Simulation modeling captures complex industrial processes by replicating real-world operations and allowing for dynamic scenario testing, which aids in understanding system behavior under varying conditions. Analytical modeling uses mathematical equations and formulas to provide precise, often closed-form solutions that are valuable for optimization and quick decision-making. Both approaches complement industrial engineering by balancing detailed system representation and computational efficiency in process improvement and resource allocation.

Table of Comparison

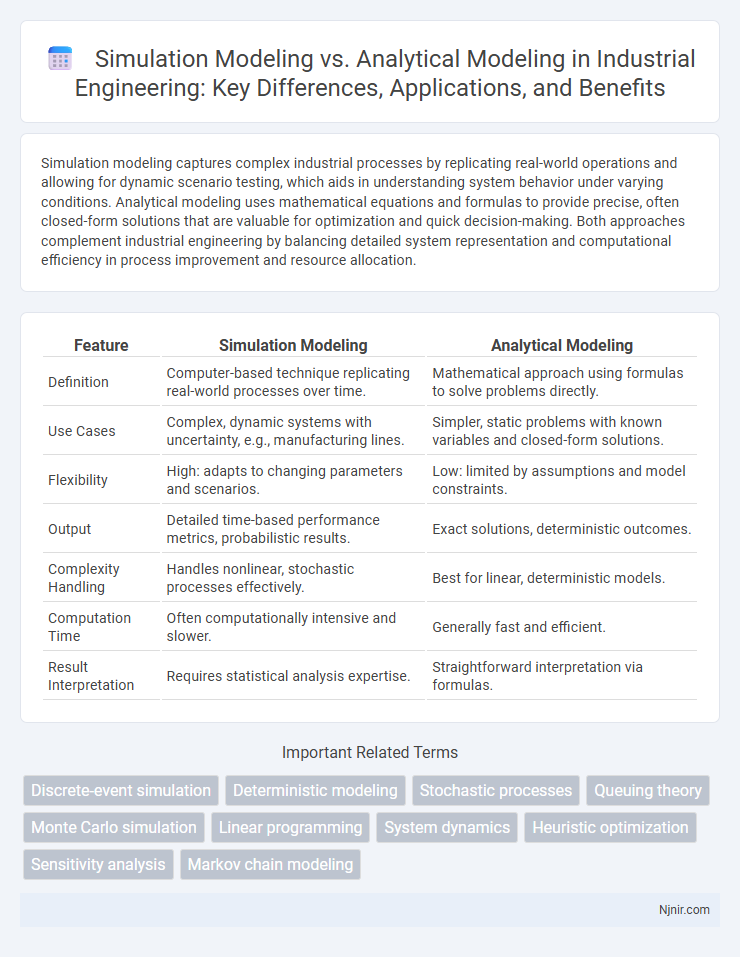

| Feature | Simulation Modeling | Analytical Modeling |

|---|---|---|

| Definition | Computer-based technique replicating real-world processes over time. | Mathematical approach using formulas to solve problems directly. |

| Use Cases | Complex, dynamic systems with uncertainty, e.g., manufacturing lines. | Simpler, static problems with known variables and closed-form solutions. |

| Flexibility | High: adapts to changing parameters and scenarios. | Low: limited by assumptions and model constraints. |

| Output | Detailed time-based performance metrics, probabilistic results. | Exact solutions, deterministic outcomes. |

| Complexity Handling | Handles nonlinear, stochastic processes effectively. | Best for linear, deterministic models. |

| Computation Time | Often computationally intensive and slower. | Generally fast and efficient. |

| Result Interpretation | Requires statistical analysis expertise. | Straightforward interpretation via formulas. |

Introduction to Simulation and Analytical Modeling in Industrial Engineering

Simulation modeling in industrial engineering enables the replication of complex systems to analyze dynamic processes and variability, providing insights into system performance under different scenarios. Analytical modeling uses mathematical equations and formulas to derive exact solutions for system behavior, offering precise, computationally efficient results for optimization and decision-making. Both methods are essential for process improvement, with simulation handling uncertainty and dynamics while analytical models excel in deterministic environments.

Fundamental Concepts of Simulation Modeling

Simulation modeling involves creating dynamic, time-dependent representations of real-world systems to analyze complex behaviors and variability, whereas analytical modeling relies on mathematical equations and closed-form solutions to describe system performance. Fundamental concepts of simulation modeling include entities, attributes, events, and resources, which interact over simulated time to mimic stochastic processes and system dynamics. This approach enables experimentation with different scenarios and system configurations without the constraints of simplifying assumptions inherent in analytical models.

Core Principles of Analytical Modeling

Analytical modeling relies on mathematical formulas and statistical methods to represent systems, enabling precise calculations and predictions based on defined assumptions. Core principles include defining variables, establishing relationships through equations, and solving these equations to derive insights about system behavior under various conditions. This approach emphasizes clarity, reproducibility, and often requires simplifying complex systems to maintain tractability.

Comparative Analysis: Strengths and Limitations

Simulation modeling excels in capturing complex, dynamic systems with stochastic variables, allowing detailed scenario analysis and experimentation under uncertainty. Analytical modeling provides precise, closed-form solutions that facilitate quick decision-making and sensitivity analysis but often requires simplifying assumptions that limit real-world applicability. Comparing both approaches reveals simulation's strength in flexibility and handling nonlinear, time-dependent processes, while analytical methods offer computational efficiency and clearer theoretical insights.

Application Areas in Industrial Engineering

Simulation modeling in industrial engineering is extensively applied for complex system analysis, such as manufacturing process optimization, logistics management, and supply chain design, where dynamic interactions and variability are critical. Analytical modeling is preferred for systems with well-defined mathematical relationships, facilitating cost estimation, quality control, and resource allocation through optimization techniques and queuing theory. Both approaches enhance decision-making by providing insights into performance evaluation, production scheduling, and inventory management in industrial environments.

Decision-Making Insights: Simulation vs Analytical Approaches

Simulation modeling provides dynamic, scenario-based decision-making insights by replicating complex systems and capturing variability and uncertainty over time. Analytical modeling relies on mathematical formulas and closed-form solutions to deliver precise, often static insights, ideal for problems with well-defined variables and constraints. Decision-makers benefit from simulation when evaluating systems with stochastic behavior, while analytical models excel in optimizing resource allocation under deterministic conditions.

Data Requirements and Model Complexity

Simulation modeling demands extensive data inputs to replicate real-world variability and dynamic interactions, often requiring large datasets for accurate scenario testing. Analytical modeling relies on simplified assumptions and mathematical formulas, necessitating less detailed data but potentially limiting real-world complexity representation. The complexity of simulation models is generally higher due to stochastic processes and iterative computations, whereas analytical models are typically more straightforward with closed-form solutions.

Accuracy and Validation of Modeling Techniques

Simulation modeling provides higher accuracy in complex systems by replicating dynamic interactions and stochastic variability, enabling detailed scenario analysis and iterative testing. Analytical modeling relies on mathematical equations and simplified assumptions, which can limit accuracy but allow for quicker validation through closed-form solutions and established theoretical frameworks. Validation of simulation models requires extensive data calibration and sensitivity analysis, whereas analytical models are typically validated through consistency with empirical data and theoretical soundness.

Computational Resources and Time Efficiency

Simulation modeling often requires significant computational resources and longer processing times due to its iterative nature and detailed scenario replication. Analytical modeling, relying on mathematical formulas, typically demands less computational power and delivers results more quickly, making it time-efficient for well-defined problems. Choosing between the two depends on the complexity of the system and the need for precision versus speed.

Future Trends in Industrial Engineering Modeling

Simulation modeling offers dynamic analysis of complex industrial systems by replicating real-world processes, enabling scenario testing and risk assessment with high accuracy. Analytical modeling relies on mathematical equations and optimization techniques to provide precise solutions for system design and performance evaluation but may oversimplify nonlinear interactions. Future trends emphasize hybrid approaches combining simulation and analytical models, leveraging artificial intelligence and big data to enhance predictive capabilities and decision-making in industrial engineering.

Discrete-event simulation

Discrete-event simulation models complex systems by representing state changes at specific events over time, offering detailed dynamic analysis compared to analytical modeling's reliance on mathematical equations and steady-state assumptions.

Deterministic modeling

Deterministic modeling in simulation provides dynamic scenario analysis by replicating real-world processes, while analytical modeling uses fixed equations and assumptions for precise but less flexible solutions.

Stochastic processes

Simulation modeling effectively captures the dynamic behavior of stochastic processes by mimicking random event sequences, whereas analytical modeling uses mathematical equations to derive probabilistic outcomes and steady-state characteristics.

Queuing theory

Simulation modeling captures dynamic, stochastic behaviors in queuing systems to analyze performance metrics under complex conditions, while analytical modeling uses mathematical formulas from queuing theory to provide exact, steady-state solutions for system parameters like arrival rates, service rates, and average wait times.

Monte Carlo simulation

Monte Carlo simulation provides robust stochastic analysis in simulation modeling by using random sampling to estimate complex probabilistic outcomes, whereas analytical modeling relies on deterministic mathematical equations for precise but often less flexible solutions.

Linear programming

Linear programming in analytical modeling provides exact optimization solutions through mathematical relationships, while simulation modeling approximates system behavior under varying scenarios without guaranteeing optimality.

System dynamics

System dynamics employs simulation modeling to analyze complex feedback loops and time delays within systems, offering dynamic behavior insights beyond the static equilibrium solutions provided by analytical modeling.

Heuristic optimization

Simulation modeling enables heuristic optimization by testing complex scenarios through iterative experimentation, while analytical modeling uses mathematical formulas to derive optimal solutions in structured heuristic optimization problems.

Sensitivity analysis

Sensitivity analysis in simulation modeling evaluates output variability by systematically varying input parameters, whereas in analytical modeling, it involves calculating explicit derivatives or gradients to assess the impact of parameter changes on model results.

Markov chain modeling

Markov chain modeling enhances analytical modeling by providing precise state-transition probabilities for complex stochastic processes, while simulation modeling approximates outcomes through iterative random sampling to analyze system behavior over time.

Simulation modeling vs Analytical modeling Infographic

njnir.com

njnir.com