Bottleneck analysis identifies the stage in a production process that limits overall throughput, allowing targeted improvements to increase efficiency. Root cause analysis delves deeper into underlying issues that create problems, aiming to prevent recurrence by addressing fundamental causes. Combining both methods provides a comprehensive approach to optimizing industrial processes and enhancing productivity.

Table of Comparison

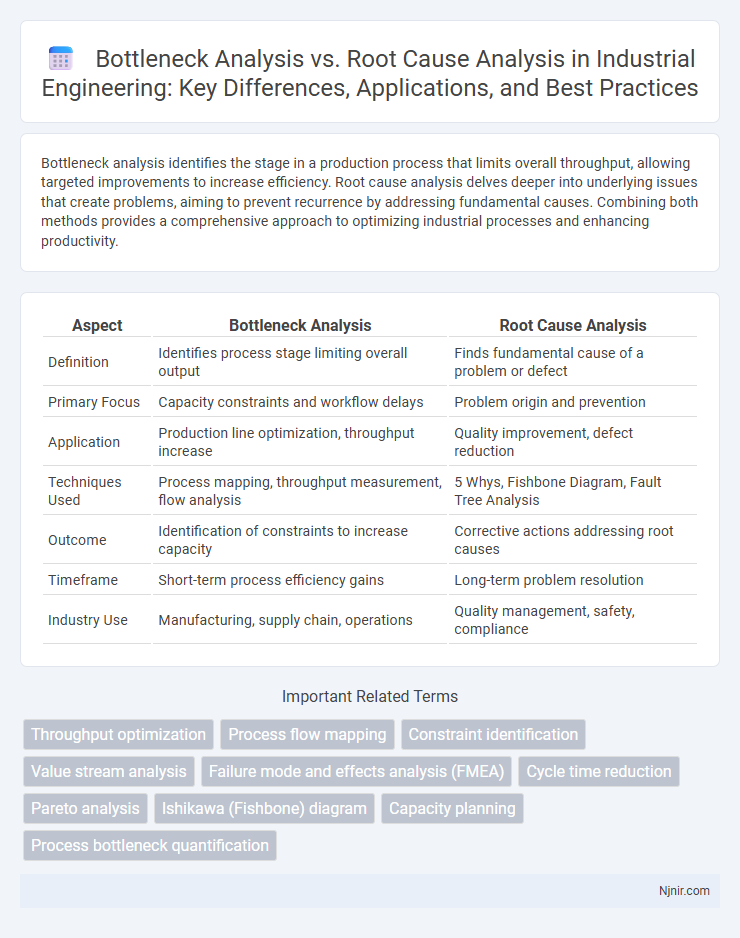

| Aspect | Bottleneck Analysis | Root Cause Analysis |

|---|---|---|

| Definition | Identifies process stage limiting overall output | Finds fundamental cause of a problem or defect |

| Primary Focus | Capacity constraints and workflow delays | Problem origin and prevention |

| Application | Production line optimization, throughput increase | Quality improvement, defect reduction |

| Techniques Used | Process mapping, throughput measurement, flow analysis | 5 Whys, Fishbone Diagram, Fault Tree Analysis |

| Outcome | Identification of constraints to increase capacity | Corrective actions addressing root causes |

| Timeframe | Short-term process efficiency gains | Long-term problem resolution |

| Industry Use | Manufacturing, supply chain, operations | Quality management, safety, compliance |

Introduction to Bottleneck and Root Cause Analysis

Bottleneck analysis identifies stages in a process where capacity limits restrict overall system throughput, focusing on optimizing flow and resource allocation to improve efficiency. Root cause analysis systematically investigates underlying causes of problems or failures, aiming to address fundamental issues rather than symptoms. Both methodologies enhance operational performance by targeting critical constraints or origins of defects to drive continuous improvement.

Definitions: Bottleneck Analysis vs Root Cause Analysis

Bottleneck analysis identifies points in a process where the flow is restricted, limiting overall performance and throughput. Root cause analysis investigates underlying reasons for a problem or failure by examining contributing factors to prevent recurrence. Both methodologies aim to improve efficiency but differ in focus: bottleneck analysis targets operational constraints, while root cause analysis addresses problem origins.

Key Objectives of Each Method

Bottleneck analysis primarily aims to identify the specific stage in a process that limits overall throughput, enabling targeted improvements to increase efficiency and productivity. Root cause analysis focuses on uncovering the underlying reasons for a problem or failure, facilitating long-term solutions by addressing the fundamental issues. Both methods serve distinct purposes: bottleneck analysis optimizes process flow, while root cause analysis ensures problem resolution and prevention.

Methodological Differences

Bottleneck analysis identifies the primary constraint limiting system performance by examining process flow and resource capacity, emphasizing throughput optimization. Root cause analysis systematically investigates underlying causes of a problem using techniques like the 5 Whys or Fishbone Diagram to prevent recurrence. Bottleneck analysis is process-centric and capacity-focused, while root cause analysis is problem-centric and causality-focused.

Tools and Techniques Used

Bottleneck analysis employs tools like process mapping and flowcharts to identify stages causing delays or reduced throughput, often using metrics such as cycle time and capacity utilization. Root cause analysis utilizes techniques including the 5 Whys, fishbone diagrams (Ishikawa), and Pareto charts to systematically uncover underlying causes of problems. Both methods integrate data collection and visualization but focus differently: bottleneck analysis targets process constraints, while root cause analysis digs deeper into problem origins.

Applications in Industrial Engineering

Bottleneck analysis in industrial engineering targets the identification and optimization of process constraints to enhance production flow and increase throughput rates. Root cause analysis systematically investigates underlying issues causing defects or delays, enabling long-term improvements in quality control and operational efficiency. Applying bottleneck and root cause analysis together facilitates comprehensive problem-solving, reduces downtime, and maximizes resource utilization in manufacturing environments.

Impact on Process Improvement

Bottleneck analysis identifies specific stages in a process where delays or capacity limits occur, enabling targeted improvements that enhance overall efficiency and throughput. Root cause analysis uncovers the fundamental issues causing process failures or inefficiencies, allowing organizations to implement corrective actions that prevent recurring problems and improve quality. Combining both methods drives comprehensive process improvements by addressing both symptoms and underlying causes.

Real-World Case Studies

Bottleneck analysis identifies process constraints limiting throughput, exemplified by Toyota's implementation in production lines that streamlined workflows and increased output by targeting the slowest stages. Root cause analysis delves deeper to uncover underlying issues, as demonstrated by NASA's investigation into the Challenger disaster that revealed the O-ring failure rooted in design flaws and environmental conditions. Real-world case studies highlight how bottleneck analysis optimizes operational efficiency, while root cause analysis prevents recurrence of critical failures through comprehensive problem-solving.

Advantages and Limitations

Bottleneck analysis offers advantages such as identifying the most significant constraint in a process that limits overall system performance, enabling targeted improvements to increase throughput and efficiency. Its limitation lies in focusing primarily on a single bottleneck, potentially overlooking other contributing factors or systemic issues. Root cause analysis provides the advantage of uncovering underlying causes of problems, facilitating long-term solutions and prevention, but it can be time-consuming and requires detailed data and expertise to accurately diagnose complex issues.

Selecting the Right Approach for Your Operation

Bottleneck analysis identifies constraints limiting overall process flow by pinpointing stages with the lowest throughput, which optimizes capacity and reduces delays. Root cause analysis digs deeper to uncover underlying issues causing recurring problems, aiming for long-term solutions and process improvements. Selecting the right approach depends on whether your operation requires immediate flow enhancement or a comprehensive resolution to systemic challenges.

Throughput optimization

Bottleneck analysis identifies the process stage limiting throughput to optimize overall system capacity, while root cause analysis targets underlying issues causing inefficiencies to improve throughput performance.

Process flow mapping

Bottleneck analysis identifies constraints in process flow mapping that limit throughput, while root cause analysis investigates underlying reasons for process inefficiencies to improve overall workflow performance.

Constraint identification

Bottleneck analysis identifies the primary constraint limiting process capacity by pinpointing slowest workflow stages, while root cause analysis investigates underlying reasons behind challenges to address and eliminate these constraints.

Value stream analysis

Value stream analysis identifies bottlenecks by mapping process flow and delays, while root cause analysis delves into underlying issues causing those bottlenecks to optimize overall value stream efficiency.

Failure mode and effects analysis (FMEA)

Bottleneck analysis identifies process constraints limiting throughput, while Root Cause Analysis (RCA) investigates underlying causes of failures, both essential in Failure Mode and Effects Analysis (FMEA) to prioritize and mitigate potential defects effectively.

Cycle time reduction

Bottleneck analysis identifies process constraints to reduce cycle time by optimizing throughput, while root cause analysis targets underlying issues causing delays to improve overall process efficiency.

Pareto analysis

Pareto analysis identifies key bottlenecks by highlighting the most significant causes in root cause analysis, enabling focused improvements on the critical 20% of issues that cause 80% of problems.

Ishikawa (Fishbone) diagram

Bottleneck analysis identifies process constraints limiting throughput, while Root Cause Analysis, often using the Ishikawa (Fishbone) diagram, systematically explores multiple potential causes like Methods, Machines, Materials, and Manpower to uncover underlying issues.

Capacity planning

Bottleneck analysis identifies capacity constraints limiting system throughput, while root cause analysis uncovers underlying issues affecting overall process performance in capacity planning.

Process bottleneck quantification

Process bottleneck quantification in bottleneck analysis measures throughput constraints by evaluating capacity limits, cycle times, and work-in-progress to identify process stages that restrict overall flow, whereas root cause analysis focuses on uncovering underlying reasons behind problems without primarily quantifying capacity.

Bottleneck analysis vs Root cause analysis Infographic

njnir.com

njnir.com