM emphasizes proactive operator involvement and routine equipment care, while RCM focuses on systematic failure mode identification and prioritization to optimize maintenance strategies.

Root Cause Failure Analysis (RCFA)

Root Cause Failure Analysis (RCFA) in Reliability-Centered Maintenance (RCM) systematically identifies and addresses underlying equipment failures, whereas Total Productive Maintenance (TPM) emphasizes proactive operator involvement to prevent failures through routine maintenance activities.

Asset Criticality Assessment

Asset criticality assessment in TPM emphasizes overall equipment effectiveness to minimize downtime, while RCM prioritizes failure modes and risk analysis to optimize maintenance strategies based on asset criticality.

Maintenance Strategy Hierarchy

Total Productive Maintenance (TPM) emphasizes proactive, operator-driven maintenance within the Maintenance Strategy Hierarchy, while Reliability-Centered Maintenance (RCM) focuses on risk-based, condition-focused strategies to optimize asset reliability and performance.

TPM (Total Productive Maintenance) vs RCM (Reliability-Centered Maintenance) Infographic

njnir.com

njnir.com