Industrial Internet of Things (IIoT) enhances traditional Internet of Things (IoT) applications by integrating advanced sensor technology and real-time data analytics specifically tailored for industrial environments. IIoT drives increased operational efficiency, predictive maintenance, and improved asset management through robust connectivity and secure communication protocols. This specialization distinguishes IIoT from general IoT by prioritizing industrial process optimization and workplace safety.

Table of Comparison

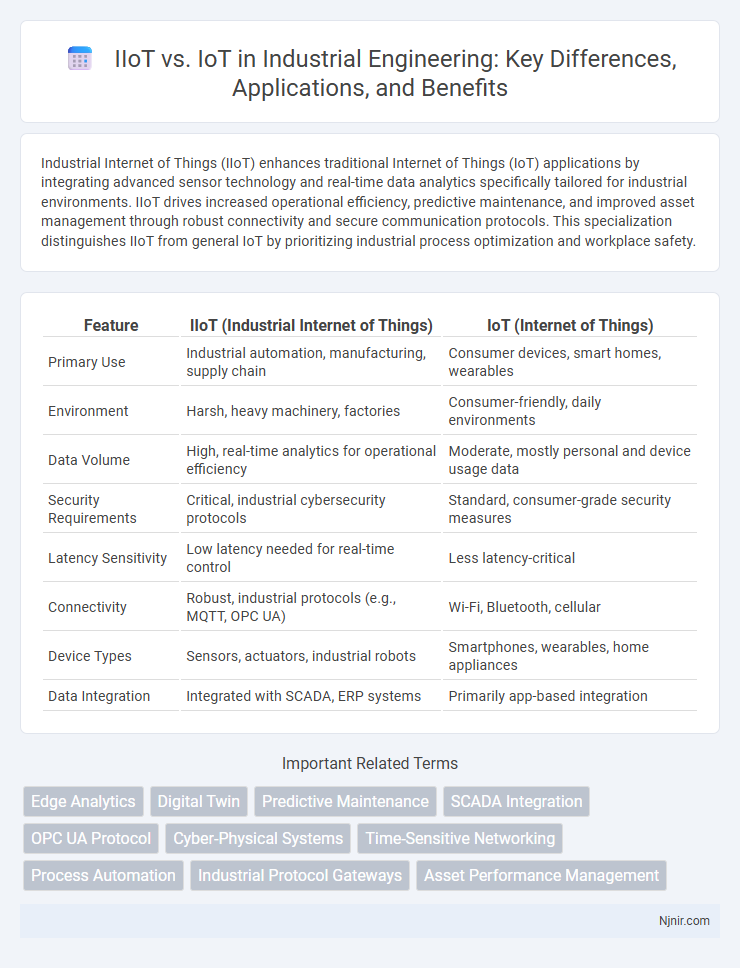

| Feature | IIoT (Industrial Internet of Things) | IoT (Internet of Things) |

|---|---|---|

| Primary Use | Industrial automation, manufacturing, supply chain | Consumer devices, smart homes, wearables |

| Environment | Harsh, heavy machinery, factories | Consumer-friendly, daily environments |

| Data Volume | High, real-time analytics for operational efficiency | Moderate, mostly personal and device usage data |

| Security Requirements | Critical, industrial cybersecurity protocols | Standard, consumer-grade security measures |

| Latency Sensitivity | Low latency needed for real-time control | Less latency-critical |

| Connectivity | Robust, industrial protocols (e.g., MQTT, OPC UA) | Wi-Fi, Bluetooth, cellular |

| Device Types | Sensors, actuators, industrial robots | Smartphones, wearables, home appliances |

| Data Integration | Integrated with SCADA, ERP systems | Primarily app-based integration |

Introduction to IoT and IIoT

The Internet of Things (IoT) refers to a network of interconnected devices that collect and exchange data to enhance personal and business applications. Industrial Internet of Things (IIoT) specifically applies IoT technologies to industrial environments, improving operational efficiency, predictive maintenance, and automation in sectors like manufacturing, energy, and transportation. IIoT integrates sensors, machines, and analytics to optimize industrial processes with real-time data insights.

Key Differences Between IoT and IIoT

The Industrial Internet of Things (IIoT) primarily targets industrial environments, emphasizing machine-to-machine communication, real-time analytics, and enhanced operational efficiency, unlike the Internet of Things (IoT) which focuses on consumer applications such as smart homes and wearable devices. IIoT systems utilize robust, industrial-grade sensors and devices to monitor manufacturing processes, supply chains, and infrastructure, driving predictive maintenance and minimizing downtime. Security protocols and data integration in IIoT are more stringent due to critical infrastructure risks, whereas IoT prioritizes user convenience and connectivity across everyday consumer products.

Core Technologies in IIoT and IoT

IIoT leverages core technologies such as industrial-grade sensors, edge computing, and advanced analytics tailored for real-time process optimization and predictive maintenance in manufacturing environments. IoT primarily utilizes consumer-oriented devices, cloud computing, and wireless connectivity to enable smart home automation and personal device interconnectivity. While both share foundational technologies like IoT protocols (MQTT, CoAP) and data communication standards, IIoT emphasizes robust security, scalability, and interoperability to meet stringent industrial demands.

Industrial Engineering Applications of IIoT

Industrial Internet of Things (IIoT) enhances traditional Internet of Things (IoT) by integrating smart sensors, machine learning, and big data analytics into industrial systems, enabling real-time monitoring and predictive maintenance. IIoT applications in industrial engineering optimize production processes, improve resource management, and increase operational efficiency through automated control systems and digital twins. This connectivity reduces downtime, lowers costs, and facilitates advanced decision-making in manufacturing, energy, and supply chain management sectors.

Benefits of IIoT Over Traditional IoT in Industry

IIoT leverages industrial-grade sensors and real-time data analytics to enhance operational efficiency, reduce downtime, and optimize supply chain management across manufacturing and heavy industries. Unlike traditional IoT, IIoT incorporates advanced predictive maintenance, ensuring critical machinery reliability and extended equipment lifespan. Enhanced security protocols and integration with industrial control systems provide IIoT with superior resilience against cyber threats compared to standard consumer-focused IoT solutions.

Data Security and Privacy Concerns in IIoT vs IoT

Data security and privacy concerns in IIoT (Industrial Internet of Things) are significantly heightened compared to general IoT due to the critical nature of industrial systems and the massive volume of sensitive operational data involved. IIoT networks often require advanced encryption, real-time threat detection, and strict access controls to protect against cyber-attacks that could disrupt industrial processes or lead to catastrophic failures. Privacy issues in IIoT focus more on safeguarding proprietary industrial data, whereas IoT privacy typically centers on personal user data protection, necessitating tailored security protocols unique to industrial environments.

Scalability and Integration Challenges

IIoT systems demand higher scalability due to the vast number of industrial devices and sensors requiring real-time data processing and analytics across extensive networks. Integration challenges arise from the need to connect legacy industrial equipment with modern IIoT platforms while ensuring data security and interoperability. Unlike general IoT, IIoT must prioritize robust protocols and scalable infrastructure to handle mission-critical operations and complex industrial workflows.

Real-time Data Processing: IoT vs IIoT

Industrial Internet of Things (IIoT) prioritizes real-time data processing to optimize manufacturing efficiency, predictive maintenance, and operational safety through robust sensor networks and edge computing. In contrast, general IoT applications often handle less time-sensitive data for consumer devices like smart homes and wearables, where slight delays are acceptable. The IIoT's stringent latency requirements drive the adoption of advanced protocols and local analytics to enable immediate decision-making and minimize downtime in industrial environments.

Predictive Maintenance Enabled by IIoT

Predictive maintenance leverages IIoT's advanced sensors and real-time data analytics to monitor industrial equipment health, reducing unplanned downtime and maintenance costs. Unlike general IoT, IIoT integrates specialized protocols and ruggedized devices designed for harsh industrial environments, ensuring higher reliability and precision. This enables proactive asset management, optimizing operational efficiency and extending machinery lifespan through early fault detection and condition-based maintenance.

Future Trends in IIoT for Industrial Engineering

Future trends in IIoT for industrial engineering emphasize increased integration of artificial intelligence and machine learning to enhance predictive maintenance and optimize supply chain processes. The adoption of 5G networks enables real-time data transmission, improving operational efficiency and safety in manufacturing environments. Cybersecurity advancements tailored for IIoT ensure protection against evolving threats while maintaining system reliability and data integrity in industrial applications.

Edge Analytics

Edge analytics in IIoT processes industrial data locally on devices to enable real-time insights and reduced latency, unlike IoT, which often relies on centralized cloud computing.

Digital Twin

Digital Twins in IIoT enable real-time industrial asset monitoring and predictive maintenance, surpassing IoT applications by providing detailed simulations and operational insights for complex manufacturing environments.

Predictive Maintenance

Industrial Internet of Things (IIoT) enhances predictive maintenance by leveraging real-time sensor data and advanced analytics to reduce equipment downtime, whereas Consumer Internet of Things (IoT) primarily focuses on automation and convenience for personal devices.

SCADA Integration

IIoT enhances SCADA integration by enabling real-time data analytics, improved predictive maintenance, and seamless connectivity with industrial devices, outperforming traditional IoT systems in industrial automation.

OPC UA Protocol

OPC UA protocol ensures secure, reliable industrial communication in IIoT applications, offering enhanced interoperability and data modeling compared to IoT protocols.

Cyber-Physical Systems

Cyber-Physical Systems are integral to IIoT, enabling real-time integration of physical processes with digital communication, which distinguishes IIoT from consumer-focused IoT applications.

Time-Sensitive Networking

Time-Sensitive Networking (TSN) enhances IIoT by providing deterministic, low-latency communication crucial for industrial automation, unlike general IoT applications where such stringent timing is less critical.

Process Automation

IIoT enhances process automation by integrating industrial-grade sensors and real-time data analytics to optimize manufacturing efficiency, whereas IoT primarily connects consumer devices for convenience and data collection.

Industrial Protocol Gateways

Industrial Protocol Gateways enable seamless communication between diverse legacy IIoT systems and modern IoT networks by translating industrial protocols like Modbus, OPC UA, and PROFIBUS for enhanced interoperability and real-time data exchange.

Asset Performance Management

Industrial Internet of Things (IIoT) enhances Asset Performance Management by providing real-time sensor data, predictive analytics, and remote monitoring, surpassing general IoT applications in optimizing industrial equipment efficiency and reducing downtime.

IIoT vs IoT Infographic

njnir.com

njnir.com