Batch production allows manufacturers to produce goods in specific quantities, enabling flexibility for product variation and customization. Continuous production operates nonstop, ensuring high efficiency and consistent output for large-scale manufacturing processes. Choosing between batch and continuous production depends on factors such as product demand, complexity, and production cost optimization.

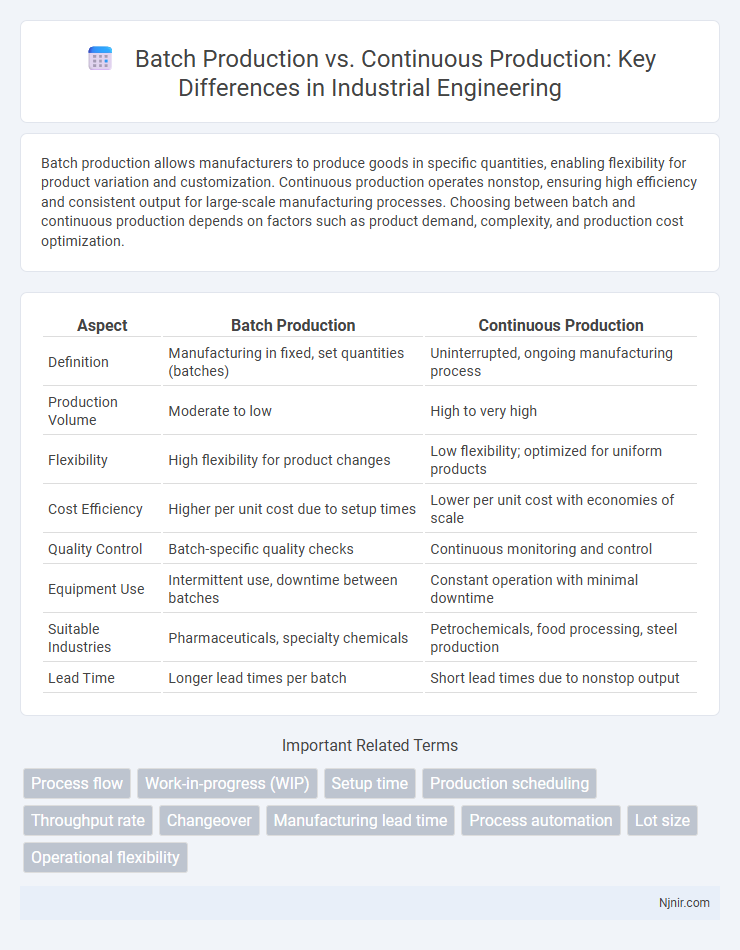

Table of Comparison

| Aspect | Batch Production | Continuous Production |

|---|---|---|

| Definition | Manufacturing in fixed, set quantities (batches) | Uninterrupted, ongoing manufacturing process |

| Production Volume | Moderate to low | High to very high |

| Flexibility | High flexibility for product changes | Low flexibility; optimized for uniform products |

| Cost Efficiency | Higher per unit cost due to setup times | Lower per unit cost with economies of scale |

| Quality Control | Batch-specific quality checks | Continuous monitoring and control |

| Equipment Use | Intermittent use, downtime between batches | Constant operation with minimal downtime |

| Suitable Industries | Pharmaceuticals, specialty chemicals | Petrochemicals, food processing, steel production |

| Lead Time | Longer lead times per batch | Short lead times due to nonstop output |

Introduction to Batch and Continuous Production

Batch production involves manufacturing goods in specific groups or quantities, allowing for customization and flexibility in processes. Continuous production operates through ongoing, non-stop manufacturing, ideal for high-volume, standardized products with consistent quality. Both methods optimize efficiency based on product type, market demand, and production capacity.

Key Differences Between Batch and Continuous Processes

Batch production involves manufacturing products in specific groups or quantities, allowing flexibility for customization and variation in product types, while continuous production runs non-stop, producing a consistent, high volume of standardized goods. Key differences include batch production's ability to accommodate changes between batches and lower initial setup costs, compared to continuous production's high efficiency, lower per-unit cost at scale, and reliance on automated processes. Batch processes are typically suited for smaller production runs and complex products, whereas continuous processes excel in large-scale, homogenous manufacturing environments.

Advantages of Batch Production

Batch production allows for greater flexibility in manufacturing different products or variations within the same production line, reducing changeover time and costs. It enables efficient quality control by identifying defects early within small batches, minimizing waste and rework. This method also supports customization and smaller production volumes, making it ideal for meeting varied customer demands without large inventory investment.

Advantages of Continuous Production

Continuous production offers high efficiency and consistent product quality by maintaining an uninterrupted manufacturing flow, which reduces downtime and operational costs. It enables large-scale output with minimal labor input and optimizes resource utilization, promoting economies of scale. This method is ideal for producing standardized products such as chemicals, petroleum, and food items with steady demand.

Limitations of Batch Production

Batch production faces limitations such as frequent downtime between batches, leading to reduced overall efficiency and increased labor costs. It is less suitable for high-volume manufacturing due to longer setup times and potential inconsistencies between batches. Additionally, the inventory of work-in-progress can be high, impacting storage requirements and cash flow.

Limitations of Continuous Production

Continuous production faces limitations such as high initial capital investment and inflexibility in adjusting to product variations or changes in demand. The process is prone to significant downtimes when equipment requires maintenance or breakdowns occur, impacting overall efficiency. It is less suitable for small batches or customized products due to its emphasis on standardized, high-volume outputs.

Application Areas for Batch and Continuous Production

Batch production is commonly applied in industries such as pharmaceuticals, food manufacturing, and specialty chemicals where product customization and variability are essential, enabling flexible production runs with varying formulas. Continuous production is primarily utilized in large-scale industries like petroleum refining, steel manufacturing, and paper production, where uninterrupted processes maximize efficiency and output quality over extended periods. These application areas highlight the suitability of batch production for diverse or seasonal products, while continuous production supports high-volume, consistent product streams.

Cost and Efficiency Comparison

Batch production offers lower initial setup costs and greater flexibility, making it cost-effective for small to medium production volumes but often results in higher per-unit costs due to downtime and changeover processes. Continuous production requires significant upfront capital investment and infrastructure but delivers superior efficiency and lower per-unit costs at large scales by minimizing interruptions and maximizing throughput. For businesses prioritizing cost control and efficiency, continuous production is optimal for high-volume, standardized products, while batch production suits diverse or seasonal manufacturing demands.

Quality Control in Batch vs Continuous Systems

Batch production allows for targeted quality control checks after each batch, enabling the identification and correction of defects before proceeding. Continuous production relies on real-time monitoring systems and automated controls to maintain consistent quality throughout the process, minimizing variability. Statistical Process Control (SPC) and inline sensors are critical in continuous systems to detect deviations promptly and reduce waste.

Choosing the Right Production Method for Industry

Batch production allows flexibility in manufacturing diverse products in specific quantities, making it ideal for industries with varying product demands or customization needs. Continuous production offers high efficiency and consistent output, best suited for industries with large-scale, standardized products such as chemicals or food processing. Selecting the right production method depends on factors like product type, volume requirements, and cost-efficiency targets within the industry.

Process flow

Batch production uses distinct, separate process flows for different production runs, while continuous production maintains an uninterrupted, streamlined process flow for consistent output.

Work-in-progress (WIP)

Batch production typically results in higher work-in-progress (WIP) inventory due to intermittent processing stages, while continuous production minimizes WIP by maintaining a steady, uninterrupted flow of materials.

Setup time

Batch production requires longer setup times due to frequent equipment adjustments, while continuous production minimizes setup time by maintaining constant operation.

Production scheduling

Batch production scheduling involves planning distinct production runs with downtime between batches, optimizing flexibility for varied products, while continuous production scheduling prioritizes uninterrupted operations with fixed, streamlined schedules to maximize efficiency and output consistency.

Throughput rate

Batch production typically has a lower throughput rate due to setup times between batches, while continuous production achieves a higher throughput rate by operating without interruptions.

Changeover

Batch production requires frequent and time-consuming changeovers between batches, while continuous production minimizes changeover interruptions to maintain steady output.

Manufacturing lead time

Batch production typically has longer manufacturing lead times due to setup and changeover between batches, whereas continuous production minimizes lead time by operating nonstop with consistent workflow.

Process automation

Process automation enhances efficiency in continuous production by enabling nonstop operations, whereas batch production automation focuses on flexible control for discrete product runs.

Lot size

Batch production typically involves moderate lot sizes tailored for variety and flexibility, whereas continuous production emphasizes large lot sizes optimized for high-volume, uninterrupted output.

Operational flexibility

Batch production offers higher operational flexibility by allowing easy adjustment of product types and volumes, whereas continuous production prioritizes efficiency with limited flexibility.

Batch production vs Continuous production Infographic

njnir.com

njnir.com